- Mar 2, 2023

- 36

- 19

After nearly 100 sessions on the Oklahoma Joes Bandera Vertical Offset, I have two recommended modifications that made a huge difference in my cooks.

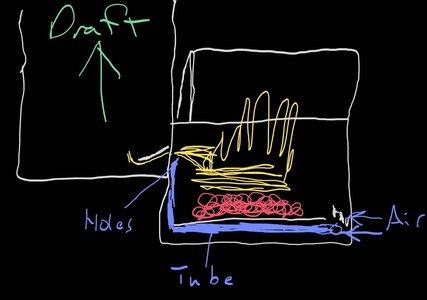

1. Instead of using the provided round water pan, I would recommend purchasing a 2/3rd size steam pan. As shown in the provided picture, it fits perfectly on the provided water pan bracket and when placed centered (from front to back), the result is very even temps with no hot spots in the entire smoking chamber from side to side or from top to bottom. Any excess draft that may draw the fire into the vertical smoking chamber is diffused under the water pan and is evenly distributed along the sides of the smoker.

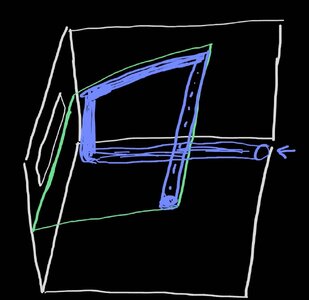

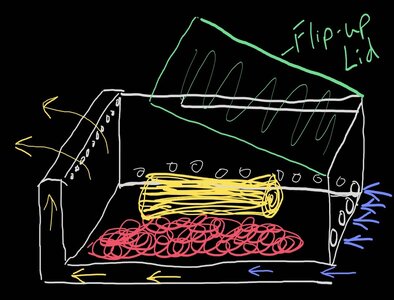

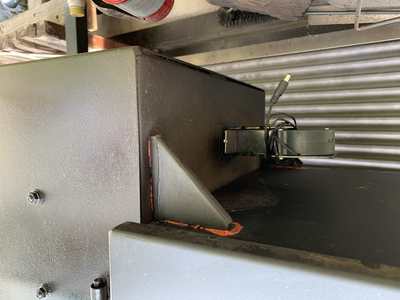

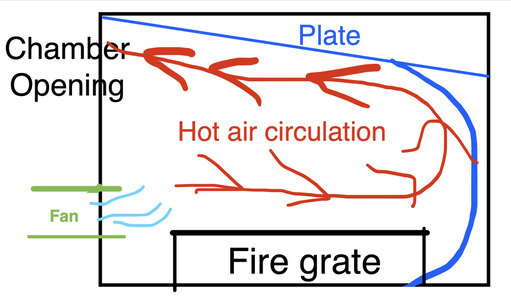

2. Since a lot of heat is lost due to the lid for the firebox, I chose to employ a metal plate. I placed a handle on one side so that it is easy to lift up. As a bonus, the existing lid will hold the plate up while working in the firebox. This single mod vastly improved the airflow and also provided an easy way to preheat smaller splits before they go into the firebox or add an additional surface as a griddle or for pots/pans.

Last, I would highly recommend the use of expanded metal for a charcoal basket. It allows me to focus the fire and burn just wood splits for the duration of the cook (after starting with a half chimney of lump charcoal). It also allows me to prop up the small wood splits on the left side, directly over the coals, and run a clean fire. In addition, if you are running a low and slow fire, you can put a small split on the right, near the intake, to preheat for a cleaner fire when moved into the fire on the left.

I hope that this is helpful. Please let me know if you have any questions.

1. Instead of using the provided round water pan, I would recommend purchasing a 2/3rd size steam pan. As shown in the provided picture, it fits perfectly on the provided water pan bracket and when placed centered (from front to back), the result is very even temps with no hot spots in the entire smoking chamber from side to side or from top to bottom. Any excess draft that may draw the fire into the vertical smoking chamber is diffused under the water pan and is evenly distributed along the sides of the smoker.

2. Since a lot of heat is lost due to the lid for the firebox, I chose to employ a metal plate. I placed a handle on one side so that it is easy to lift up. As a bonus, the existing lid will hold the plate up while working in the firebox. This single mod vastly improved the airflow and also provided an easy way to preheat smaller splits before they go into the firebox or add an additional surface as a griddle or for pots/pans.

Last, I would highly recommend the use of expanded metal for a charcoal basket. It allows me to focus the fire and burn just wood splits for the duration of the cook (after starting with a half chimney of lump charcoal). It also allows me to prop up the small wood splits on the left side, directly over the coals, and run a clean fire. In addition, if you are running a low and slow fire, you can put a small split on the right, near the intake, to preheat for a cleaner fire when moved into the fire on the left.

I hope that this is helpful. Please let me know if you have any questions.

Last edited by a moderator: