- Jun 9, 2014

- 8

- 10

Hi!

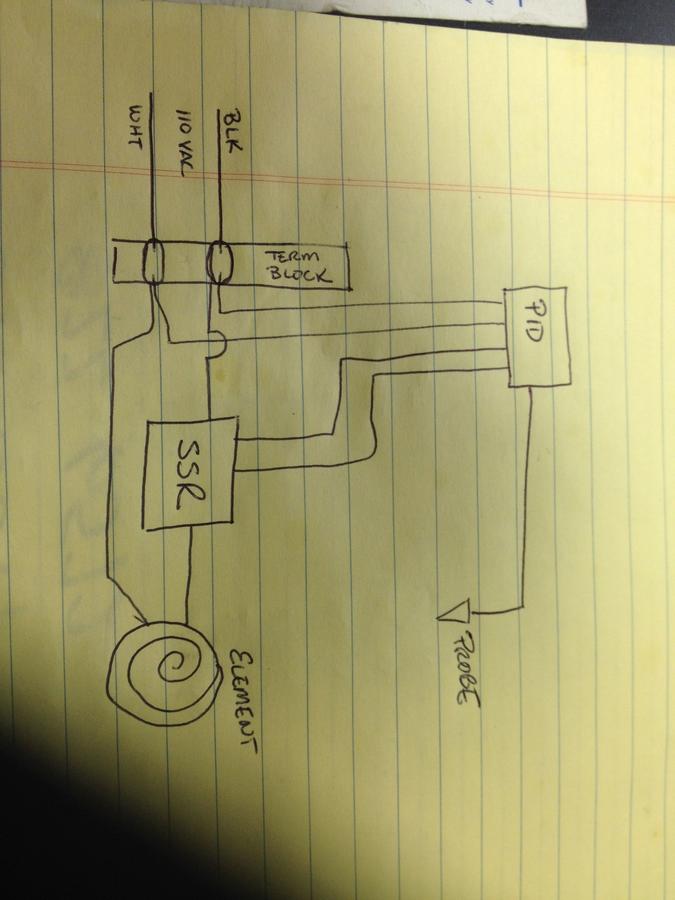

I am using a Mypin PID, and have hooked it up:

110v coming into terminals 1 & 2

Terminals 3 & 4 going to the SSR

Termianls 7 & 8 attached to the thermocouple.

