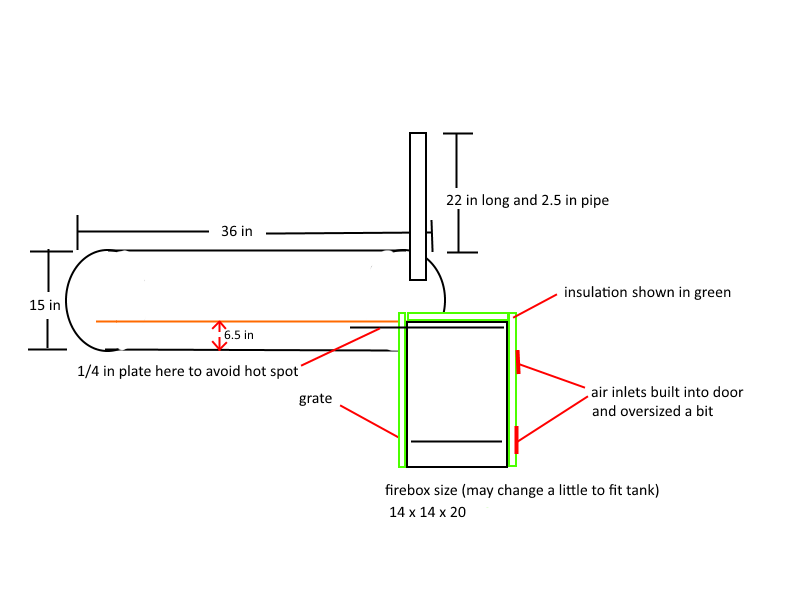

So I just purchased a 100 lb propane tank and will be building a patio RF

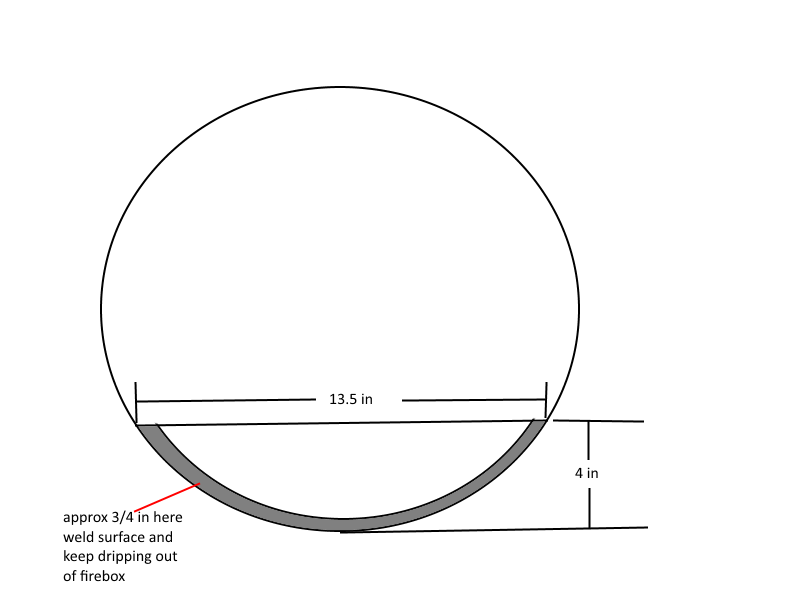

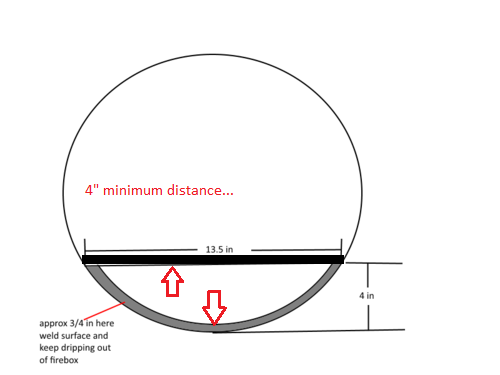

The tank comes out at about 27 gallon 15 in dia and approx 36in tall

I am calling the length at 36 in (from center of dome to center of dome) I think that will be close enough

have not started building yet need to burn the remaining gas in the tank

this one is a great example of what i am going to build, and will build it as nice as this one great job jwsimpleville

here is a pic of my last build, i love it but it is SOO big i just dont use it much and it now lives at a friends house

i would love to paint and finish this one just kinda lost interest in it, and my friend does not mind (he got a free smoker that i can use anytime). All jokes aside with all the leaks from not finishing the door seals the thing works great so i cant complain she just is not pretty the, new one will be

The tank comes out at about 27 gallon 15 in dia and approx 36in tall

I am calling the length at 36 in (from center of dome to center of dome) I think that will be close enough

have not started building yet need to burn the remaining gas in the tank

this one is a great example of what i am going to build, and will build it as nice as this one great job jwsimpleville

here is a pic of my last build, i love it but it is SOO big i just dont use it much and it now lives at a friends house

i would love to paint and finish this one just kinda lost interest in it, and my friend does not mind (he got a free smoker that i can use anytime). All jokes aside with all the leaks from not finishing the door seals the thing works great so i cant complain she just is not pretty the, new one will be

![20150104_185322[1].jpg](/media/20150104_185322-1-jpg.364827/full?d=1507232749)

![20150104_203848[1].jpg](/media/20150104_203848-1-jpg.364830/full?d=1507232749)

![20150104_203859[1].jpg](/media/20150104_203859-1-jpg.364831/full?d=1507232749)

![20150104_203930[1].jpg](/media/20150104_203930-1-jpg.364833/full?d=1507232749)

![20150104_185322[1].jpg](/media/20150104_185322-1-jpg.364841/full?d=1507232749)

![20150104_204125[1].jpg](/media/20150104_204125-1-jpg.364846/full?d=1507232749)

![20150112_195612[1].jpg](/media/20150112_195612-1-jpg.366586/full?d=1507232864)