Traulsen Commercial Refrigerator build

- Thread starter nevrsummr

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Darned if I know.... I do know I wish I had it on my smokers.... Maybe a N-O closes on overtemp situation.. I'm no electrician but at times I have an idea what I would want...

Ok Dave, I slept on it and have an idea. There are 2 relay outputs on the SMD100, a person could program one to come on at start and go off at say 300, then you could use that as a secondary control for your heat element. It's only rated for 10 amps, but an ice cube relay would fix that. You could pull an extra set of contacts on the ice cube relay for alarm.

Any math gurus out there who could tell me what the volume on my chimney (2x4) would be in comparison to a 3" pipe?

2x4=8" = 6.2 sq. in. hydraulic volume or close...

3" = 7" sq. in. hydraulic volume...

3" = 7" sq. in. hydraulic volume...

Last edited:

Thankyou! Probably a stupid question, but will the 3" move more than "8" or will the 3" just move more than "7"? I was going for 3" volume but that is what was available in the scrap bin. And I think it turned out great. I was able to fit it into the top instead of my original plan of going out the back. This saves me about 4 inches of head room for hanging sausage. I built a condensate trap into the back so hopefully there won't be any problems with dripping.

Also, I cut 2-2" holes into the top of the smoker and into the chimney. Is that enough for 2x4 or is it choking it down?

Also, I cut 2-2" holes into the top of the smoker and into the chimney. Is that enough for 2x4 or is it choking it down?

2x4=8" = 6.2 sq. in. hydraulic volume or close...

3" = 7" sq. in. hydraulic volume...

Gotchya. Thanks so much Dave

was requested to fix a water heater today, the problem... a thermal cutout. This would be another option in preventing flare ups. Which, btw I had my first one yesterday. I was outside shoveling the deck and started smelling plastic burning. Ran to the smoker and the heat element was basically on fire, I think some wiring underneath must be burnt (plastic smell) I had already pulled the turkey, so just the potatoes were affected. The cause was my fault, I put the chips on the heater element instead of the smoker element. ( smoker is on a rheostat)Darned if I know.... I do know I wish I had it on my smokers.... Maybe a N-O closes on overtemp situation.. I'm no electrician but at times I have an idea what I would want...

