I would double check your smoke stack calculations in the spreadsheet...it appears you are using (perimeter * height) for the volume instead of area...that is about as far as I got...unfortunately I have to get some work done today...will peck at it later here and there....

Standard Reverse Flow Smoker Calculator... by DaveOmak and others... Ready to use.. rev5.. 6/19/15.

- Thread starter daveomak

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

You can edit the data and input by just turning off the protection...click on file and then the Protect Workbook locking tab...there is no password.

I would double check your smoke stack calculations in the spreadsheet...it appears you are using (perimeter * height) for the volume instead of area...that is about as far as I got...unfortunately I have to get some work done today...will peck at it later here and there....

Are you referring to post #1, my numbers, or Gary's calculator.....

Dave

novasbc

Smoke Blower

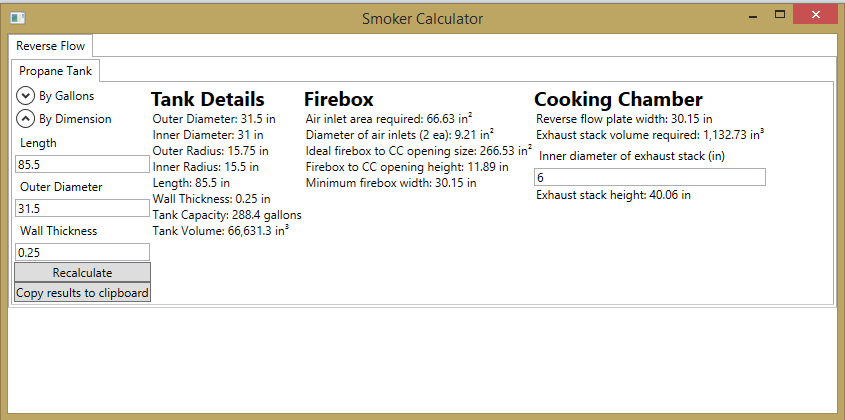

I wrote a calculator that to me was easier to use. I did this for two reasons, calculating many options on paper was annoying, and I understand things better if I can write a program out of it.

You can enter the tank volume if you don't have measurements (I.E. 250 gallons), but you can't calculate the firebox opening from this. You have to actually enter the length and diameter of the tank. It asks you for the thickness of the tank walls to calculate the inner diameter, used in calculating the firebox volume.

For most calculations, I use the original post by DaveOmak (Edited by DaveOmak - 11/17/14 at 10:35pm). I didn't like having to guess at the height of the firebox opening, though. I spent hours trying to figure out how to calculate the height given the area and the radius, but I failed. Maybe I can't do it, or I just didn't try hard enough, math wasn't my absolute strongest course ever.

Regardless, I cheated, and since computers are pretty fast, I brute forced the thing. I start from a theoretical opening height of 0.001, and in increments of 0.001, I calculate the area of the theoretical opening. We already know the ideal opening size in square inches from DaveOmak's calculations, so I keep incrementing until I go over the ideal. Then, I compare the corresponding area that was a little shy of the ideal opening area, and the area that was just slightly bigger than the ideal opening area. Whichever one is closer, I use that opening height. Perhaps I should just pick the height that just barely puts it over the ideal?

I used the following formula in calculating the area based on the radius and theoretical opening height:

Math.Pow(radius, 2) * Math.Acos((radius - segmentHeight) / radius) - (radius - segmentHeight) * Math.Sqrt((2 * radius * segmentHeight) - Math.Pow(segmentHeight, 2)). It seems to match up with the calculator given in the thread.

You can see the results below I get for my propane tank:

If you click the button to copy to clipboard, I get this:

The tool currently runs on Windows, with the only requirement having .NET 4.5.1 (http://www.microsoft.com/en-us/download/details.aspx?id=40773)

If there is any interest, I can post the program. Perhaps I'll put it on github or codeproject as well.

Things I intend to do in the not too distant future:

Mark

You can enter the tank volume if you don't have measurements (I.E. 250 gallons), but you can't calculate the firebox opening from this. You have to actually enter the length and diameter of the tank. It asks you for the thickness of the tank walls to calculate the inner diameter, used in calculating the firebox volume.

