- Apr 16, 2016

- 10

- 11

Hi all - Just wanted to throw my numbers out there and see if I am on the right track. I am building my smoker out of a 30 gallon compressor tank. So far I have the wheels and top plate removed so I wanted to check with ya'll before I started cutting any thing else. Any assistance would be appreciated, Thanx Bob

Smoker Numbers

Wednesday, May 04, 2016

11:20 AM

Calculations for a standard design, reverse flow smoker..

Volume of the Cook Chamber.... Use the Inside Diameter of the tank...

Diameter X Diameter X 0.7854 X Length = Volume in cubic inches / 231 = Volume in gallons

16 x 16 x 0.7854 x 36 = 7,238.2464 / 231 = 31.3344

Volume in cubic inches X 0.004 = FB/CC opening in square inches

7,238 x 0.004 = 28.952

Volume in cubic inches X 0.004 = Area under the RF plate in square inches

7,238 x 0.004 = 28.952

Volume in cubic inches X 0.004 = Area required at the end of the RF plate in square inches

7,238 x 0.004 = 28.952

Volume in cubic inches X 0.33 = minimum volume of the Fire Box

7,238 x 0.33 = 2,388.54

The above areas are necessary for great air/heat/smoke flow.... using less may cause an overheated FB.... Narrow / Long CC may require an increase in those numbers due to increased surface area friction to volume... Wide/Fat Short CC may use smaller numbers due to reduced surface area friction to volume...

Volume in cubic inches X 0.001 = FB air inlets in square inches…

7,238 x 0.001 = 7.238

Recommended upper and lower air inlets... Upper air inlet directly across from the FB/CC opening to facilitate moving heat from the FB to the CC, and insuring good air flow through the CC.. The lower air inlet should be situated at or below the fuel grate.... The two air inlets can share the designated square inches of opening.... approx. 20% upper and 80% lower...

Volume in cubic inches X 0.022 = Exhaust Stack Volume in cubic inches, above the CC.... (ESV) .. (The increase in volume ~30% shows a dramatic improvement in equalized temperatures across the cooking surface... edit 6/19/15 )

7,238 x 0.022 = 159.236

Exhaust Calculation..

ESV in cubic inches / 0.7854 X Stack Diameter X Stack Diameter = Stack Length in inches (36" +/-)

0.7854 X 4 X 4 = 12.5664

159.236 / 12.5 = 12.7389

0.7854 X 3 X 3 = 7.0686

159.236 / 7 = 22.748

0.7854 X 2.75 X 2.75 = 5.9396

159.236 / 5.9 = 26.9892

0.7854 X 2.5 X 2.5 = 4.9088

159.236 / 4.9 = 32.4971

0.7854 X 2 X 2 = 3.1416

159.236 / 3.1 = 51.3665

The [Segment Area] box is what you area going to compare with the FB/CC opening in square inches...

Volume in cubic inches X 0.004 = FB/CC opening in square inches

7,238 x 0.004 = 28.952

If the FB/CC opening number is smaller, change the number in the Segment Height ED box to 5.... continue changing that number until the [Segment Area] matches the FB/CC number.....

Now look at the colored circles above.... Segment height ED is how tall the green area is and corresponds to the area to be cut out.....

Segment height ED = 3.250

Also, [Chord AB] corresponds to the width of the RF plate... NOTE... for ease in fitment, the FB should be at least as wide as the RF plate..

Chord AB (RF Plate) = 12.87

Smoker Numbers

Wednesday, May 04, 2016

11:20 AM

Calculations for a standard design, reverse flow smoker..

Volume of the Cook Chamber.... Use the Inside Diameter of the tank...

Diameter X Diameter X 0.7854 X Length = Volume in cubic inches / 231 = Volume in gallons

16 x 16 x 0.7854 x 36 = 7,238.2464 / 231 = 31.3344

Volume in cubic inches X 0.004 = FB/CC opening in square inches

7,238 x 0.004 = 28.952

Volume in cubic inches X 0.004 = Area under the RF plate in square inches

7,238 x 0.004 = 28.952

Volume in cubic inches X 0.004 = Area required at the end of the RF plate in square inches

7,238 x 0.004 = 28.952

Volume in cubic inches X 0.33 = minimum volume of the Fire Box

7,238 x 0.33 = 2,388.54

The above areas are necessary for great air/heat/smoke flow.... using less may cause an overheated FB.... Narrow / Long CC may require an increase in those numbers due to increased surface area friction to volume... Wide/Fat Short CC may use smaller numbers due to reduced surface area friction to volume...

