Reverse flow mini for camping and tailgating

- Thread starter jbssmokedmeats

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

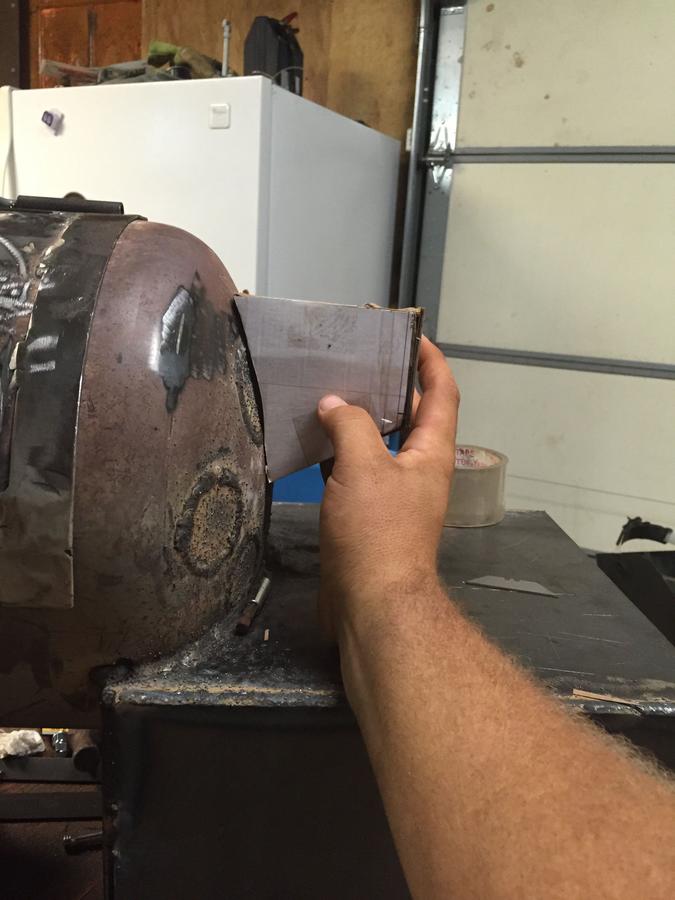

door seal is tacked on need to finish welding it grind the plugs from the valves and put hinges on and I will get the two matted

Got quite ablittlendone tonite on smoker

Have a ? On the plenum never really used a plenum like the looks of them don't understand the function of them but also at same time done want to screw up the draft it will have will this plenum work?? The angle and size of it is it sufficient to make this smoker work pictures are deceiving everything is level and square

Have a ? On the plenum never really used a plenum like the looks of them don't understand the function of them but also at same time done want to screw up the draft it will have will this plenum work?? The angle and size of it is it sufficient to make this smoker work pictures are deceiving everything is level and square

couple welds on the smoker see a lot of guys trying to use a flux core wire welder on here and there welds look like chicken pooooo I was fortunate to learn how to use a flux core a long time ago and this little $150 farm store 120v welder puts down a nice bead these pics don't do me and the welder justice damn phone takes crappy pics of you zoom in on the plenum pics you will see an nice flux core weld

Last edited:

Few more pics... I'll use my plasma to cut the pit out of the fire box from inside

Oh man what a cute little smoker.

What are you going to use to support it? how much does the whole thing weight so far?

What are you going to use to support it? how much does the whole thing weight so far?

I'll be putting a stand/Cart together under it this weekend more pics coming tomorrow night should have it smoking by Sunday if all goes well

Last nights progress got a lot of Welding to do now!

Last edited:

Been on a low.., it was a family time weekend, said the wife. so smoker got worked on Saturday morning for 2 hours of welding. no changes other than welded the plenum stack and 75% of rf plate.

smokejumper

Smoking Fanatic

Well it is getting really close have a rib cook off this weekend for the town celebration! It will be tested on its maiden voyage. Needs another vent test fired last night has good draft but I think I needs a little more air. I will take a pic of vents tomorrow need to make a latch for fb and paint oh and a front rack I'll be running my maverick on it so didn't put a therm. In cc door.

Well here is where it's at now seasoned it tonite had no issues hitting 350 degrees needs handles on vent cc door and fb door other than that it's done and paint of course. I'm cooking in a rib competition tomorrow with it wish me luck

smokejumper

Smoking Fanatic

Bingo Dave hopefully I won't need it

You don't need it.... It just makes your smoker operate better... Cleaner smoke..... better tasting food....

The tutorial we put together is a compilation of modifications folks have used to get the best smoker possible....

Here is my ribs from today first ever turn in box they turned out really well I was a little pressed for time and ended up short cooking them should stayed rapped for another 20 mins didn't have quite the right pull "little tight" ended up 3rd beat my boss and a kcbs level team

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 245

- Views

- 13K

- Replies

- 3

- Views

- 1K

- Replies

- 4

- Views

- 410

- Replies

- 0

- Views

- 742

Hot Threads

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 66

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 35

- Sausage

-

Colombian Chorizo

- Started by SmokinEdge

- Replies: 34

- Sausage

-

Took a stroll this afternoon

- Started by Buckeyedude

- Replies: 33

- Field and Stream

-

Featured Blackened Rockfish...

- Started by Gonna Smoke

- Replies: 33

- Fish