For most calculations, I use the original post by DaveOmak (Edited by DaveOmak - 11/17/14 at 10:35pm). I didn't like having to guess at the height of the firebox opening, though. I spent hours trying to figure out how to calculate the height given the area and the radius, but I failed. Maybe I can't do it, or I just didn't try hard enough, math wasn't my absolute strongest course ever.

Regardless, I cheated, and since computers are pretty fast, I brute forced the thing. I start from a theoretical opening height of 0.001, and in increments of 0.001, I calculate the area of the theoretical opening. We already know the ideal opening size in square inches from DaveOmak's calculations, so I keep incrementing until I go over the ideal. Then, I compare the corresponding area that was a little shy of the ideal opening area, and the area that was just slightly bigger than the ideal opening area. Whichever one is closer, I use that opening height. Perhaps I should just pick the height that just barely puts it over the ideal?

I used the following formula in calculating the area based on the radius and theoretical opening height:

Math.Pow(radius, 2) * Math.Acos((radius - segmentHeight) / radius) - (radius - segmentHeight) * Math.Sqrt((2 * radius * segmentHeight) - Math.Pow(segmentHeight, 2)). It seems to match up with the calculator given in the thread.

You can see the results below I get for my propane tank:

If you click the button to copy to clipboard, I get this:

The tool currently runs on Windows, with the only requirement having .NET 4.5.1 (http://www.microsoft.com/en-us/download/details.aspx?id=40773)

If there is any interest, I can post the program. Perhaps I'll put it on github or codeproject as well.

Things I intend to do in the not too distant future:

- Allow for one to use two exhaust stacks, and calculate the height required based on inner diameter

- Calculate the diameter of the firebox inlet areas, assuming you put two circular inlets, one at the top, one at the bottom.

- Allow for square firebox inlets

- Allow for square cooking chamber exhaust stacks.

Mark

novasbc

Smoke Blower

I forgot, the next item on the list is the firebox dimensions themselves. Wife will kill me if I don't get off the computer.

Great job..... It was difficult enough for me to put my slide rule away and start using a Frieden mechanical calculator and then an electronic calculator.... figuring out stuff, like you did, I don't think I'm up for it....... Good thing you young guys are around here.....

Dave

Dave

novasbc

Smoke Blower

I made various updates, including RF plate width, and minimum firebox width (since they are the same).

Maybe I'm missing it, I saw it on the Feldon calculator, which calculated the Firebox volume, is that part of this equation? I'd like to calculate the total volume required for the firebox as part of my tool.

It seems from what I understand, that you want the firebox to be at least as big as a certain amount, for calculations in that Feldon calculator, but then you can increase it later. I'll do some more research into how they calculate that to see if I can integrate it into my program.

For those who have .NET 4.5.1, I am attaching the first version of my smoker calculator.

Maybe I'm missing it, I saw it on the Feldon calculator, which calculated the Firebox volume, is that part of this equation? I'd like to calculate the total volume required for the firebox as part of my tool.

It seems from what I understand, that you want the firebox to be at least as big as a certain amount, for calculations in that Feldon calculator, but then you can increase it later. I'll do some more research into how they calculate that to see if I can integrate it into my program.

For those who have .NET 4.5.1, I am attaching the first version of my smoker calculator.

Last edited:

novasbc

Smoke Blower

Had yet a little more time and added firebox calculations, assuming that the firebox should be 1/3 the volume. It lets you set the height, width, and depth, and tells you if you meet the minimum requirements.

Last edited:

novasbc

Smoke Blower

How much of an increase or decrease are you talking about, and of which number? I assume raising or lowering the value of 0.7854 you use initially, to calculate the volume in cubic inches?

How much of an increase or decrease are you talking about, and of which number? I assume raising or lowering the value of 0.7854 you use initially, to calculate the volume in cubic inches?

