First run on new reverse flow

- Thread starter hickorybutt

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

ribwizzard

Master of the Pit

Just kick you slippers off and rest those feet right on top of the firebox, as long as your beer don't freeze and it's still drinkable , you'll be alright.

I tried to smoke some ribs today. Wind gusts were 25-30mph. I never got up past 205*... I had to put the ribs in the oven.

I ran the smoker twice last weekend in normal weather conditions and it did fine. I held 300* just fine last week doing the same method. But this week the smoker never got hot. The wood just wouldn't catch. And I even started with a full chimney of lit coals. My dampers were wide open. I did have a camping chair turned over sitting in front of the damper to break the wind - would that restrict air flow and cause the fire to die out? It wasn't blocking the dampers, just sitting in front of them. If I didn't have the chair there, the wind would blow straight into the smoker. If I moved the chair and opened the SFB door, the wood would ignite and start burning. Then once I'd close the door hoping for it to start heating the smoker, it would smolder down and stop burning.

I'm getting really frustrated with inconsistent results. Thank God for an oven tonight. Otherwise I would have lost 4 racks of ribs and had to order pizza for our guests.

I ran the smoker twice last weekend in normal weather conditions and it did fine. I held 300* just fine last week doing the same method. But this week the smoker never got hot. The wood just wouldn't catch. And I even started with a full chimney of lit coals. My dampers were wide open. I did have a camping chair turned over sitting in front of the damper to break the wind - would that restrict air flow and cause the fire to die out? It wasn't blocking the dampers, just sitting in front of them. If I didn't have the chair there, the wind would blow straight into the smoker. If I moved the chair and opened the SFB door, the wood would ignite and start burning. Then once I'd close the door hoping for it to start heating the smoker, it would smolder down and stop burning.

I'm getting really frustrated with inconsistent results. Thank God for an oven tonight. Otherwise I would have lost 4 racks of ribs and had to order pizza for our guests.

lendecatural

Smoking Fanatic

I think you were just up against the cold, you were still cooking in single digits when considering the wind chill. The firebox, wood, and exhaust don't have enough thermal mass to overcome an effective 6 degree outside temperature....At least you got some smoke on them before you had to put them in the oven.

ribwizzard

Master of the Pit

I looked through this thread again to double check myself before writing my response.

First of all, it's a nice smoker, you did not go wrong for that price.

And what I'm thinking, from what you have logged so far on your results is that the exhaust is the root of your problem. Especially with that right angle turn in it. It's not letting the air flow freely enough to get a good draft.

With that size firebox, you should have been able to get that smoker up to a easy 350* , even in those temps. Your intake vent is huge, and if your running with the vents at 3/4 open to get to 300*, that's telling me that it's not letting the air out the other end. I'd like to see a good pic of the opening on the left side of the reverse flow plate, just to see how big that opening is, but I'm sure it's at least twice the size of the exhaust.

So why don't you talk to the builder, explain the problems you are having and tell him that you would like to pay him to redo the exhaust. With the right approach, might get him to do it free or next to nothing.

Once you get the exhaust squared away, the trick for cold weather cooking will be to get that baby up to 400* and get all that steel preheated good before bring the temp back down to where you want it. Then cook at a higher temp than you would on a warm day, say 325 or so,

First of all, it's a nice smoker, you did not go wrong for that price.

And what I'm thinking, from what you have logged so far on your results is that the exhaust is the root of your problem. Especially with that right angle turn in it. It's not letting the air flow freely enough to get a good draft.

With that size firebox, you should have been able to get that smoker up to a easy 350* , even in those temps. Your intake vent is huge, and if your running with the vents at 3/4 open to get to 300*, that's telling me that it's not letting the air out the other end. I'd like to see a good pic of the opening on the left side of the reverse flow plate, just to see how big that opening is, but I'm sure it's at least twice the size of the exhaust.

So why don't you talk to the builder, explain the problems you are having and tell him that you would like to pay him to redo the exhaust. With the right approach, might get him to do it free or next to nothing.

