Hi All,

So I have been Hot Smoking, BBQ;) for about 2.5 Years now. I have outgrown my electric bullet smoker and my Smoke Hollow 4 in 1. I do a lot of browsing on this forum but haven't posted much. I had intentions on making one out of an old propane tank (as many do) but I have not the skills to do such. So I thought I would make one out of Concrete block. I come from an architectural background and have drawn it up in autocad and would like any feedback any members have. below are some images i generated and splashed a bit of color on in photoshop.

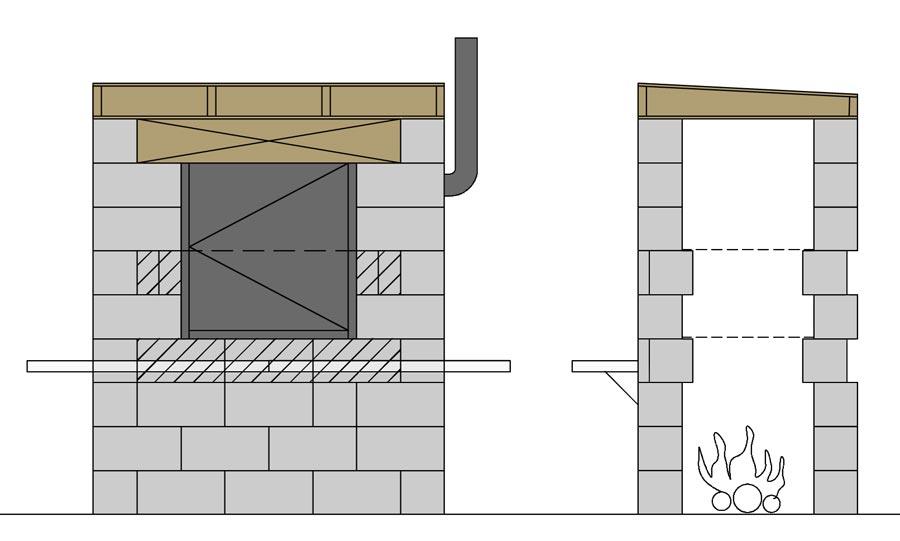

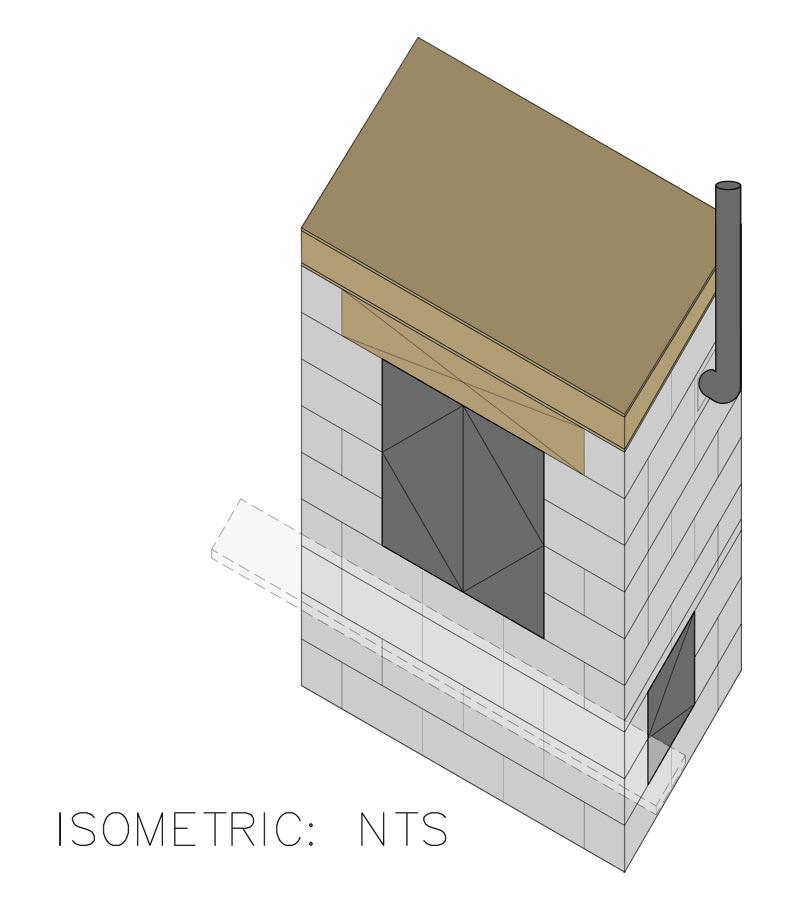

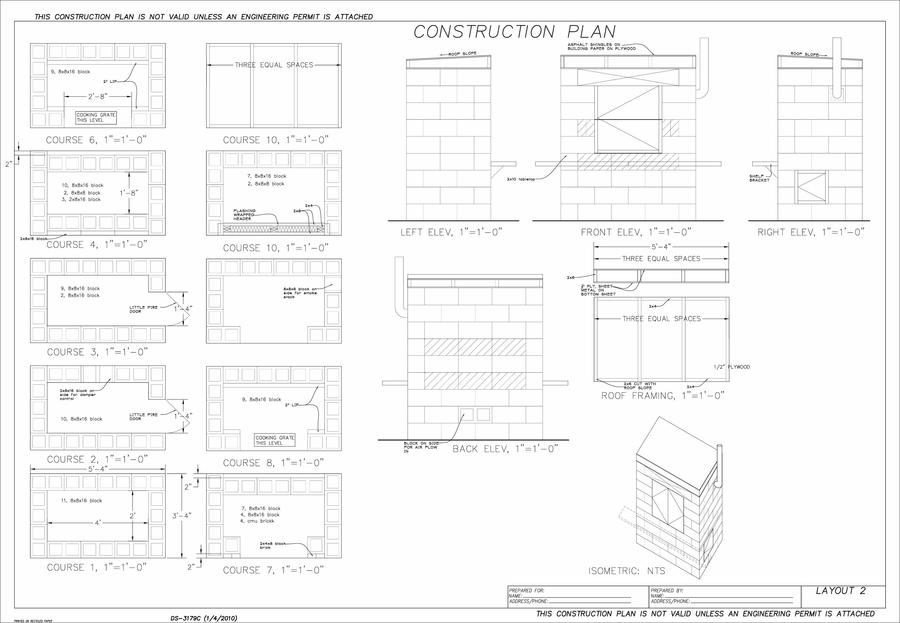

This is a front elevation and a section through the smoker. The dashed lines indicate the two cooking grates (expanded steel). Please note that these blocks are your standard 8x8x16

You can click the image for a larger view. The door on the side would be a door to access the fire. The front grey doors, would either be one door, or two half doors.

Materials.

Dry Fit 8x8x16 (and a few half blocks) concrete blocks. I would put un faced batt (pink panther) insulation in the cores of these blocks while stacking.

The dark grey doors would be some sort of metal- i am not sure how what I will use for doors yet- If its a re-used object I will paint it with high-heat grill paint.

The header above the access doors would be 2- 2x8's wrapped in flashing. The roof would be a small wood framed roof. The roof structure would sit on the top course of brick- It would be a layer of sheet metal, painted high heat, 1/2" plywood then the roof studs (insulation between) a layer of plywood and shingles on the top.

The cook surface would be expanded steel sheets, 2'x4' per level. Though I have not figured out where- I will have a water pan somewhere between the fire and the first cooking grate.

The light grey area infront of the smoker is a little shelf/workspace probably a 2x10 held up on two shelf brackets.

The exhaust pipe. 4" duct. I will probably buy a galvanized elbow, but paint it with high heat paint inside and out- the rest of the duct out, i will paint if needed. For any areas that I need to fill in, I will use some of the high heat spray foam. Lastly I found chimney sealant to fill any seams with inside.

Since its cold up here in Michigan I won't be starting this project any earlier than mid-late march. Preliminary pricing (not including the doors) is floating around $250 ish.

Thanks in advance for any assistance. And of course as it gets built- I will post photos.

