- Oct 11, 2017

- 7

- 1

Hi everyone,

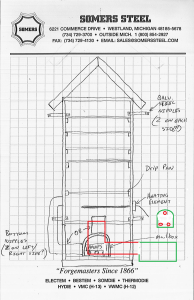

I have spent countless hours scouring these pages trying to come up with the right line of thought on how I want to go about building my smoke house. All I am looking for is some advice on if I am going down the right path, or if I am setting myself up for failure. First things first, I want to build a cold/hot smoker. I want to start with a 2x4 stick build that the outside sheathing will be T1-11 about 2'x2'x5'. My heat source will be an electric heating element (maybe multiple) controlled by a PLC with PID capabilities(engineer by trade and have a couple old ones sitting around... I know, probably overkill). Smoke will come from the AMNPS in a mailbox mod sitting under my box piped to one side of the smoker, and the air vent will be at the top on the opposite side. I would like to insulate the box and line it with something, but not sure what to do on that front.

Just want to get some opinions if I am starting out on the right foot, any advice would be greatly appreciated!

I have spent countless hours scouring these pages trying to come up with the right line of thought on how I want to go about building my smoke house. All I am looking for is some advice on if I am going down the right path, or if I am setting myself up for failure. First things first, I want to build a cold/hot smoker. I want to start with a 2x4 stick build that the outside sheathing will be T1-11 about 2'x2'x5'. My heat source will be an electric heating element (maybe multiple) controlled by a PLC with PID capabilities(engineer by trade and have a couple old ones sitting around... I know, probably overkill). Smoke will come from the AMNPS in a mailbox mod sitting under my box piped to one side of the smoker, and the air vent will be at the top on the opposite side. I would like to insulate the box and line it with something, but not sure what to do on that front.

Just want to get some opinions if I am starting out on the right foot, any advice would be greatly appreciated!