Since you have access to 220v where you want the smoker, I would use that. I would probably get 2 110v finned heating elements, each in the 1,500 watt range and wire one on each leg of the 220v circuit (in essence you are using the 220v service to deliver 2 110v circuits in the smoker). This gives you the option of using less wattage for a low temp smoke and having 3,000 watts available when you need it to deal with a large volume of air and meat. You could switch a single 220v 3,000 watt (or even larger) element no problem, but on lower temp smokes it may be harder to control as it's going to really want to heat up a higher wattage element fast. I'm sure a PID & SSR can probably hand it though but I know it can handle 3,000 watts split into the two 1,500 watt 110v element and give better control at lower temps. I just like having options. You could run both elements from the same PID triggering output with no issues. Just put a switch in the triggering output to one of the SSR's and you can turn it off to use a single element. Or put a switch in each triggering output line to the SSR's and you could alternate which element you used from one smoke to another to keep the element "aging" about the same (probably not really necessary though).

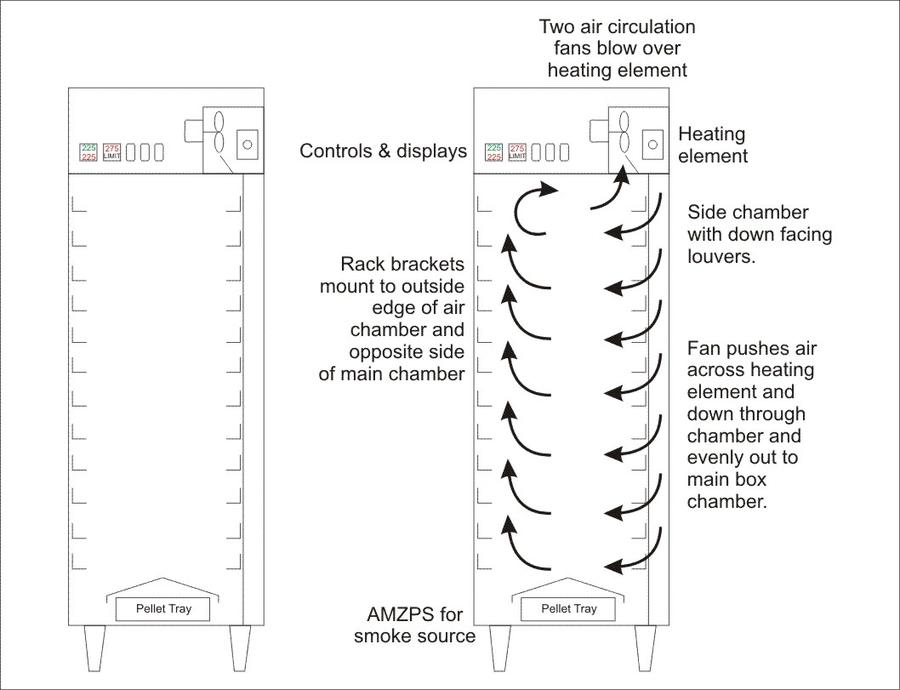

As to where to place the elements, I like in the upper part of the side chamber as again, no danger ever of a grease fire. Run some ducting at the top over to a heating element box and then use ducting to put the heat back into a slotted chamber along that side to evenly distribute it in the smoke chamber. Lots of options on where to put the fans, but I would have them blowing over the heating elements (although they do not have to be in the heating element box). You could use stainless flexible ducting (insulated with flexible rockwood or ceramic kiln insulation) and pretty much put the parts anywhere you want. Don't they make this stuff for lining chimney's in homes and connecting to wood stoves?