-Kurt@Sigmo does the fan controller have a three prong plug so it's grounded? I couldn't tell. If it does I guess it would run mes heating elements being 120v 15A = 1,800W. Just wondering if it would work. If it would then you could turn it on full to preheat and switch to variable without adjusting the dial. As well as bumping the heat up on full for a minute then switching back to variable during a smoke without touching the dial. Keeping my eyes open for when my electronics fail. I may try a rheostat before a PID. I like that switch.

-Kurt

Has Anyone Fooled the MES Temp Sensor Before?

- Thread starter tallbm

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Kurt, I believe it does have the 3 prong plug (99% sure). I looked at it this weekend when it came in the mail but I won't be able to confirm 100% until I get back to it this weekend.

-Kurt

I believe you could do what you desire with this controller to make your smoker into an analogue style one. I thought I read about someone doing that here with their MES while still using the stock MES electronics for the temp sensing and such. They just simply rewired so the controller was no longer connected to the heating element and used the dial to control power to the heating element. They used the onboard MES electronics and thermometer to read temp and then they would manually adjust the power to the element with the dial.

I'm pretty sure it is a 3 prong all the way through because I have it on my todo list to figure out how I'm going to ground fan motor when I build a chord for it. My guess is I could simply just run the ground through the MES backing down to the same location the MES using for a ground. I have a strong feeling I will put the fan in the back of the MES to stir the air inside. I'm going for a keep it simple keep it stupid approach for the fan portion of the modification. Putting it in the back and piggybacking off any existing wiring strategy, etc. is a simple way to go and I think any stirring will be a noticeable improvement even if it is not the most ideal stirring setup.

I also need to figure out how I'm going to drill the hole and insert the fan shaft through the body of the MES. I want to keep smoker/air from going into the body and insulation of the smoker.

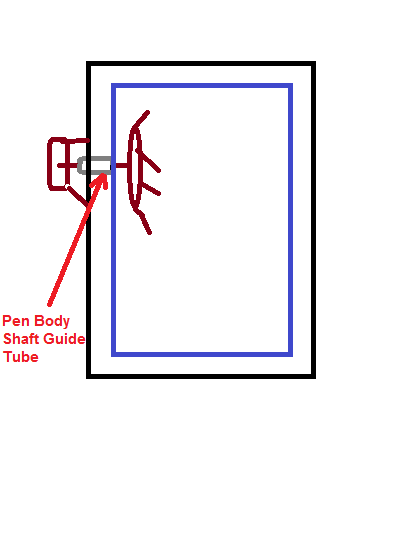

I think I am going to buy a stainless steel pen, remove the guts, then cut it to the proper length to use it as as fan shaft guide tube. I would then drill holes to accommodate the pen body shaft guide tube and"fasten" it to the back of the inside of the MES inner chamber while having it stick just outside the back of the MES so I can pull the back off at will with no issue from this tube. See my ugly attempt at what this would look like below lol

Cheap stainless steel pen like this or something similar.

My ugly sketch as an idea not as an exact schematic, I don't know where actual fan placement will be yet:

@TallBM

Thanks for the controller input. Like I said I like the switch from full to variable. This is for down the road when contrllers fail. I though about a fan like you and Sigmo are doing to mix air evenly in the smoker awhile back but it was just a thought. I thought about putting the fan in the bottom corner at the door on the hinge side of the gen 1facing the latch side so a current would start out going across the bottom face of the door, and rise with the air coming in from the mailbox mod, going the same direction.

The pen grommet sounds like a good idea to keep insulation where it's supposed to be. And the pen tapers so that maybe good to use if possible. I don't know.

-Kurt

Thanks for the controller input. Like I said I like the switch from full to variable. This is for down the road when contrllers fail. I though about a fan like you and Sigmo are doing to mix air evenly in the smoker awhile back but it was just a thought. I thought about putting the fan in the bottom corner at the door on the hinge side of the gen 1facing the latch side so a current would start out going across the bottom face of the door, and rise with the air coming in from the mailbox mod, going the same direction.