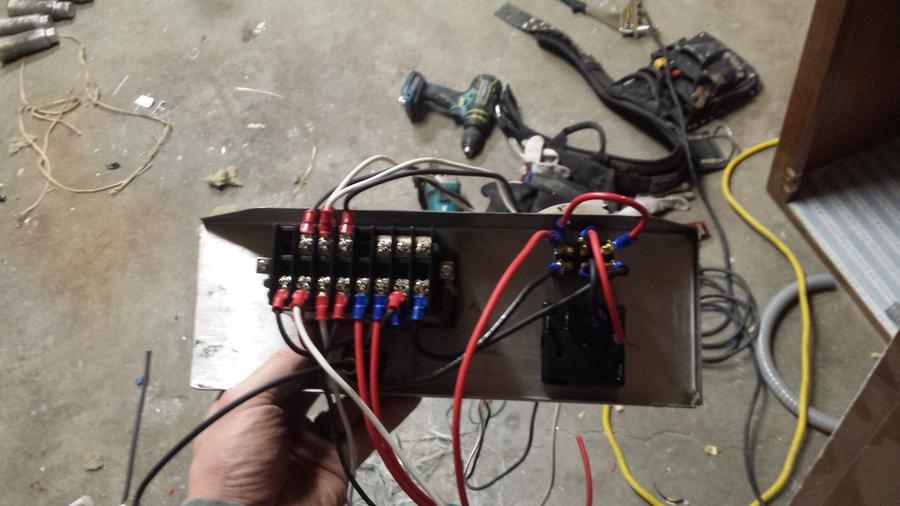

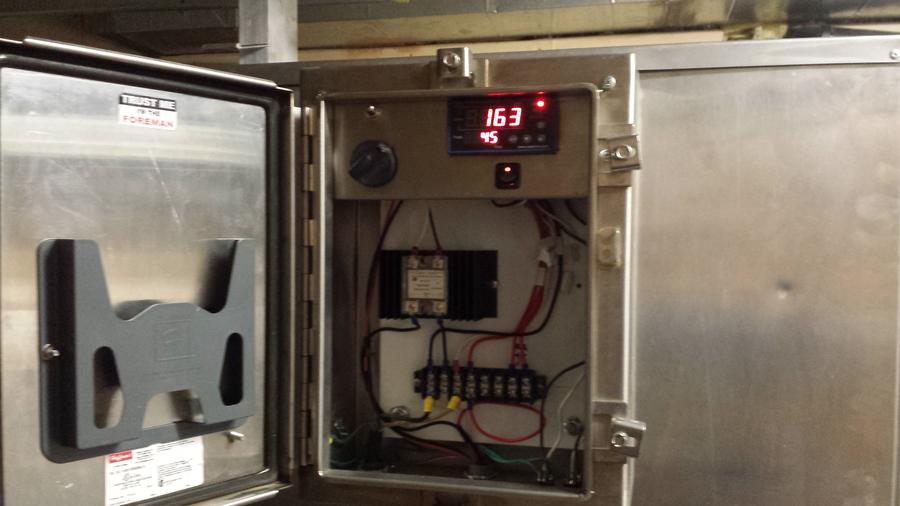

well, she's ready to fire. Cleaned up nice I would say.

managed to do a burn in last night. Ramped it up slowly to watch for problems. Took it to 250 for about 4 hours. This will be the max temp on my smoker so I didn't want to risk taking it higher. The original door seals seemed to hold up fine at 250, so hopefully that will last. Overall I was very pleased with the performance and I am starting to make sense of the programming.

It is so cool to be able to set a temp and know it will be accurately reached and held within 5 degrees. Even low temps!

The smoker was in my garage (not recommended for burn in) and the garage temp was about 43 degrees. Much colder outside. At 250 the outside of the smoker was cold to the touch, the roof and floor were not warm but not cold. Tepid I would say.

I did have 1 scare with the SMD100 control. When I first turned it on, it read an error code of "H".it also smelled like it was burning up. I did some reading and found that it's set up from the factory for K type thermocouples. Went into code 155 and changed that for the RTD probes that I am using, and it worked fine after that. As for the smell, must have been a first time use thing.

It is so cool to be able to set a temp and know it will be accurately reached and held within 5 degrees. Even low temps!

The smoker was in my garage (not recommended for burn in) and the garage temp was about 43 degrees. Much colder outside. At 250 the outside of the smoker was cold to the touch, the roof and floor were not warm but not cold. Tepid I would say.

I did have 1 scare with the SMD100 control. When I first turned it on, it read an error code of "H".it also smelled like it was burning up. I did some reading and found that it's set up from the factory for K type thermocouples. Went into code 155 and changed that for the RTD probes that I am using, and it worked fine after that. As for the smell, must have been a first time use thing.

Forgot to mention, about 2 hours after I turned it off I went to check on it. When I opened the door it was very warm inside. I turned it on to check temp and it was still 143* probably 153 before I opened the door. That's after 2 hours of sitting in a 43* garage. So I think it's going to be very efficient.

madman mike

Smoking Fanatic

- Feb 6, 2014

- 314

- 18

1/2" or 3/4" wood dowel works great, or get some 20g bent into a 90degree smoking sticks. they only need to be 3/4"x3/4" x width of smokehouse so the rest on the shelving racks.

Well, I wish I could say it's up and running great, but having problems with off gassing from the insulation. Now I don't trust the insulation so it has to go. Which means dismantling the whole project. Wish I used screws instead of rivets. Pretty bummed right now, haven't touched it in days.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 3

- Views

- 705

- Replies

- 1

- Views

- 1K

- Replies

- 25

- Views

- 3K

Hot Threads

-

Our Second piece of Heaven, Little piece on the Atlantic Ocean

- Started by DRKsmoking

- Replies: 55

- General Discussion

-

How Do I Get Rid of These Armadillos?!!

- Started by seenred

- Replies: 39

- Blowing Smoke Around the Smoker.

-

Non fat dried milk

- Started by hog warden

- Replies: 37

- Sausage

-

Getting to the bottom of what happens to cure in smoked sausage

- Started by hog warden

- Replies: 31

- Food Safety

-

Featured A couple thick strips please!