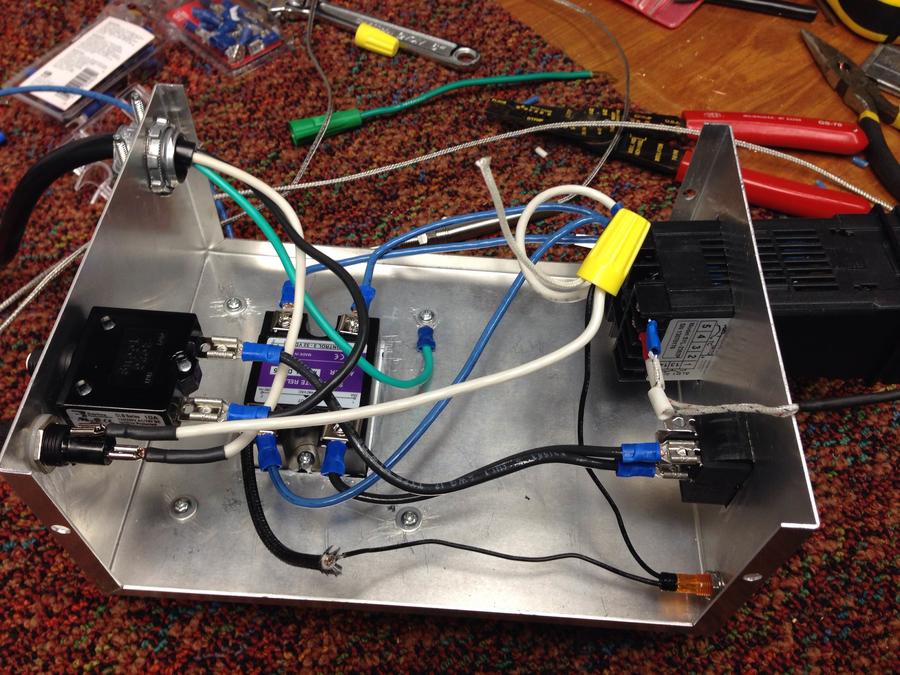

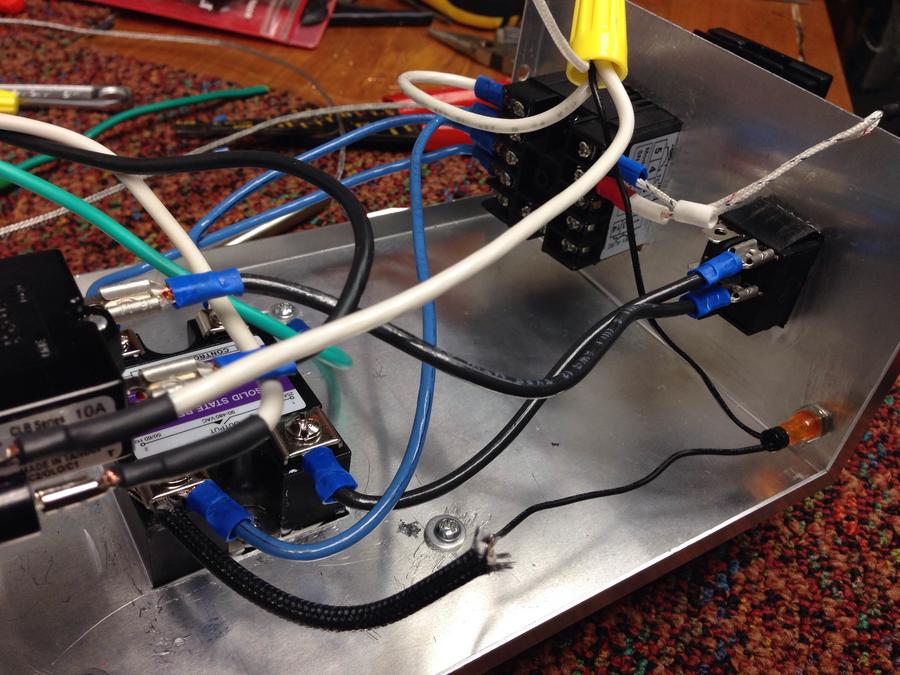

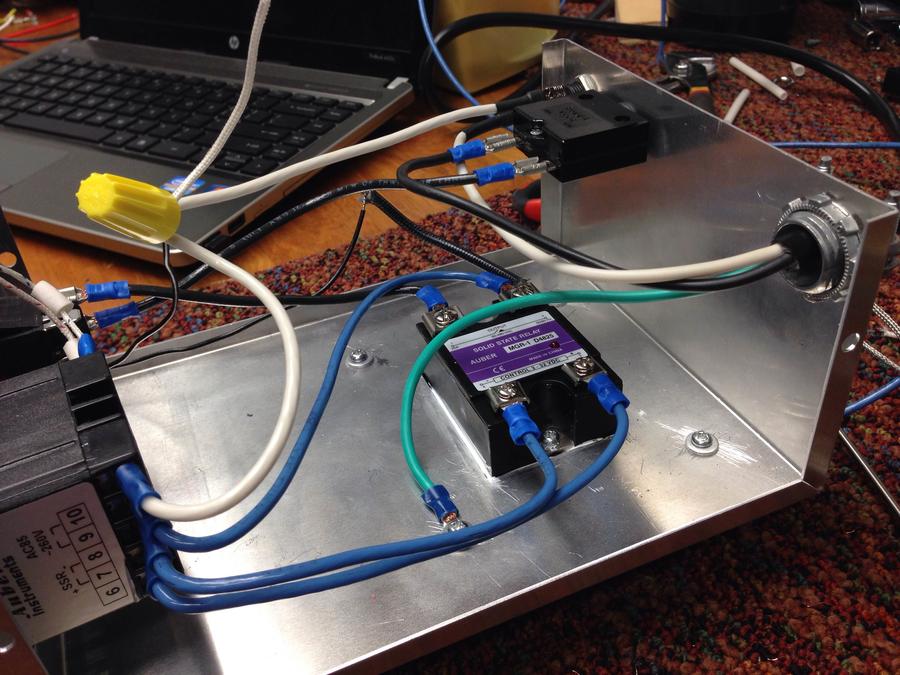

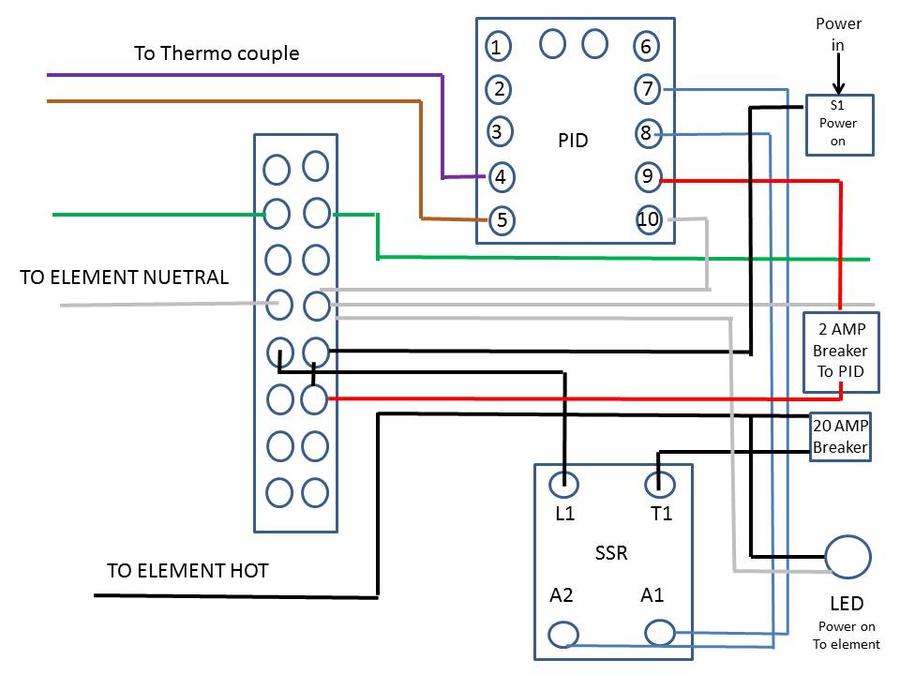

Okay, I have looked at no less than 10 different wiring diagrams/schematics. My eyeballs are burning after reading so many posts....and Im still not sure this is hooked up correctly. Is there anyone out there who can shed a little light on how to hook this thing up?

The white and black high-temp wires are where I would hook in the 1000w burner. The LED should be "on" when the burner is "on"