The pen grommet sounds like a good idea to keep insulation where it's supposed to be. And the pen tapers so that maybe good to use if possible. I don't know.

-Kurt

Hi, Guys!

I think the controller you're looking at, Dr K, will work as TallBM described.

The only real drawback I see with it is that you will no longer have a thermostat. Instead, you'll just be adjusting the power to the heating element directly yourself with the knob. So you'll have to constantly monitor the temperature in the smoker and adjust the power to the heating element yourself.

I've gotten spoiled by the MES, and I like to be able to set the temperature of the smoker, then walk away from it and have a thermostat maintain the temperature I've set. So that's one of the main things I really like about these electric smokers versus (in my case) the charcoal unit I have. However, if you'll be tending the smoker during the run anyhow, then the control you'll looking at would likely work just fine. It won't be any different than running a charcoal or gas smoker in that regard, and really, the charcoal unit of mine has worked just fine.

You'll probably get a good feel for what settings of the knob work the best for different meats and weather conditions just like we do when running a charcoal unit. But it will be a lot easier for you to adjust the power than it is with a charcoal smoker.

I'd do like TallBM suggested and use a three-wire power cord. Use the hot and neutral to power the heating element, but wire it so that the snap-disk thermal cut-off device is still in that circuit. Then connect a good ground from the chassis of the smoker to the grounding wire of that three wire cord. Then the ground pin of the controller will carry that ground through to the ground of the receptacle into which the controller is plugged. That way, the controller and the smoker will both be grounded.

TallBM:

I like the idea of a sleeve between the inside of the smoker and the outer wall to seal things off from the insulation space. It would be good to keep moisture and smoke out of that space, I think!

Maybe a guy could use some high temperature RTV to seal both sides (or at least the inside end) of the sleeve tube. But the tapered pen casing might work great just by itself because you could push it into the hole from the inside until it jams in place and makes a seal to the inside wall of the smoker. I'm going to want to do the same thing for mine. I don't like the idea of condensation forming in the insulation space. I want a "vapor barrier" like you'd install in the walls of a house or building, I guess! :)

I found out Opto 22 has an app for Android or IOS devices to let you access various things over a WiFi network to which the controllers and I/O are connected. I just played with it, and it works great, but I'll have to use one of their newer Snap PAC controllers to have access to the "Strategy Tags". The older model controller I tried this with lets me look at I/O, and control it as well, but it would be more convenient to be able to adjust variables, tables, etc., in the running strategy, and the older controllers don't know how to do that. I've got newer controllers laying around, so I'll use one of those and try that out when I get the chance.

I was thinking I'd need to use a laptop or other PC connected to the network to adjust and monitor things, but this little app, running on a tablet or phone will do everything I'd really need, too, so that'll be cool.

They've got a full-blown system for remote access to their systems that lets you create very user-friendly Man Machine Interfaces to run on phones or tablets, and connect from anywhere that you have internet access, but they actually want real money for that setup!

Being a cheapskate, I want to do this all with bits and pieces I already have laying around and with their free software. This app was just $5, so that's acceptable, I guess.

Woo Hoo! I can see the temperature in my office now from anywhere my WiFi reaches, and I can turn a light on and off as well as adjust the duty cycles of some Time Period Outputs. Yee Haw! (It doesn't take much to amuse a nerd, I guess) ;)

When I get the new style controller set up and configured, I will be able to adjust variables within a running strategy from my phone or tablet, which will let me adjust setpoints and such. There are ways to let this work over the internet, too, but I'm not sure that's really necessary since I'd at least be somewhere around the house while smoking stuff. Just being able to monitor and control things from an easy chair or the like without needing to go out in the cold is nice. That's one of the features I've always liked about the MES (and similar smokers). So it will be nice not to lose that feature.

And that looks like one of the nice features of the system you're using, too. Remote control and monitoring is nice. I'm thoroughly spoiled.

I think the controller you're looking at, Dr K, will work as TallBM described.

The only real drawback I see with it is that you will no longer have a thermostat. Instead, you'll just be adjusting the power to the heating element directly yourself with the knob. So you'll have to constantly monitor the temperature in the smoker and adjust the power to the heating element yourself.

