Got the grease drain and clean-out drain installed.

Started by opening up a section of pipe and welding on a pipe nipple for each drain.

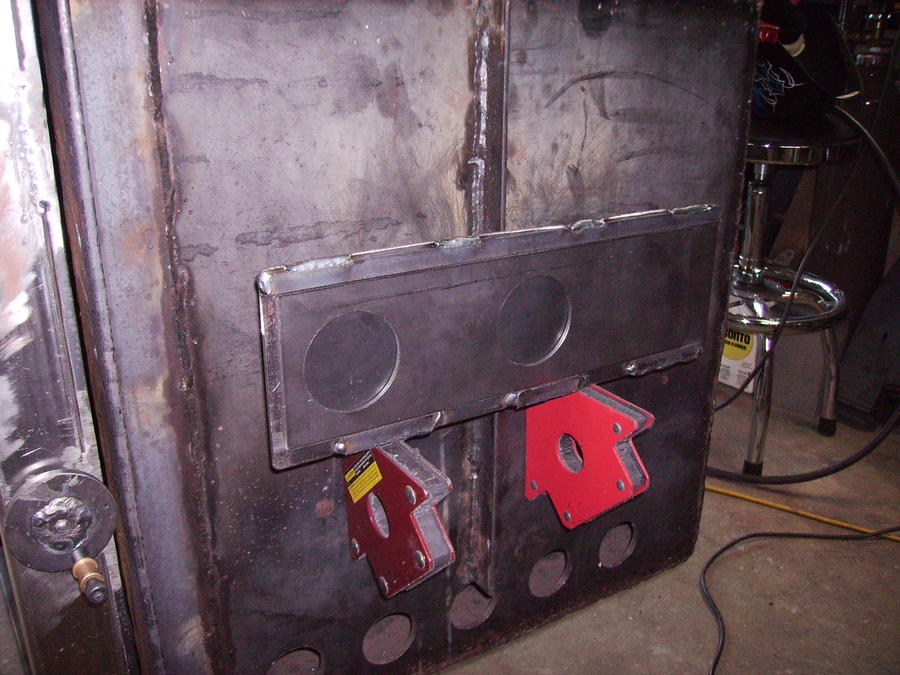

Welded onto side of cook chamber.

Put in the anti-tip tabs for the cooking grates.

That is all the progress for this weekend.

Tomorrow gonna go jump out of a perfectly good airplane, so the CC door will have to wait until next weekend.

Started by opening up a section of pipe and welding on a pipe nipple for each drain.

Welded onto side of cook chamber.

Put in the anti-tip tabs for the cooking grates.

That is all the progress for this weekend.

Tomorrow gonna go jump out of a perfectly good airplane, so the CC door will have to wait until next weekend.