- Oct 7, 2014

- 19

- 10

Hi im from england and had not heard of smokers untill recently never seen one dont know anyone who has. I work as a welder and was making a barrel bbq out off stainless 16" pipe until I came across bbq smokers online. Now I really want one lol.

Iv done a bit or research which is how I came across this gold mine of a forum and think I want to make an offset reverse flow smoker.

Do I need a heat deflector

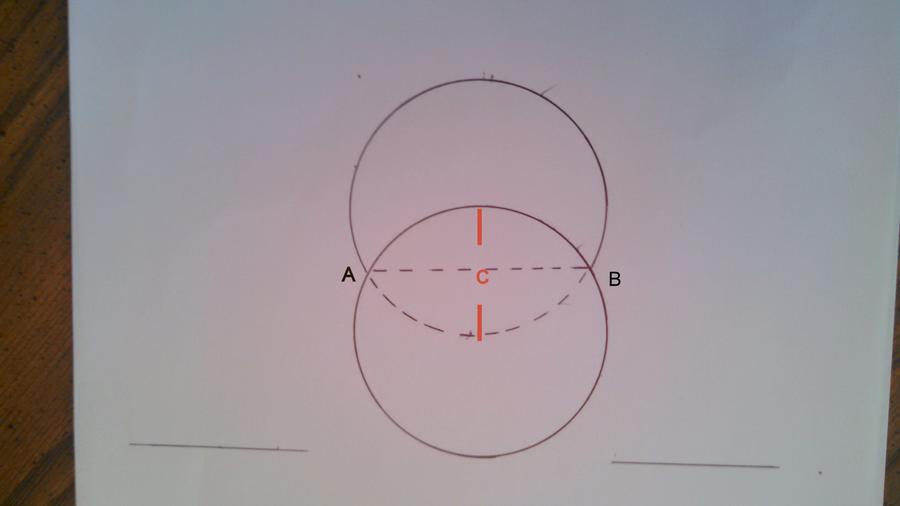

im unsure how to fo about a baffle plate. Do I need to put holes in it that start off small firebox side then get bigger as I get to the opposite side?

Should I cut a drainhole under the baffel plate to remove fat or make a drip tray above baffle leading to a hole in the side of the cooking chamber with an outlet valve.

as I was making a barrel style bbq iv cut the pipe im using in half. Will weld it back together but thought it would be easier to fit baffel etc first.

Sorry this is a bit longwinded but iv got so many questions and no one to ask.

heres some pics off the scrap material im hope to use. Its all stainless hope not to have to buy anything apart from temp gauges

Iv done a bit or research which is how I came across this gold mine of a forum and think I want to make an offset reverse flow smoker.

Do I need a heat deflector

im unsure how to fo about a baffle plate. Do I need to put holes in it that start off small firebox side then get bigger as I get to the opposite side?

Should I cut a drainhole under the baffel plate to remove fat or make a drip tray above baffle leading to a hole in the side of the cooking chamber with an outlet valve.

as I was making a barrel style bbq iv cut the pipe im using in half. Will weld it back together but thought it would be easier to fit baffel etc first.

Sorry this is a bit longwinded but iv got so many questions and no one to ask.

heres some pics off the scrap material im hope to use. Its all stainless hope not to have to buy anything apart from temp gauges