I've gotten spoiled by the MES, and I like to be able to set the temperature of the smoker, then walk away from it and have a thermostat maintain the temperature I've set. So that's one of the main things I really like about these electric smokers versus (in my case) the charcoal unit I have. However, if you'll be tending the smoker during the run anyhow, then the control you'll looking at would likely work just fine. It won't be any different than running a charcoal or gas smoker in that regard, and really, the charcoal unit of mine has worked just fine.

You'll probably get a good feel for what settings of the knob work the best for different meats and weather conditions just like we do when running a charcoal unit. But it will be a lot easier for you to adjust the power than it is with a charcoal smoker.

I'd do like TallBM suggested and use a three-wire power cord. Use the hot and neutral to power the heating element, but wire it so that the snap-disk thermal cut-off device is still in that circuit. Then connect a good ground from the chassis of the smoker to the grounding wire of that three wire cord. Then the ground pin of the controller will carry that ground through to the ground of the receptacle into which the controller is plugged. That way, the controller and the smoker will both be grounded.

TallBM:

I like the idea of a sleeve between the inside of the smoker and the outer wall to seal things off from the insulation space. It would be good to keep moisture and smoke out of that space, I think!

Maybe a guy could use some high temperature RTV to seal both sides (or at least the inside end) of the sleeve tube. But the tapered pen casing might work great just by itself because you could push it into the hole from the inside until it jams in place and makes a seal to the inside wall of the smoker. I'm going to want to do the same thing for mine. I don't like the idea of condensation forming in the insulation space. I want a "vapor barrier" like you'd install in the walls of a house or building, I guess! :)

I found out Opto 22 has an app for Android or IOS devices to let you access various things over a WiFi network to which the controllers and I/O are connected. I just played with it, and it works great, but I'll have to use one of their newer Snap PAC controllers to have access to the "Strategy Tags". The older model controller I tried this with lets me look at I/O, and control it as well, but it would be more convenient to be able to adjust variables, tables, etc., in the running strategy, and the older controllers don't know how to do that. I've got newer controllers laying around, so I'll use one of those and try that out when I get the chance.

I was thinking I'd need to use a laptop or other PC connected to the network to adjust and monitor things, but this little app, running on a tablet or phone will do everything I'd really need, too, so that'll be cool.

They've got a full-blown system for remote access to their systems that lets you create very user-friendly Man Machine Interfaces to run on phones or tablets, and connect from anywhere that you have internet access, but they actually want real money for that setup!

Being a cheapskate, I want to do this all with bits and pieces I already have laying around and with their free software. This app was just $5, so that's acceptable, I guess.

Woo Hoo! I can see the temperature in my office now from anywhere my WiFi reaches, and I can turn a light on and off as well as adjust the duty cycles of some Time Period Outputs. Yee Haw! (It doesn't take much to amuse a nerd, I guess) ;)

When I get the new style controller set up and configured, I will be able to adjust variables within a running strategy from my phone or tablet, which will let me adjust setpoints and such. There are ways to let this work over the internet, too, but I'm not sure that's really necessary since I'd at least be somewhere around the house while smoking stuff. Just being able to monitor and control things from an easy chair or the like without needing to go out in the cold is nice. That's one of the features I've always liked about the MES (and similar smokers). So it will be nice not to lose that feature.

And that looks like one of the nice features of the system you're using, too. Remote control and monitoring is nice. I'm thoroughly spoiled.

Wow Sigmo, it looks like you are well on your way to an awesome controller setup with the apps and all.

You might want to check and see if you can still connect with your app when you are out of your personal wifi network range.

I know network enabled security cameras do this with their apps so you can view live feeds, few recorded pics and videos, turn on/of alerts, etc. I don't see why your app would not work the same way once setup, but I guess this is something you will want to confirm while at work or at the grocery store some day.

I think I have all of my pieces in. For the sleeve I was thinking I would high temp silicone it to the the inner chamber and use some 600F flue tape to assist and then let the tapered end sit outside the back end and allow the taper to provide a metal to metal "seal" that I would then reinforce with the 600F flue tape. Or vise-versa...something along those lines. I'll know more when I get down and dirty with the parts and the MES.

The Heater Meter already comes with an app (free I believe) and I believe I can access the controller from my phone as long as it is on and connected to my wifi network. So I can kick the smoker on from the grocery store to start warming up when I find a nice piece of marked down meat :D

Also I have wired in a 350F manual reset into my Gen 2 guinea pig MES I have setup for my mother. This way a 325F temp can be set ONLY for chicken/turkey with skin. All other smokes will be no higher than 275F. I will get acceptable chicken skin form an MES dammit!!! :)

I'm about to play with all of my HeaterMeter/LinkMeter parts this evening so I can figure out the final piece I am waiting to buy. The final piece is the project box/enclosure once I know how much room things will take up.

I'm like you, very excited and happy to see things coming together!

You might want to check and see if you can still connect with your app when you are out of your personal wifi network range.

I know network enabled security cameras do this with their apps so you can view live feeds, few recorded pics and videos, turn on/of alerts, etc. I don't see why your app would not work the same way once setup, but I guess this is something you will want to confirm while at work or at the grocery store some day.

I think I have all of my pieces in. For the sleeve I was thinking I would high temp silicone it to the the inner chamber and use some 600F flue tape to assist and then let the tapered end sit outside the back end and allow the taper to provide a metal to metal "seal" that I would then reinforce with the 600F flue tape. Or vise-versa...something along those lines. I'll know more when I get down and dirty with the parts and the MES.

The Heater Meter already comes with an app (free I believe) and I believe I can access the controller from my phone as long as it is on and connected to my wifi network. So I can kick the smoker on from the grocery store to start warming up when I find a nice piece of marked down meat :D

Also I have wired in a 350F manual reset into my Gen 2 guinea pig MES I have setup for my mother. This way a 325F temp can be set ONLY for chicken/turkey with skin. All other smokes will be no higher than 275F. I will get acceptable chicken skin form an MES dammit!!! :)

I'm about to play with all of my HeaterMeter/LinkMeter parts this evening so I can figure out the final piece I am waiting to buy. The final piece is the project box/enclosure once I know how much room things will take up.

I'm like you, very excited and happy to see things coming together!

Well I figured I would kind of put the concluding post on this thread.

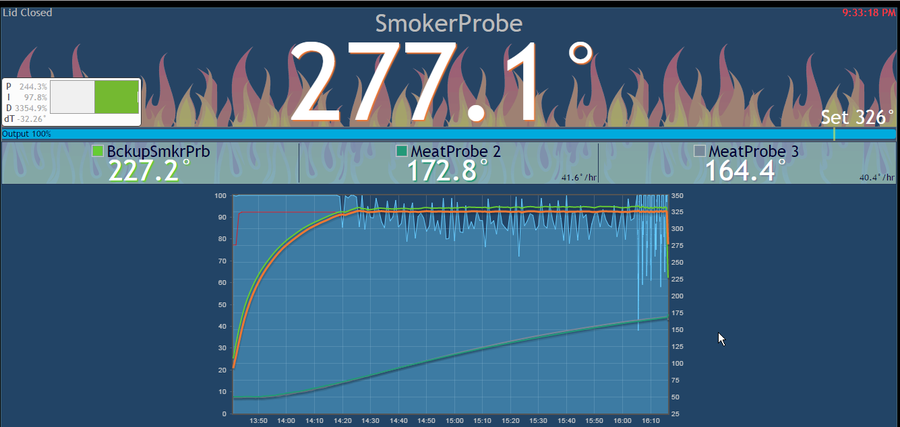

I decided to rewire the MES and go with a PID controller for it. I went unconventional and used the HeaterMeter controller and I feel I have completely eliminated the Temp Swings!

I also installed a convection fan to try and even out the temps throughout the smoker. The fan has improved things quite a bit BUT it seems that there is just NO way to get the entire smoker to be consistently even. Between racks there will be differences in temp and even along a rack there will be differences. The fan has at least helped the differences become much more consistent. For example if the bottom rack is right on then the top rack may be off by 25 degrees but across the rack it is close to a 25 degree difference and seems to hold true to that difference. I was not able to make the top and bottom racks the same but I think this is about the best that can be done with the device. It is a smoker not a convection oven and vents smoke plus air right out of the top so it is more difficult to retain temp at the top most racks that would be the same as the temp at the bottom most racks.