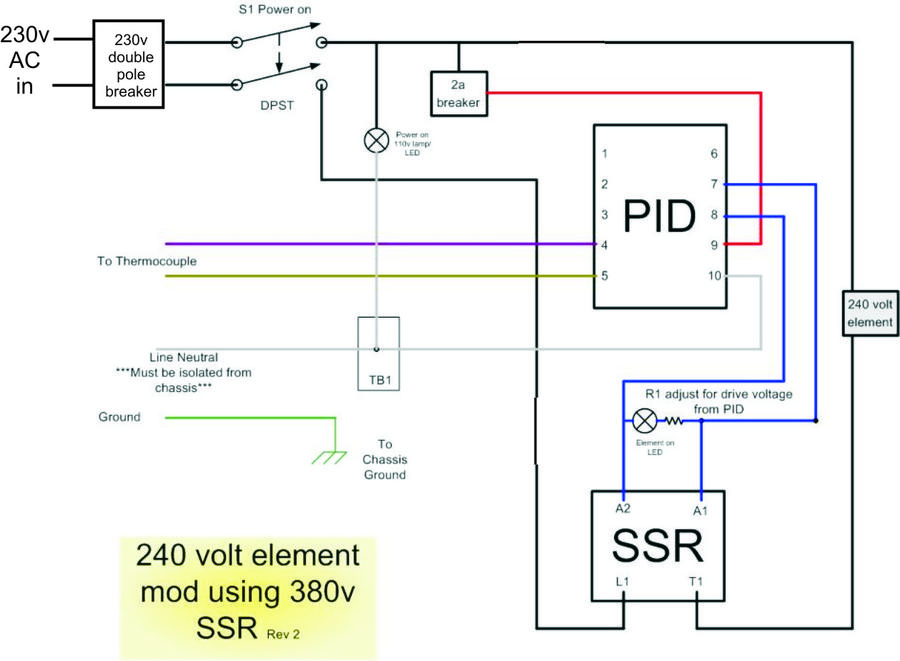

I want the whole setup switched. The burner should be protected with the 10A breaker and the PID should be protected by the 2a fuse.

So is this hooked up right or am I way off?

I am going crazy!!!

The white and black high-temp wires are where I would hook in the 1000w burner. The LED should be "on" when the burner is "on"

I want the whole setup switched. The burner should be protected with the 10A breaker and the PID should be protected by the 2a fuse.

So is this hooked up right or am I way off?

I am going crazy!!!

Last edited: