- Nov 23, 2017

- 3

- 0

I wanted to pass on my mod for controlling Heat and smoke independently. I feel this mod makes the best home smoker you can get.

I removed the entire apparatus that lets you slide wood chips in. It is located on the right side of the unit, plus the supporting structure inside the unit.

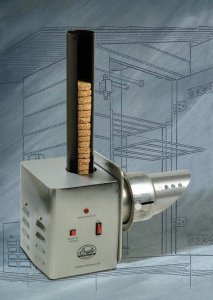

I installed a Bradley Smoke Generator BTSG1 on the left side of the unit. Just cut a whole, slide the mounting sleeve through the hole, done.

I used the insulation from installing the Bradley and aluminum cut from a disposable roasting pan to fill the hole left by removing the wood chip slide. I used pop rivets for that.

This lets me control the heat and smoke independent of each other.

I can do a variety of different kinds of smoking.

I can load up the hopper and walk away for 9 hours.

I can smoke with no heat.

I can smoke low and slow.

I can smoke at high heat.

I can smoke for the first two hours, and opt not to smoke for the rest of the time.

I can alternate kinds of wood such as alternating cherry with apple every 20 minutes.

I can put a brisket in, walk away for 20 hours, come back, open the door and eat it!

The Bradley smoker is way too small.

The big MES is big enough, has great insulation, and has digital temperature controls, but is just not the best at making smoke.

* Helpful Note: Store the Bradley generator on a shelf in your garage. It has issues when the unit itself is below 32 degrees when it is initially turned on. Once it is on, it is fine irregardless of the surrounding temperature. I have smoked to -10 degrees.

I removed the entire apparatus that lets you slide wood chips in. It is located on the right side of the unit, plus the supporting structure inside the unit.

I installed a Bradley Smoke Generator BTSG1 on the left side of the unit. Just cut a whole, slide the mounting sleeve through the hole, done.

I used the insulation from installing the Bradley and aluminum cut from a disposable roasting pan to fill the hole left by removing the wood chip slide. I used pop rivets for that.

This lets me control the heat and smoke independent of each other.

I can do a variety of different kinds of smoking.

I can load up the hopper and walk away for 9 hours.

I can smoke with no heat.

I can smoke low and slow.

I can smoke at high heat.

I can smoke for the first two hours, and opt not to smoke for the rest of the time.

I can alternate kinds of wood such as alternating cherry with apple every 20 minutes.

I can put a brisket in, walk away for 20 hours, come back, open the door and eat it!

The Bradley smoker is way too small.

The big MES is big enough, has great insulation, and has digital temperature controls, but is just not the best at making smoke.

* Helpful Note: Store the Bradley generator on a shelf in your garage. It has issues when the unit itself is below 32 degrees when it is initially turned on. Once it is on, it is fine irregardless of the surrounding temperature. I have smoked to -10 degrees.

Last edited: