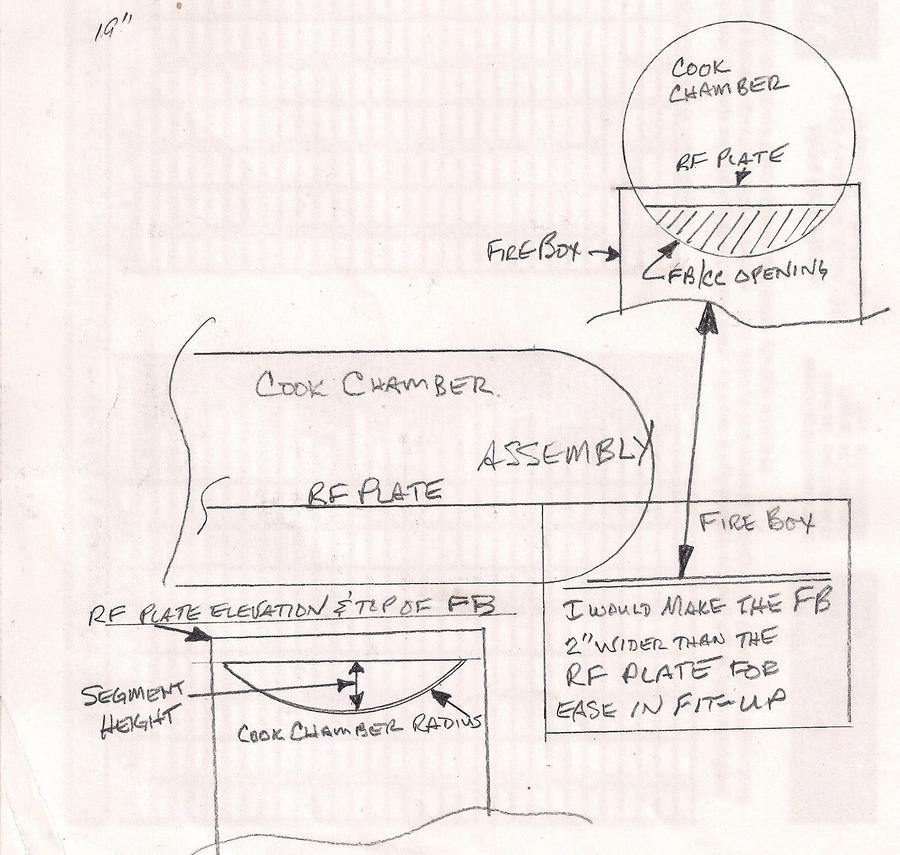

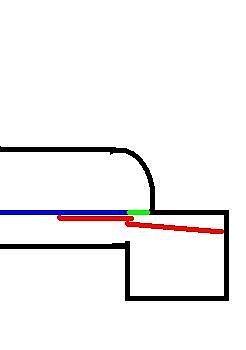

I'm new to this site, joined today hoping to get some help and feedback on my first RF smoker build. I have been using a 55 gallon drum smoker for a couple of years while looking for an old propane tank for just as long. Last week I had a friend give me a 132 gallon tank from his cabin in the mountains that needed to be replaced. So here we go, I read up on cutting a tank open and after many sleepless nights and internet research I cut it open the other day. I'm glad to say no big explosions, it only took me about 2-3 hours of standing there looking at it to get up enough nerve to climb on and cut away. I should say we filled it up with water and emptied it, then let it sit for a bit before doing so. The other guy in the photos is my good friend who just happens to be an iron worker so the welding part is covered. any input or suggestions would be most appreciated as I don't want to mess this up and hopefully end up with a long lasting great cooking smoker !

Here is a few first day photos

Here is a few first day photos