In any case I bypassed the stock MES controller and probes and I have improved upon my smokers biggest issues. Soon I hope to post about all of my mods but as for now here is the thread with my mods being discussed as I was working through them.

I wish everyone the best with their MES temp issues and I hope you enjoy my little journey and the info I've shared. Thanks! :)

http://www.smokingmeatforums.com/t/261790/mes-mod-madness-teaser-pics

Pic of steady temps using my HeaterMeater PID controller, look at the orange and light green line at the top of the pic holding steady :)

I decided to rewire the MES and go with a PID controller for it. I went unconventional and used the HeaterMeter controller and I feel I have completely eliminated the Temp Swings!

I also installed a convection fan to try and even out the temps throughout the smoker. The fan has improved things quite a bit BUT it seems that there is just NO way to get the entire smoker to be consistently even. Between racks there will be differences in temp and even along a rack there will be differences. The fan has at least helped the differences become much more consistent. For example if the bottom rack is right on then the top rack may be off by 25 degrees but across the rack it is close to a 25 degree difference and seems to hold true to that difference. I was not able to make the top and bottom racks the same but I think this is about the best that can be done with the device. It is a smoker not a convection oven and vents smoke plus air right out of the top so it is more difficult to retain temp at the top most racks that would be the same as the temp at the bottom most racks.

In any case I bypassed the stock MES controller and probes and I have improved upon my smokers biggest issues. Soon I hope to post about all of my mods but as for now here is the thread with my mods being discussed as I was working through them.

I wish everyone the best with their MES temp issues and I hope you enjoy my little journey and the info I've shared. Thanks! :)

http://www.smokingmeatforums.com/t/261790/mes-mod-madness-teaser-pics

Pic of steady temps using my HeaterMeater PID controller, look at the orange and light green line at the top of the pic holding steady :)

Last edited:

downeast smoker

Newbie

Bear, I am doing my second smoke with my MES30 (brisket this time) and now that I have a good digital thermometer (ThermPro TP-20) I see that when my MES temp guage says 240, the actual temp (with probe hanging just above the meat) is only about 220. So I am doing what you suggested here and raising the setting on the MES to get the desired temp based on what my ThermPro is telling me. I will be contacting Masterbilt about this and see what they say or will do about it. I will do the boil test which I just read about later, but when I took the ThermPro out of the box, installed the batteries and turned it on, the temp reading was 73 degrees, which was exactly the anbient temp in the room I was in, so I am quite sure the ThermPro is accurate. I think the fact that I was cooking the Boston Butt at a temp 20 or 25 degrees lower than I thought it was at is a reason I was having a problem getting smoke.

Sounds better than before.

Bear, I am doing my second smoke with my MES30 (brisket this time) and now that I have a good digital thermometer (ThermPro TP-20) I see that when my MES temp guage says 240, the actual temp (with probe hanging just above the meat) is only about 220. So I am doing what you suggested here and raising the setting on the MES to get the desired temp based on what my ThermPro is telling me. I will be contacting Masterbilt about this and see what they say or will do about it. I will do the boil test which I just read about later, but when I took the ThermPro out of the box, installed the batteries and turned it on, the temp reading was 73 degrees, which was exactly the anbient temp in the room I was in, so I am quite sure the ThermPro is accurate. I think the fact that I was cooking the Boston Butt at a temp 20 or 25 degrees lower than I thought it was at is a reason I was having a problem getting smoke.

However if it continues to be more than 15° lower (actual temp) than the MES says, I would contact them too, because if you have to set your MES to 240° to get 220°, or set 260° to get 240°, that means if you set it to the MAX--275° the highest you can get is 255° at best.

You paid for a Smoker that could get to 275° and stay there as long as you want it to.

I think their guarantee is +/- 15°.

