Hello Gentlemen,

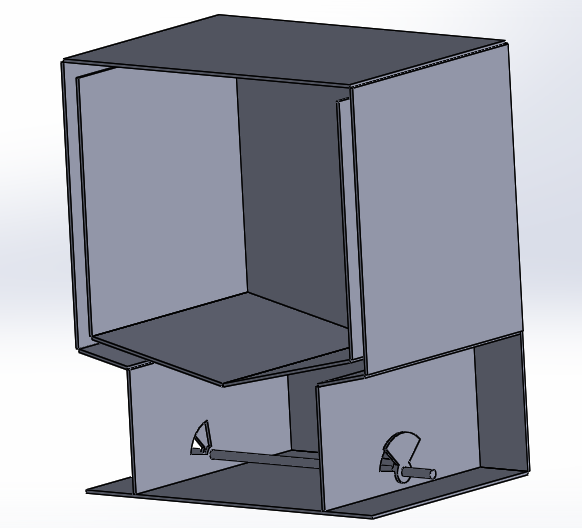

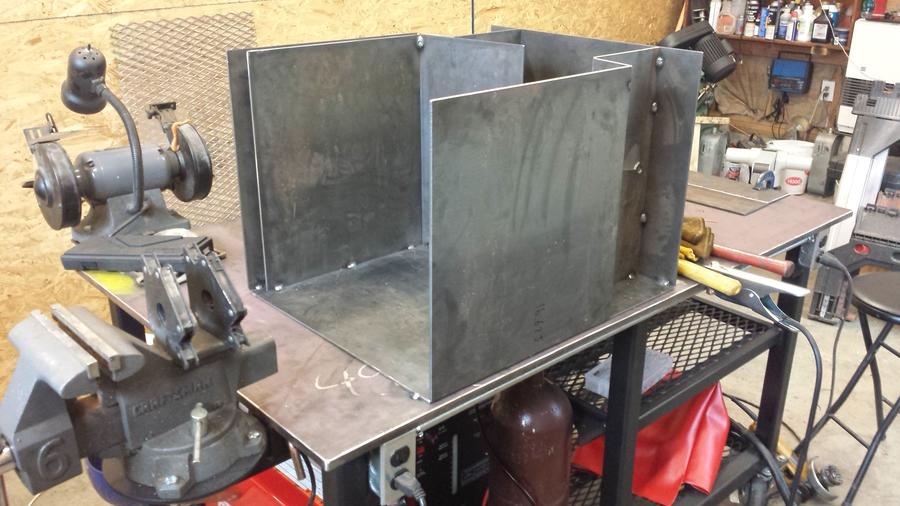

I've been lurking for a while and thought I'd make a post as I am looking for some opinions as I have not smoked before. I was going to by a WSM but I do a ton of fabrication on the side and have a some 24" wide sheets of 3/16" left over and want to make a smoker with the remaining. I wanted it to be small since I have too much crap as it is and won't be feeding an army. I also plan to automate it as well (just the damper for now) with HVAC controls which is my day gig.

