- Oct 2, 2014

- 5

- 10

G-day Team

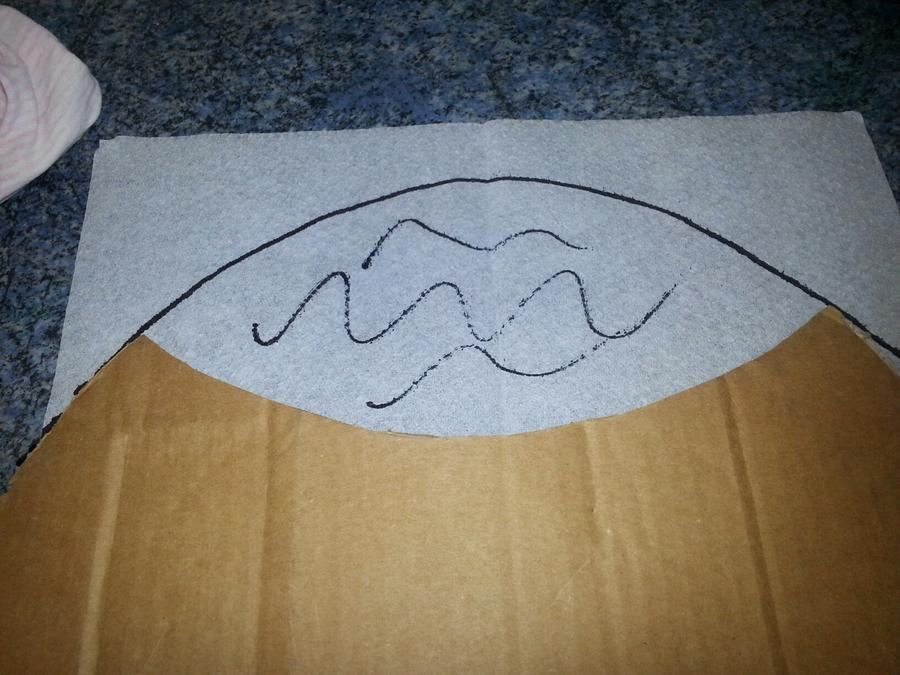

Just looking for some guidance/advice on my smoker. I have tried to build it according to Feldon calculator. Still not sure i nailed it with the CC to FB opening. Anyway I have fired it up 2 x and both times if i leave the stack wide open and the FB vents wide open it reach's 300 degrees, but when I try to start to shut things down (even slightly)it drops to 200 or just below. I have a plate inside to send the heat to the left side of the smoker. Should I have holes drilled in it. Would these few things have bearing on temp control. No fire proof gasket on doors and it is quite a loose fit, my grease trap is not sealed, i find i get quite a bit of ash in the bottom of the fire box and I am sure it reduces air flow. I will attach some photo's. looking forward to reading your thoughts/suggestions.

Thanks in advance

Just looking for some guidance/advice on my smoker. I have tried to build it according to Feldon calculator. Still not sure i nailed it with the CC to FB opening. Anyway I have fired it up 2 x and both times if i leave the stack wide open and the FB vents wide open it reach's 300 degrees, but when I try to start to shut things down (even slightly)it drops to 200 or just below. I have a plate inside to send the heat to the left side of the smoker. Should I have holes drilled in it. Would these few things have bearing on temp control. No fire proof gasket on doors and it is quite a loose fit, my grease trap is not sealed, i find i get quite a bit of ash in the bottom of the fire box and I am sure it reduces air flow. I will attach some photo's. looking forward to reading your thoughts/suggestions.

Thanks in advance