Note: Being 20 or 25 degrees lower than you thought shouldn't affect the smoke. If there are no other problems you should get the same smoke at 220° as you get at 260°.

Bear

PaddlepopLion307

Newbie

- Jan 11, 2019

- 2

- 0

This thread was incredibly helpful and I have now fooled the sensor.

I folded a few layers of foil and folded a flap 2" from the end. I put a rack on the bottom rail just above the factory water tray and put the foil on top of the rack with the flap pressed against the wall under the rack.

This formed a sort of scoop which directs hot air away from the back wall where the sensor is and towards the door.

Ontop of this I put my water tray further sheilds the sensor and now im able to get the general unit temperature up past the maximum of 275. I have reached up to over 300 so now i can cook my briskets in less than 8 hours!

I might make up a custom rack to snuggly fit the shape of the wall. Will post pics when I do. I have an idea for air circulation without installing an active fan by using the custom rack to evenly distribute the air flow.

I folded a few layers of foil and folded a flap 2" from the end. I put a rack on the bottom rail just above the factory water tray and put the foil on top of the rack with the flap pressed against the wall under the rack.

This formed a sort of scoop which directs hot air away from the back wall where the sensor is and towards the door.

Ontop of this I put my water tray further sheilds the sensor and now im able to get the general unit temperature up past the maximum of 275. I have reached up to over 300 so now i can cook my briskets in less than 8 hours!

I might make up a custom rack to snuggly fit the shape of the wall. Will post pics when I do. I have an idea for air circulation without installing an active fan by using the custom rack to evenly distribute the air flow.

This thread was incredibly helpful and I have now fooled the sensor.

I folded a few layers of foil and folded a flap 2" from the end. I put a rack on the bottom rail just above the factory water tray and put the foil on top of the rack with the flap pressed against the wall under the rack.

This formed a sort of scoop which directs hot air away from the back wall where the sensor is and towards the door.

Ontop of this I put my water tray further sheilds the sensor and now im able to get the general unit temperature up past the maximum of 275. I have reached up to over 300 so now i can cook my briskets in less than 8 hours!

I might make up a custom rack to snuggly fit the shape of the wall. Will post pics when I do. I have an idea for air circulation without installing an active fan by using the custom rack to evenly distribute the air flow.

Hi there and welcome!

That is some cool info to know.

Just a word of caution though. The MES has foam insulation that will have a certain max operating temperature limit. No one I know of seems to know what that limit is and if I remember correctly, every can of foam insulation I googled in the past didnt have a listed limit or one over 300F. The industrial stuff can go higher but that isn't something the average Joe would be handling. My GUESS is that the existing MES foam insulation probably has a continuous temp rating in the 330-350F range.

If you push your smoker too hot for too long your insulation may burn up, gas out, and or catch fire.

I can make my smoker go to 325F but I only do it for my fast poultry smokes to get edible skin rather than leathery skin. Other than that I don't go over 275F since that was the top temp the MES was "supposed" to hit. Be cautions of 4+ hour smokes and getting too hot.

I hope this info helps and best of luck with the smoking and temp control on the MES. We all fight that battle to some extent with the MES :)

PaddlepopLion307

Newbie

- Jan 11, 2019

- 2

- 0

Hi there and welcome!

That is some cool info to know.

Just a word of caution though. The MES has foam insulation that will have a certain max operating temperature limit. No one I know of seems to know what that limit is and if I remember correctly, every can of foam insulation I googled in the past didnt have a listed limit or one over 300F. The industrial stuff can go higher but that isn't something the average Joe would be handling. My GUESS is that the existing MES foam insulation probably has a continuous temp rating in the 330-350F range.

If you push your smoker too hot for too long your insulation may burn up, gas out, and or catch fire.

I can make my smoker go to 325F but I only do it for my fast poultry smokes to get edible skin rather than leathery skin. Other than that I don't go over 275F since that was the top temp the MES was "supposed" to hit. Be cautions of 4+ hour smokes and getting too hot.

I hope this info helps and best of luck with the smoking and temp control on the MES. We all fight that battle to some extent with the MES :)

Yea thanks, I saw the post about the crackling noise someone noticed at 340f so its on my radar.

Ill report back if I run into any trouble!

A guy on FB drilled a hole just big enough in a cork to slide over the Mes sensor to get higher temps since his Mes maxed at 250 so now he gets 275 at second from top rack. I'm not sure if the cork has been cut to the length of the sensor, drilled all the way through and/or butts against the back wall. Enough heat from the back wall feeds the sensor. If I still used the Mes controller I'd give it a shot and run some tests since my Mes never got to 275.

Yea thanks, I saw the post about the crackling noise someone noticed at 340f so its on my radar.

Ill report back if I run into any trouble!

Yup---That was me with the "Crackling" insulation.

I would seriously avoid going over 330°, and wouldn't hold over 275° for any extended lengths of time.

Bear

This thread was incredibly helpful and I have now fooled the sensor.

I folded a few layers of foil and folded a flap 2" from the end. I put a rack on the bottom rail just above the factory water tray and put the foil on top of the rack with the flap pressed against the wall under the rack.

This formed a sort of scoop which directs hot air away from the back wall where the sensor is and towards the door.

Ontop of this I put my water tray further sheilds the sensor and now im able to get the general unit temperature up past the maximum of 275. I have reached up to over 300 so now i can cook my briskets in less than 8 hours!

I might make up a custom rack to snuggly fit the shape of the wall. Will post pics when I do. I have an idea for air circulation without installing an active fan by using the custom rack to evenly distribute the air flow.

Do you have a picture of this?

This thread was incredibly helpful and I have now fooled the sensor.

I folded a few layers of foil and folded a flap 2" from the end. I put a rack on the bottom rail just above the factory water tray and put the foil on top of the rack with the flap pressed against the wall under the rack.

This formed a sort of scoop which directs hot air away from the back wall where the sensor is and towards the door.

Ontop of this I put my water tray further sheilds the sensor and now im able to get the general unit temperature up past the maximum of 275. I have reached up to over 300 so now i can cook my briskets in less than 8 hours!

I might make up a custom rack to snuggly fit the shape of the wall. Will post pics when I do. I have an idea for air circulation without installing an active fan by using the custom rack to evenly distribute the air flow.

I giving this a shot. Does look like what you did? Water pan pretty close to probe.

Last edited:

I was able to get smoker to run 240 to 250 set at 275 configured like this which is where I want to be if it will stay like that.

Well I figured I would kind of put the concluding post on this thread.

I decided to rewire the MES and go with a PID controller for it. I went unconventional and used the HeaterMeter controller and I feel I have completely eliminated the Temp Swings!

I also installed a convection fan to try and even out the temps throughout the smoker. The fan has improved things quite a bit BUT it seems that there is just NO way to get the entire smoker to be consistently even. Between racks there will be differences in temp and even along a rack there will be differences. The fan has at least helped the differences become much more consistent. For example if the bottom rack is right on then the top rack may be off by 25 degrees but across the rack it is close to a 25 degree difference and seems to hold true to that difference. I was not able to make the top and bottom racks the same but I think this is about the best that can be done with the device. It is a smoker not a convection oven and vents smoke plus air right out of the top so it is more difficult to retain temp at the top most racks that would be the same as the temp at the bottom most racks.

In any case I bypassed the stock MES controller and probes and I have improved upon my smokers biggest issues. Soon I hope to post about all of my mods but as for now here is the thread with my mods being discussed as I was working through them.

I wish everyone the best with their MES temp issues and I hope you enjoy my little journey and the info I've shared. Thanks! :)

http://www.smokingmeatforums.com/t/261790/mes-mod-madness-teaser-pics

Pic of steady temps using my HeaterMeater PID controller, look at the orange and light green line at the top of the pic holding steady :)

Hey, it's only been a couple of years since I added anything to this thread! :)

I've been busy, and may still not get this all set up too soon, but:

Having set up a security camera system here, I've been through a lot of learning and work with that. And part of that lead me down the path of setting up my own VPN running on my router. The idea is to NEVER let any of these cheap security cameras communicate directly with the internet because most have back doors, and all of them are pretty easy to hack, so they're big targets for hackers. Once you give a camera access to your network, and also allow it to have access to the internet, you've set up a "man on the inside" that can spy on all of your network traffic and send whatever it wants to its masters (usually in China).

