The good thing about the MB mod is that you just buy the standard steel mailbox - cheaper the better. For vents - drill holes in bottom and along sides all the way around for air. Also - put your AMPNS on "stilts" - screws thru it to act like legs elevating it above the mailbox floor.

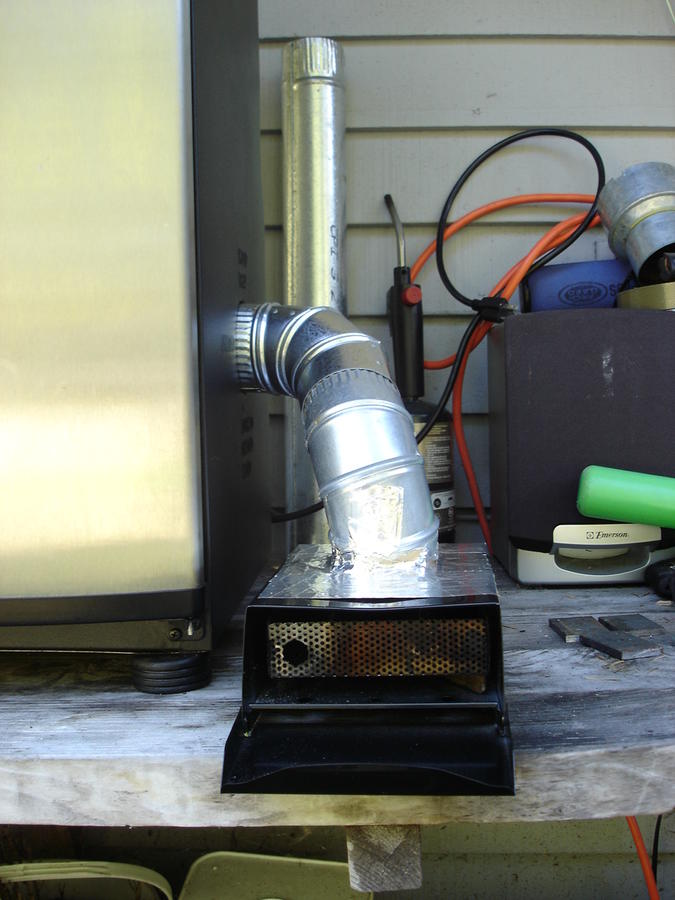

Buy two 90 degree elbows and a length of the straight tubing and some duct tape.

Cut the hole in the top of the mailbox as far to the end (Away from the door) and connect everything. The 90Degree elbows are rotatable, so it don't need to be perfect.

When you put the AMPNS in, (The greatest invention ever) put all the way in back - but first.....

Turn your MES to 275, fill your AMPNS with the pellets - I found each straight row lasts 2 hrs and place in MES for 30 mins. (This also gets the MES sterile, and ready.

Turn the MES to 225, or whatever temp you have to cook at. Put the AMPNS at the front of the mailbox and light with a torch. Lets burn ofr 2-3 mins, and blow out. Blow on it a little bit to keep ambers going and place the AMPNS all the way back. Be careful, cause the front will be a little hot where flame was, so....

Of course, all this needs to be done after removing the innards of the smoke tray and chip loader. Make sure you cover your heating element correctly.

Buy two 90 degree elbows and a length of the straight tubing and some duct tape.

Cut the hole in the top of the mailbox as far to the end (Away from the door) and connect everything. The 90Degree elbows are rotatable, so it don't need to be perfect.

When you put the AMPNS in, (The greatest invention ever) put all the way in back - but first.....

Turn your MES to 275, fill your AMPNS with the pellets - I found each straight row lasts 2 hrs and place in MES for 30 mins. (This also gets the MES sterile, and ready.

Turn the MES to 225, or whatever temp you have to cook at. Put the AMPNS at the front of the mailbox and light with a torch. Lets burn ofr 2-3 mins, and blow out. Blow on it a little bit to keep ambers going and place the AMPNS all the way back. Be careful, cause the front will be a little hot where flame was, so....

Of course, all this needs to be done after removing the innards of the smoke tray and chip loader. Make sure you cover your heating element correctly.