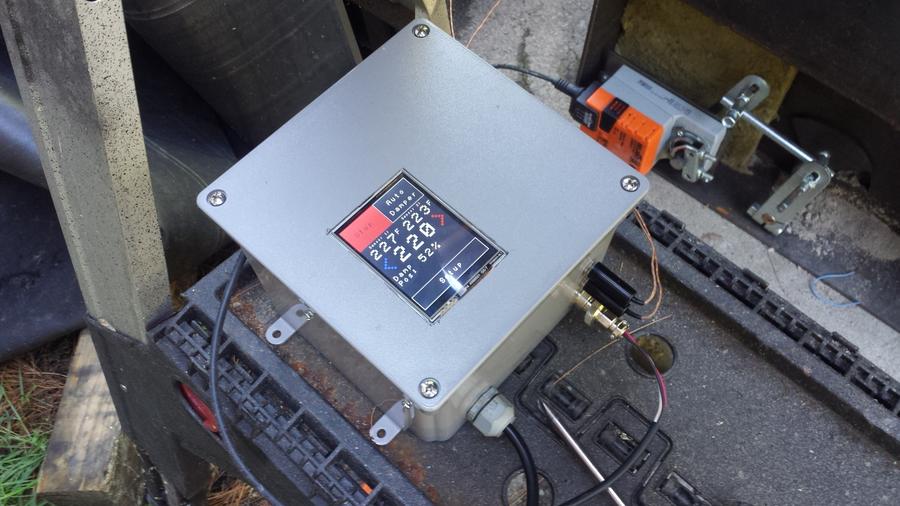

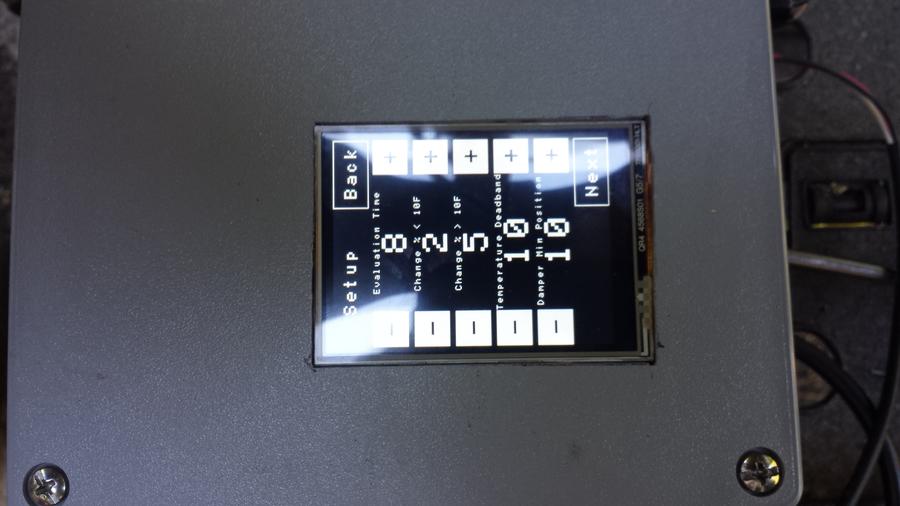

Where the little dampers are will be an actuator on one side and transformer and controller on the other side on either side of the shaft. I have done all the math and I am right where it should be according to http://www.feldoncentral.com/bbqcalculator.html I have also made the depth 14" as a starting point if the scrap I have left allows me deeper, I will do that. Just getting things going first.

Off to my questions:

1.) My FB is in proportion to the CC. This will only leave a 5" x 13" x 14" charcoal basket after clearing the damper shaft and leaving room for ash. What kind of run time would you guess at 225F? Looking for opinions because the FB/CC ratio is right but I feel like my charcoal basket will be small for a 4100 cu in CC.

2.) The math says I need a pretty good size opening for the exhaust but I don't want to mount on the outside because I want to use this year round. If it is inside of the cook chamber, anyone know if I can make the exhaust smaller in diameter since it will be warm the whole length if tube? May insulate and place outside as well. I have not decided.

Plan is to insulate and finish over in 16ga. That's my reason for the indents in the bottom so it hides all the controls for a better look. There will be intake louvers in the 16 ga so it can run in the indents to the dampers.

Thanks for your time and great forum.

I've been lurking for a while and thought I'd make a post as I am looking for some opinions as I have not smoked before. I was going to by a WSM but I do a ton of fabrication on the side and have a some 24" wide sheets of 3/16" left over and want to make a smoker with the remaining. I wanted it to be small since I have too much crap as it is and won't be feeding an army. I also plan to automate it as well (just the damper for now) with HVAC controls which is my day gig.

Where the little dampers are will be an actuator on one side and transformer and controller on the other side on either side of the shaft. I have done all the math and I am right where it should be according to http://www.feldoncentral.com/bbqcalculator.html I have also made the depth 14" as a starting point if the scrap I have left allows me deeper, I will do that. Just getting things going first.

Off to my questions:

1.) My FB is in proportion to the CC. This will only leave a 5" x 13" x 14" charcoal basket after clearing the damper shaft and leaving room for ash. What kind of run time would you guess at 225F? Looking for opinions because the FB/CC ratio is right but I feel like my charcoal basket will be small for a 4100 cu in CC.

2.) The math says I need a pretty good size opening for the exhaust but I don't want to mount on the outside because I want to use this year round. If it is inside of the cook chamber, anyone know if I can make the exhaust smaller in diameter since it will be warm the whole length if tube? May insulate and place outside as well. I have not decided.

Plan is to insulate and finish over in 16ga. That's my reason for the indents in the bottom so it hides all the controls for a better look. There will be intake louvers in the 16 ga so it can run in the indents to the dampers.

Thanks for your time and great forum.