Thanks. It does have some weight to it lol. I am gonna put it on golf cart hubs, wheels and tires. They weight on average 800 to 1100 lbs. this will certainly be in that ball park. Figures I will make a handle to pull it around. I want to make it removable and make I trailer hitch so I could hook it to my sxs if needed. I have the trailer hitch parts laying around. When I buy the 2x2 steel for the base I should have leftovers to build those. Good eye on the reqtec. I have had it like 5yrs now. Works great.Tank looks like it will be a winner for this setup. Looks heavy though. Are you planning on making a trailer for it or just some wheels. Cool project though. :)

Also is that a recteq bullseye in there I see?

Added pic My first reverse flow smoker build

- Thread starter irvin78787884

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Thanks. It does have some weight to it lol. I am gonna put it on golf cart hubs, wheels and tires. They weight on average 800 to 1100 lbs. this will certainly be in that ball park. Figures I will make a handle to pull it around. I want to make it removable and make I trailer hitch so I could hook it to my sxs if needed. I have the trailer hitch parts laying around. When I buy the 2x2 steel for the base I should have leftovers to build those. Good eye on the reqtec. I have had it like 5yrs now. Works great.

Ah ok. That would be cool to be able to trailer it if you wanted to, but also just move it by hand as well. :)

Kinda my thoughts. I have a trailer already and don’t have room for a second so as long as I can load it on my trailer and haul it if need I will be good to go.Ah ok. That would be cool to be able to trailer it if you wanted to, but also just move it by hand as well. :)

Well put in a few hours today cut out the rusted holes. Cut out extra to be sure I got it all might actually cut some of the good usable metal off and put it back. Also got 3/4 of the paint removed. Now gotta spin the tank to get the rest off. That will be next time.

Attachments

Hello RedGood morning Irvin.

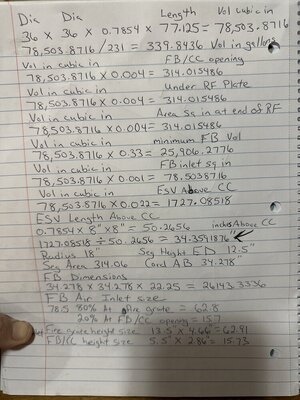

If I'm reading your calculations correctly, you have a FB that's about 105% of the recommended volume? That's a pretty good number. I've been told by more experienced pitmakers than myself that the "sweet spot" is between 100 and 107% for FB volume.

So it seems to me you're on the right track.

Red

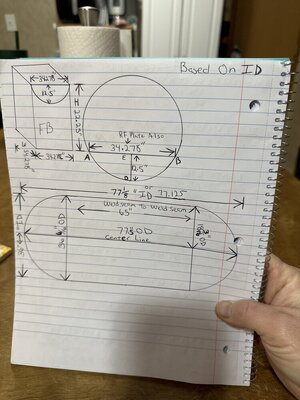

If u get a few mins can u look over my new actual inside number/calculations to be sure I am good. One thing I especially wonder is the fb inlets. Looking for the 80% at fire height and then 20% at Fb/CC opening height. I think the rest are good. I just want more eyes on it to be sure. All the new stuff is on page 2 I believe. Also and maybe this is a stupid question and my brain is over thinking it. How or what’s the easy way to get exact center horizontal and vertical line on the ends of the tank. It’s rounded in multiple directions and u can’t just put tape measure on it like it was flat. Thank for the help.

Tom

I use a level on both sides. Make sure they are both plum. And then measure the distance between the two. Divide that in half and then measure from one level to the center.

I make sure the tank is sitting level at all times. Then you can use a level for drawing horizontal lines

Ok thanks I will certainly give that a try I was thinking it. Just gotta get it right lolI make sure the tank is sitting level at all times. Then you can use a level for drawing horizontal lines

Hello Red

If u get a few mins can u look over my new actual inside number/calculations to be sure I am good. One thing I especially wonder is the fb inlets. Looking for the 80% at fire height and then 20% at Fb/CC opening height. I think the rest are good. I just want more eyes on it to be sure. All the new stuff is on page 2 I believe. Also and maybe this is a stupid question and my brain is over thinking it. How or what’s the easy way to get exact center horizontal and vertical line on the ends of the tank. It’s rounded in multiple directions and u can’t just put tape measure on it like it was flat. Thank for the help.

Tom

Good morning Tom. Not sure what "page 2" you're talking about. I went to your original link to your Felton's calculator numbers and don't see a pg. 2. Sorry if I'm missing something...

I'd say you're on the right track with designing your fb damper/inlet at - or near - fire height. I like to go with 2 smaller dampers myself instead of 1 larger one...but I try to place those right at fire height.

Red

Ok I was meaning page 2 of this thread. It’s the pictures of the paper with the formulas all written out. These are the actual inside of tank measurements. I will add the pics to this replay. Thanks for ur help tho. Much appreciated.Good morning Tom. Not sure what "page 2" you're talking about. I went to your original link to your Felton's calculator numbers and don't see a pg. 2. Sorry if I'm missing something...

I'd say you're on the right track with designing your fb damper/inlet at - or near - fire height. I like to go with 2 smaller dampers myself instead of 1 larger one...but I try to place those right at fire height.

Red

Attachments

Just went and picked up a 11’x7.5’ steel pallet. It’s got 4 11’ long and 2 7.5’ long 2”x4” 1/8 wall rectangle tube that I will use to build the base for the smoker also has some C channel and angle iron pieces as well. Can’t wait till Saturday and Sunday to spend some time working on the smoker.

Attachments

Just went and picked up a 11’x7.5’ steel pallet. It’s got 4 11’ long and 2 7.5’ long 2”x4” 1/8 wall rectangle tube that I will use to build the base for the smoker also has some C channel and angle iron pieces as well. Can’t wait till Saturday and Sunday to spend some time working on the smoker.

Nice score on that pallet! There's a lot of good reusable material in that. It's always nice to find used material that can be repurposed.

Red

For sure and the cost savings is nice also. It did cost me $150. If I went and bought the 2x4 steel alone would have cost double or a little more cause I know 2 sticks of 2x2 was $240 plus had to drive an hour for it.Nice score on that pallet! There's a lot of good reusable material in that. It's always nice to find used material that can be repurposed.

Red

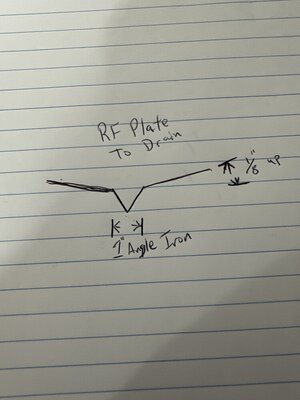

I have another question. Sorry i have lots. lol Anyways if I angle my RF plate say 1/8” up and put a piece of 1” angle iron in the center to drain the juices from cooks. Will I need to adjust any of the build numbers to account for that. Similar to the drawing below. Got the steel pallet almost all cut apart today. No pictures as it was dark when I was finished for the night.

Attachments

if I angle my RF plate say 1/8” up

Angle all you want... Just make the lowest point of your angled/slope the minimum hieght of the RF plate... So this will make your fish mouth cut out higher...

Ok thanks. If I decide to do it I will make sure the end of it is the 12.5” height that it supposed to be.Angle all you want... Just make the lowest point of your angled/slope the minimum hieght of the RF plate... So this will make your fish mouth cut out higher...

Didn’t work on smoker unfortunately and the weather was decent last 2 days in PA. It wasn’t a total loss tho. I tried to work on it Friday night but the 110v welder and 110v plasma kept tripping the breakers. Not ran at same time obviously. It’s a long run for the normal 12/2 wire and I never gave it a consideration. So the shed is in process of getting and new 2awg wire run and it’s own sub panel. I will be able to run the plasma on 220v the welder is only a 110v tho.

Attachments

Last edited:

I did get all the wiring done for the shed. Got to use the plasma cutter and started to cut the baffles inside that stopped the water that was in it from sloshing around. Need to cut the in the area of the cc door. That way when I cut that I can remove it. Then once I get inside I can finish removing them. No pics tho sorry.

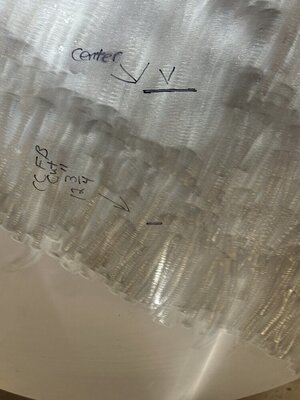

Worked on it for 2 hrs tonight tille I had to make dinner for the family. Got the tank rotated to the location I wanted for lay out. I made a thing to lift it to rotate it out of a 4x4 and some 2x6. Worked well. I got the center line marked and the 12.75” line for the cc to fb cut. It’s supposed to be 12.5” the extra 1/4” is the fb metal thickness. Hopefully I will make more progress each day this week and weekend Pa weather is looking ok to work in the non heated shed.

Attachments

- Jan 8, 2024

- 48

- 30

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 37

- Views

- 1K

- Replies

- 4

- Views

- 542

- Replies

- 13

- Views

- 644

- Replies

- 11

- Views

- 785

- Replies

- 2

- Views

- 716

Hot Threads

-

Leg O’ Lamb

- Started by SmokinEdge

- Replies: 36

- Lamb

-

Kielbasa...

- Started by Gonna Smoke

- Replies: 33

- Sausage

-

Bricked iPhone 14

- Started by BGKYSmoker

- Replies: 33

- General Discussion

-

What Is Something You could Not Live Without In The Kitchen?

- Started by KBFlyer

- Replies: 32

- Blowing Smoke Around the Smoker.