oh and it will be siting on a driveway slab.

So I have been Hot Smoking, BBQ;) for about 2.5 Years now. I have outgrown my electric bullet smoker and my Smoke Hollow 4 in 1. I do a lot of browsing on this forum but haven't posted much. I had intentions on making one out of an old propane tank (as many do) but I have not the skills to do such. So I thought I would make one out of Concrete block. I come from an architectural background and have drawn it up in autocad and would like any feedback any members have. below are some images i generated and splashed a bit of color on in photoshop.

This is a front elevation and a section through the smoker. The dashed lines indicate the two cooking grates (expanded steel). Please note that these blocks are your standard 8x8x16

You can click the image for a larger view. The door on the side would be a door to access the fire. The front grey doors, would either be one door, or two half doors.

Materials.

Dry Fit 8x8x16 (and a few half blocks) concrete blocks. I would put un faced batt (pink panther) insulation in the cores of these blocks while stacking.

The dark grey doors would be some sort of metal- i am not sure how what I will use for doors yet- If its a re-used object I will paint it with high-heat grill paint.

The header above the access doors would be 2- 2x8's wrapped in flashing. The roof would be a small wood framed roof. The roof structure would sit on the top course of brick- It would be a layer of sheet metal, painted high heat, 1/2" plywood then the roof studs (insulation between) a layer of plywood and shingles on the top.

The cook surface would be expanded steel sheets, 2'x4' per level. Though I have not figured out where- I will have a water pan somewhere between the fire and the first cooking grate.

The light grey area infront of the smoker is a little shelf/workspace probably a 2x10 held up on two shelf brackets.

The exhaust pipe. 4" duct. I will probably buy a galvanized elbow, but paint it with high heat paint inside and out- the rest of the duct out, i will paint if needed. For any areas that I need to fill in, I will use some of the high heat spray foam. Lastly I found chimney sealant to fill any seams with inside.

Since its cold up here in Michigan I won't be starting this project any earlier than mid-late march. Preliminary pricing (not including the doors) is floating around $250 ish.

Thanks in advance for any assistance. And of course as it gets built- I will post photos.

oh and it will be siting on a driveway slab.