If you back calculate, you will know where the 0.7854 number came from.... It can not be changed....

novasbc

Smoke Blower

Yeah, apparently I shouldn't be doing math at 1:00 in the morning after driving. It is patently obvious in the morning that it is the same as doing π*r²*h, but since you are using the diameter instead of the radius, it would end up with quadruple the value it should be, hence dividing PI / 4. I just couldn't come to that conclusion after being up for 20+ hours already!If you back calculate, you will know where the 0.7854 number came from.... It can not be changed....

That however works accurately if you are calculating the volume of the pipe area alone, with I guess the multiplication of 0.004 (dividing by 250) trying to take into account for the end caps, hence why you say altering it depending on whether (it is short/fat or longer/skinnier) the end caps are spherical or elliptical?

Should I in reality offer the ability to use the calculations from the Propane Tank Dimensional and Volume Data Calculator to determine the volume, and then multiply by a value that works no matter what the shape of the end-caps are (or if it is flat, and not a propane tank)? It requires you to measure the length of the end-caps, and specify whether they are elliptical, spherical, or flat (I think we are no longer talking a propane tank if they are flat).

I'm still not quite sure how much of an increase or decrease one is looking for, though, as an ideal.

Try calculating the "surface area vs volume" under the RF plate of a short fat tank and a long skinny tank of the same gallons.....

ie. 250 gallon tank 96" long and a 250 gallon tank 48" long.... Don't worry about the convex ends... this ain't rocket science... You will see where loss due to friction "might" have an effect on air flow...

ie. 250 gallon tank 96" long and a 250 gallon tank 48" long.... Don't worry about the convex ends... this ain't rocket science... You will see where loss due to friction "might" have an effect on air flow...

novasbc

Smoke Blower

So, the point of the calculation is to get a value for the size of the opening from the firebox all the way until it gets into the cooking area. This size should remain the same throughout, too small, and it gets restricted, and too big, it likely causes currents.Try calculating the "surface area vs volume" under the RF plate of a short fat tank and a long skinny tank of the same gallons.....

ie. 250 gallon tank 96" long and a 250 gallon tank 48" long.... Don't worry about the convex ends... this ain't rocket science... You will see where loss due to friction "might" have an effect on air flow...

I can see that a longer tank would have more surface area of the RF plate to move across, so you might want to increase that opening by some degree to compensate. I just don't know "how much", are we talking about increasing it 0.1%, 1%, or 10%? I'm still trying to figure out how to calculate what you suggest, but, since I haven't figured out how to properly calculate the length of the RF plate, I can't figure out the surface area of it yet.

Dual purpose, I'd like to make sure the calculator makes sense, since it's based on the exact formulas in the first post only, as well as I'd like to make a trip to the metal yard today to pick up the materials for the firebox, and perhaps the RF plate. They'll be closed tomorrow :).

I have no feel for how much fudge one has in these calculations. From my initial understanding, you needed to be pretty spot-on, or screw it all up. I'd prefer not to lead other people wrong, or screw mine up real bad either!

My next steps are to include a dynamic illustration that shows the tank, the firebox, the reverse flow plate, and let you see the suggested dimensions overlaid, for the visual people (like me).

Last edited:

lendecatural

Smoking Fanatic

You will not need to increase it for a long narrow tank from the calculations Dave posted above. The numbers will be fine without modification and all will work quite well. Departures in excess of 15% will have an effect, otherwise, as designed, Dave's formula is optimum. The type of fuel you use and how you manage the vents during a cook have a more drastic effect on the smoke than does a change of 5% from Dave's optimum design numbers. Good luck and keep us posted!

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 218

- Views

- 12K

- Replies

- 15

- Views

- 4K

- Replies

- 6

- Views

- 2K

- Replies

- 44

- Views

- 8K

- Replies

- 140

- Views

- 20K

Hot Threads

-

Our Second piece of Heaven, Little piece on the Atlantic Ocean

- Started by DRKsmoking

- Replies: 55

- General Discussion

-

Non fat dried milk

- Started by hog warden

- Replies: 37

- Sausage

-

How Do I Get Rid of These Armadillos?!!

- Started by seenred

- Replies: 36

- Blowing Smoke Around the Smoker.

-

Getting to the bottom of what happens to cure in smoked sausage

- Started by hog warden

- Replies: 31

- Food Safety