I've been wanting to build a curing cabinet for a few years and have been reviewing as many builds as I could find online.

This thread by xutfuzzy was very informative and inspirational: http://www.smokingmeatforums.com/t/135332/i-did-it-i-built-my-curing-chamber-massive-amounts-of-build-view

I finally broke down and bought a $50 craigslist fridge.

I'll post pics of the build in another thread. Meanwhile, I have wiring questions that I hope someone will be able to help with.

For the thermostatic controller, I bought the STC-1000. It's wired per other build examples.

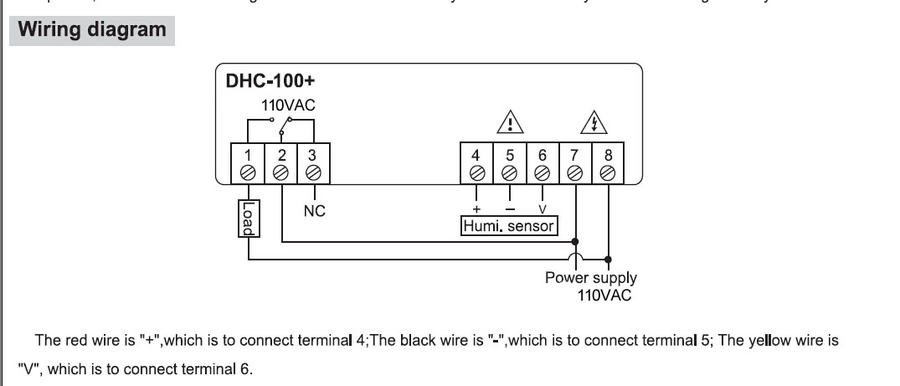

For the hygrostatic controllers, I bought a pair of DHC-100's. The terminal layout I was expecting was this:

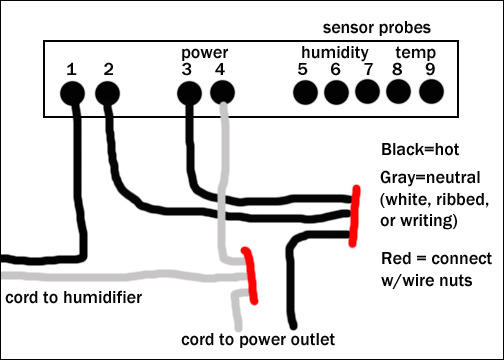

However, when I went to wire it up, what I found was this layout:

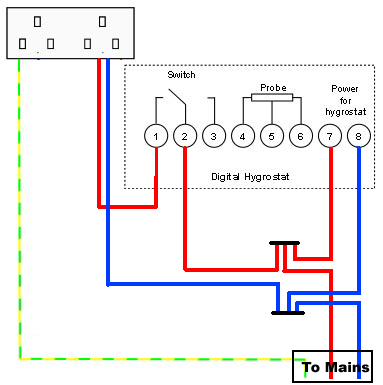

Do the wiring paths I've drawn here look right?

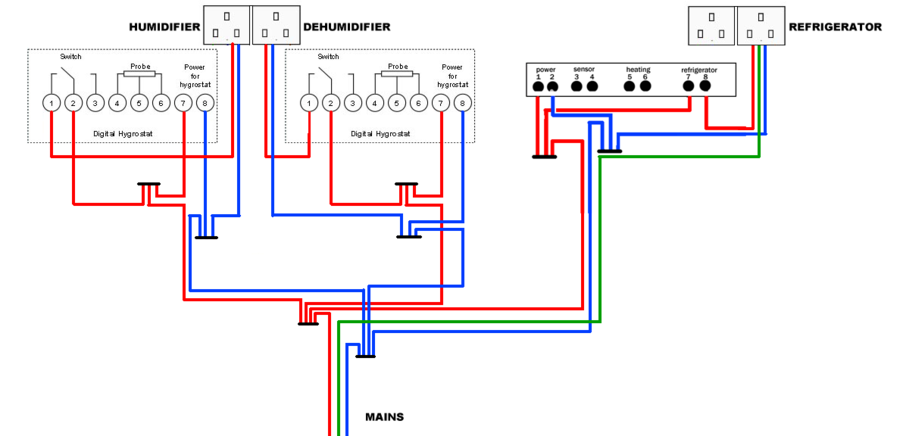

And, to further complicate it, I'm running the STC-1000 and two DHC-100s off of a single mains line, so my proposed wiring layout looks like this:

The URL for a larger view is https://41.media.tumblr.com/9a8c971cccc236277463c1eb04234a82/tumblr_o5ueoeAhy91slgto9o2_1280.png

Before I power all of this up, I want to make sure I won't be destroying controllers or turning the fridge into a giant bug zapper.

Does anyone see problems with this layout?

Thanks!

This thread by xutfuzzy was very informative and inspirational: http://www.smokingmeatforums.com/t/135332/i-did-it-i-built-my-curing-chamber-massive-amounts-of-build-view

I finally broke down and bought a $50 craigslist fridge.

I'll post pics of the build in another thread. Meanwhile, I have wiring questions that I hope someone will be able to help with.

For the thermostatic controller, I bought the STC-1000. It's wired per other build examples.

For the hygrostatic controllers, I bought a pair of DHC-100's. The terminal layout I was expecting was this:

However, when I went to wire it up, what I found was this layout:

Do the wiring paths I've drawn here look right?

And, to further complicate it, I'm running the STC-1000 and two DHC-100s off of a single mains line, so my proposed wiring layout looks like this:

The URL for a larger view is https://41.media.tumblr.com/9a8c971cccc236277463c1eb04234a82/tumblr_o5ueoeAhy91slgto9o2_1280.png

Before I power all of this up, I want to make sure I won't be destroying controllers or turning the fridge into a giant bug zapper.

Does anyone see problems with this layout?

Thanks!

Last edited: