Hello

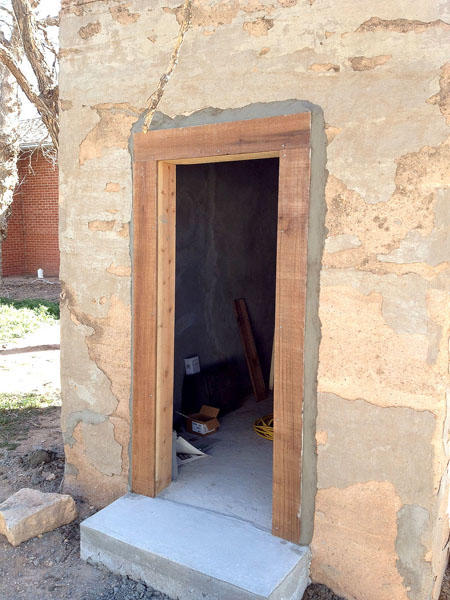

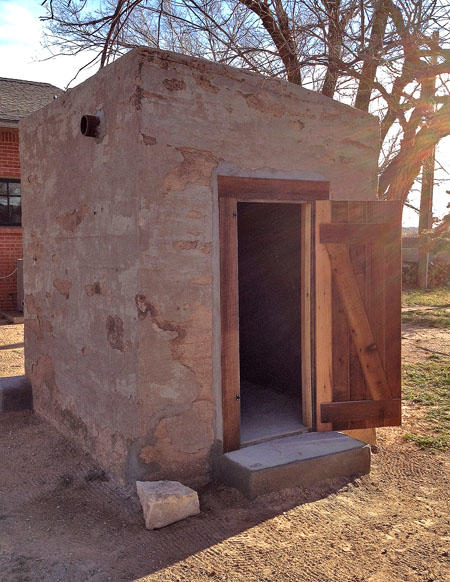

I have had it in the back of my mind to convert the below building into a smokehouse and have gotten the bug to get on with the project! I don't know the history on this architectural outcast but the walls are solid concrete. We don't use it for anything...it is just one giant brown recluse nest. It is 8ft. deep by 6ft. wide and has an 8ft ceiling. There was a cement slab in the bottom but it has cracked up as the ground has shifted. Aside from the door, there is no vent except for a 3" round hole in the base of the back wall. My only plans thus far are to patch the cracks in the outside, re-pour another cement floor over the existing slab, and re-frame and replace the door. From there, I am needing some suggestions. Initially, I am thinking I would use a propane burner inside the house to generate smoke/heat but I have several questions.

Is this space too big to reasonably/economically get hot enough to use as a hot smoker or will I have to use it only as a cold smoker?

Would it be feasible/beneficial to construct an external fire box and run the smoke/heat through the existing hole in the back?

Is it necessary to put a vent in the top, or could I put an adjustable vent in the new door? I am apprehensive about boring through the structure lest it start to implode.

Any help/suggestions are much appreciated!

Travis

I have had it in the back of my mind to convert the below building into a smokehouse and have gotten the bug to get on with the project! I don't know the history on this architectural outcast but the walls are solid concrete. We don't use it for anything...it is just one giant brown recluse nest. It is 8ft. deep by 6ft. wide and has an 8ft ceiling. There was a cement slab in the bottom but it has cracked up as the ground has shifted. Aside from the door, there is no vent except for a 3" round hole in the base of the back wall. My only plans thus far are to patch the cracks in the outside, re-pour another cement floor over the existing slab, and re-frame and replace the door. From there, I am needing some suggestions. Initially, I am thinking I would use a propane burner inside the house to generate smoke/heat but I have several questions.

Is this space too big to reasonably/economically get hot enough to use as a hot smoker or will I have to use it only as a cold smoker?

Would it be feasible/beneficial to construct an external fire box and run the smoke/heat through the existing hole in the back?

Is it necessary to put a vent in the top, or could I put an adjustable vent in the new door? I am apprehensive about boring through the structure lest it start to implode.

Any help/suggestions are much appreciated!

Travis