Anyhow, the upshot of having my own VPN running on my system is that my wife and I can open a secure tunnel to our home network from anywhere, and once that's "switched on", we can access our home network as if we were right there logged into that network. That opens up a lot of possibilities, and it also allows us to surf or shop online even if we're on a public network because all of our traffic is encrypted with 2048bit encryption both ways.

This is NOT the same as using a VPN service. It's our own VPN, running on our router. (There are other ways to do it, as well, but this was easy).

VPN services are also very handy, but for accessing gadgets on our home network remotely, having our own VPN is the way to achieve that goal securely, with no port forwarding, or other serious security issues.

I still need to modify the MES, but I'm also looking at getting a larger smoker as the starting point for these modifications. Someday I may actually get around to doing some of this! :)

Hey, it's only been a couple of years since I added anything to this thread! :)

I've been busy, and may still not get this all set up too soon, but:

Having set up a security camera system here, I've been through a lot of learning and work with that. And part of that lead me down the path of setting up my own VPN running on my router. The idea is to NEVER let any of these cheap security cameras communicate directly with the internet because most have back doors, and all of them are pretty easy to hack, so they're big targets for hackers. Once you give a camera access to your network, and also allow it to have access to the internet, you've set up a "man on the inside" that can spy on all of your network traffic and send whatever it wants to its masters (usually in China).

Anyhow, the upshot of having my own VPN running on my system is that my wife and I can open a secure tunnel to our home network from anywhere, and once that's "switched on", we can access our home network as if we were right there logged into that network. That opens up a lot of possibilities, and it also allows us to surf or shop online even if we're on a public network because all of our traffic is encrypted with 2048bit encryption both ways.

This is NOT the same as using a VPN service. It's our own VPN, running on our router. (There are other ways to do it, as well, but this was easy).

VPN services are also very handy, but for accessing gadgets on our home network remotely, having our own VPN is the way to achieve that goal securely, with no port forwarding, or other serious security issues.

I still need to modify the MES, but I'm also looking at getting a larger smoker as the starting point for these modifications. Someday I may actually get around to doing some of this! :)

I completely understand where you are going with it. I just chose to not open my HeaterMeter up to the internet hahaha. Also I got over the idea real quick that I would be away from my smoker or working it remotely while NOT at home. It is a very cool idea but not practical if you don't have someone within 10 seconds of the smoker should there be a flame up situation or anything else that could be dangerous or at least ruin the meat.

In any case a VPN is awesome to have regardless of using it to control and monitor a smoker :)

Yep. It's probably not a really good idea to leave this kind of thing unattended! I guess you could watch your porch going up in flames via the security cameras. At least for a while! ;)

I will say, though, that I frequently smoke pork butts overnight, and sleep while smoking. It's nice to be able to just roll over in bed and check things, but even that is potentially risky, for sure!

The security cam footage of a guy in pajamas desperately extinguishing what's left of his smoker would be pretty amusing on the evening news, though!

I will say, though, that I frequently smoke pork butts overnight, and sleep while smoking. It's nice to be able to just roll over in bed and check things, but even that is potentially risky, for sure!

The security cam footage of a guy in pajamas desperately extinguishing what's left of his smoker would be pretty amusing on the evening news, though!

Last edited:

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 18

- Views

- 3K

- Replies

- 8

- Views

- 461

- Replies

- 14

- Views

- 1K

- Replies

- 10

- Views

- 564

- Replies

- 11

- Views

- 1K

- Replies

- 6

- Views

- 743

- Replies

- 2

- Views

- 365

- Replies

- 0

- Views

- 327

Hot Threads

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 64

- Blowing Smoke Around the Smoker.

-

Questions for RecTeq owners

- Started by schlotz

- Replies: 61

- Blowing Smoke Around the Smoker.

-

Lost my dad yesterday

- Started by normanaj

- Replies: 35

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 33

- Sausage