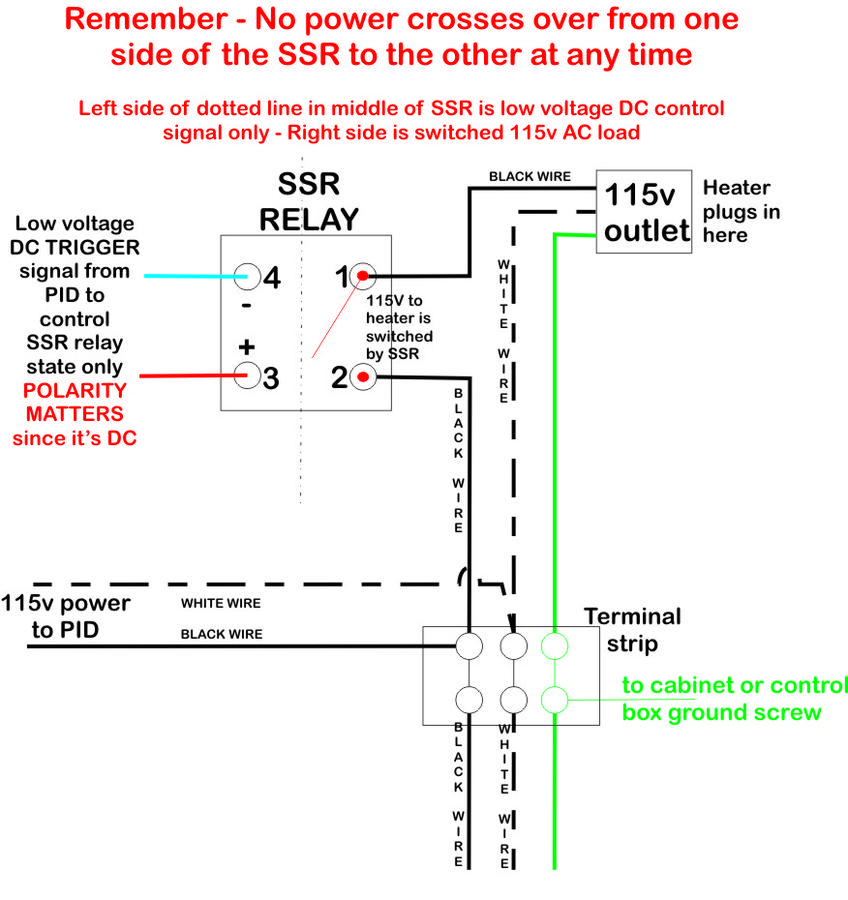

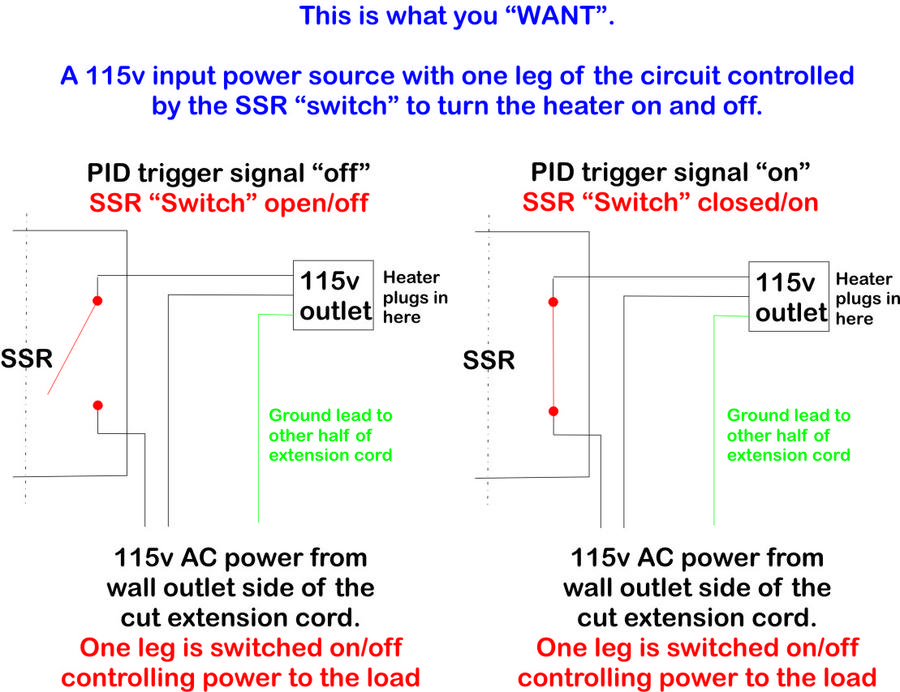

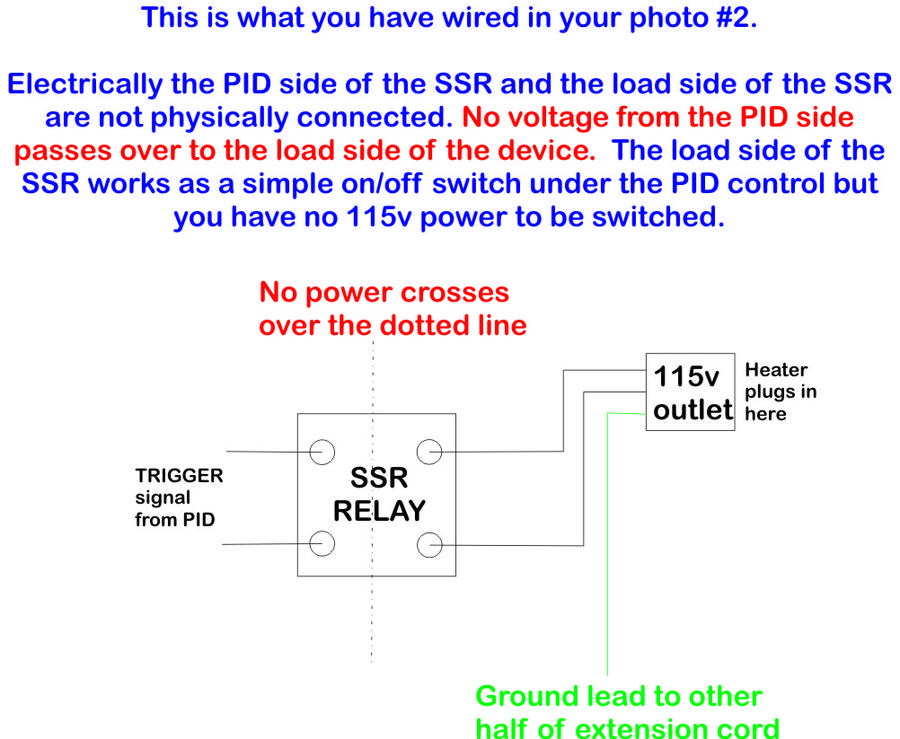

I think that the problem is that my SSR needs 110v to switch on, it is a heavy duty one 240v output for my oven. I am thinking that the signal from the PID is too weak to switch the SSR. Can anyone help me configure my PID so that the switch signal is 110v?

Thanks!

I am using a Mypin PID, and have hooked it up:

110v coming into terminals 1 & 2

Terminals 3 & 4 going to the SSR

Termianls 7 & 8 attached to the thermocouple.

I think that the problem is that my SSR needs 110v to switch on, it is a heavy duty one 240v output for my oven. I am thinking that the signal from the PID is too weak to switch the SSR. Can anyone help me configure my PID so that the switch signal is 110v?

Thanks!