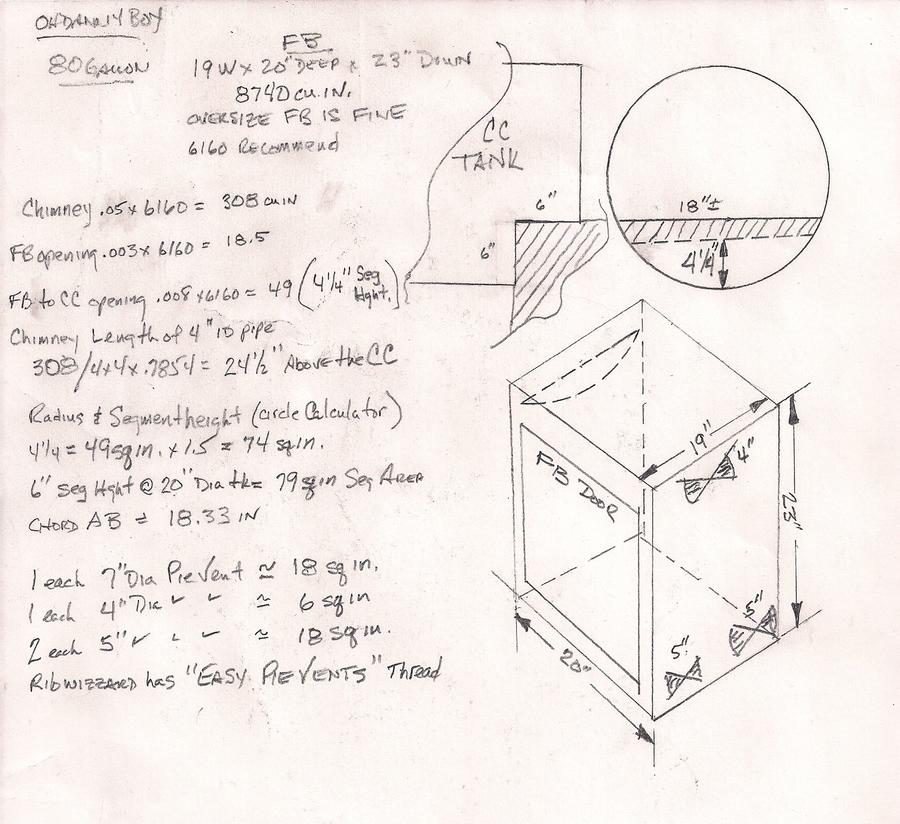

Hello. This is my first build. i plan on making a reverse flow smoker. I used the feldon calculator to get the size of the firebox size correct. What I have is a 80 gallon tank. It measures 20" ID and around 65" long. 5/16" thick Tank. The FB is 1/4" thick, 20" deep 19" wide and 23" down but the bottom 5 inches are going to be used as the opening if the air vents and also a ash pan. I'm assuming the internal firebox height would be 18" then. The calculator says:

FB specified 6840

FB recommended 6160

4" pipe @27.23" long

Half moon opening 11.80"

FB to CC 54.72 square

I already cut the opening on the tank and should have waited. Here's where I doubt myself. I cut the opening 6" deep and 6"height for the firebox to sit in the CC. Did I take too much off?

![GALLERY]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

FB specified 6840

FB recommended 6160

4" pipe @27.23" long

Half moon opening 11.80"

FB to CC 54.72 square

I already cut the opening on the tank and should have waited. Here's where I doubt myself. I cut the opening 6" deep and 6"height for the firebox to sit in the CC. Did I take too much off?