Volume in cubic inches X 0.001 = FB air inlets in square inches…

7,238 x 0.001 = 7.238

Recommended upper and lower air inlets... Upper air inlet directly across from the FB/CC opening to facilitate moving heat from the FB to the CC, and insuring good air flow through the CC.. The lower air inlet should be situated at or below the fuel grate.... The two air inlets can share the designated square inches of opening.... approx. 20% upper and 80% lower...

Volume in cubic inches X 0.022 = Exhaust Stack Volume in cubic inches, above the CC.... (ESV) .. (The increase in volume ~30% shows a dramatic improvement in equalized temperatures across the cooking surface... edit 6/19/15 )

7,238 x 0.022 = 159.236

Exhaust Calculation..

ESV in cubic inches / 0.7854 X Stack Diameter X Stack Diameter = Stack Length in inches (36" +/-)

0.7854 X 4 X 4 = 12.5664

159.236 / 12.5 = 12.7389

0.7854 X 3 X 3 = 7.0686

159.236 / 7 = 22.748

0.7854 X 2.75 X 2.75 = 5.9396

159.236 / 5.9 = 26.9892

0.7854 X 2.5 X 2.5 = 4.9088

159.236 / 4.9 = 32.4971

0.7854 X 2 X 2 = 3.1416

159.236 / 3.1 = 51.3665

The [Segment Area] box is what you area going to compare with the FB/CC opening in square inches...

Volume in cubic inches X 0.004 = FB/CC opening in square inches

7,238 x 0.004 = 28.952

If the FB/CC opening number is smaller, change the number in the Segment Height ED box to 5.... continue changing that number until the [Segment Area] matches the FB/CC number.....

Now look at the colored circles above.... Segment height ED is how tall the green area is and corresponds to the area to be cut out.....

Segment height ED = 3.250

Also, [Chord AB] corresponds to the width of the RF plate... NOTE... for ease in fitment, the FB should be at least as wide as the RF plate..

Chord AB (RF Plate) = 12.87

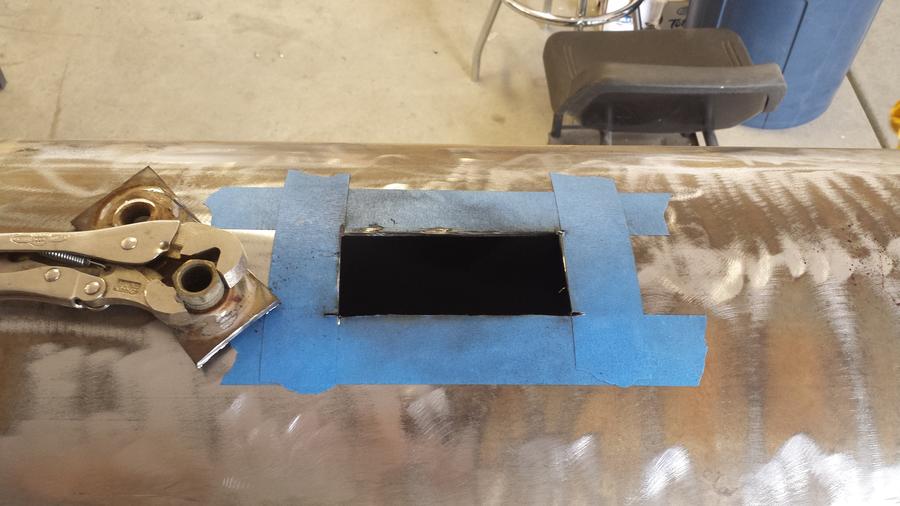

![20160522_100000[1].jpg](/media/20160522_100000-1-jpg.471047/full?d=1507240396)

![20160522_100056[1].jpg](/media/20160522_100056-1-jpg.471048/full?d=1507240396)

![20160522_153048[1].jpg](/media/20160522_153048-1-jpg.471050/full?d=1507240396)

![20160522_153108[1].jpg](/media/20160522_153108-1-jpg.471051/full?d=1507240396)