Once you get the exhaust squared away, the trick for cold weather cooking will be to get that baby up to 400* and get all that steel preheated good before bring the temp back down to where you want it. Then cook at a higher temp than you would on a warm day, say 325 or so,

Yeah, I think you are right. I'll call the builder and explain the problems. Worst comes to worst, I have a friend who has access to a welder. We could mess around with it.

The ribs still turned out great. I had them in the smoker for 45 minutes to start at around 200, put them in the oven for two hours at 250, then finished them in the smoker to harden the rub and glaze BBQ sauce. They had good bark and enough smoke flavor.

The ribs still turned out great. I had them in the smoker for 45 minutes to start at around 200, put them in the oven for two hours at 250, then finished them in the smoker to harden the rub and glaze BBQ sauce. They had good bark and enough smoke flavor.

ribwizzard

Master of the Pit

Just stole this from another thread, but this is a proper stack to cooker ratio

ribwizzard

Master of the Pit

- Jan 6, 2011

- 26,255

- 4,705

I have never been a fan of bends and angles in smoke stacks, also did you ever say how big your opening is at the end of your RF plate ?

I do know the extreme cold can affect your smoker, a friend of mine who does BBQ competitions has experienced this on several occasions. Being from Texas he was not prepared for the big drop in temp. He said he had a really hard time getting his smoker to hold at his cooking temp, he went out and bought a couple of hot water heater blankets to wrap his smoker. Said it helped but still never cooked like he was use to. Last weekend when I did brisket and ribs, when I started the outside temp was 32º but climbed up into the 50's. It took longer for my smoker to come up to temp, because I started it with a chimney full of charcoal, instead of my weed burner, when i use it I go over my racks and inside the CC to help get it up to temp faster. May be a combination of several things

Gary

I do know the extreme cold can affect your smoker, a friend of mine who does BBQ competitions has experienced this on several occasions. Being from Texas he was not prepared for the big drop in temp. He said he had a really hard time getting his smoker to hold at his cooking temp, he went out and bought a couple of hot water heater blankets to wrap his smoker. Said it helped but still never cooked like he was use to. Last weekend when I did brisket and ribs, when I started the outside temp was 32º but climbed up into the 50's. It took longer for my smoker to come up to temp, because I started it with a chimney full of charcoal, instead of my weed burner, when i use it I go over my racks and inside the CC to help get it up to temp faster. May be a combination of several things

Gary

Yeah, I think the cold and the wind were factors in low temps. But I think my main problem was that I couldn't keep the fire going. The sticks wouldn't stay burning unless I kept the firebox door open. I had a hot bed of charcoal and the logs were burning fine on top of the coal with the door open, but as soon as I closed the fb door the logs started smoldering/smoking and not burning. And then my temps would drop. Even with the damper fully open.

Does the problem sound to be an issue with draft? Weird thing is everything burned just fine last weekend. I used seasoned white oak, so I don't think wood is an issue.

The RF plate opening is 0.5 inches on the FB side of the CC and then 3.5 inches opposite the FB. The RF plate is adjustable with a 4" gap, so I can put it in whatever position I want. I like that about the smoker so if I want to have a hot spot for smoking two different kinds of meat I can set the plate accordingly. Where I currently have it set gives me a pretty even temp.

If you guys think it is a good idea, I can talk to the builder or just find another welder and remove the current stack and add a 4" diameter straight stack.

Thanks for all of the help so far in helping me get this thing figured out. I think it can be a great smoker with the right adjustments.

DaveOmak - I know you're an expert. Does my problem still sound like a stack issue?

Does the problem sound to be an issue with draft? Weird thing is everything burned just fine last weekend. I used seasoned white oak, so I don't think wood is an issue.

The RF plate opening is 0.5 inches on the FB side of the CC and then 3.5 inches opposite the FB. The RF plate is adjustable with a 4" gap, so I can put it in whatever position I want. I like that about the smoker so if I want to have a hot spot for smoking two different kinds of meat I can set the plate accordingly. Where I currently have it set gives me a pretty even temp.

If you guys think it is a good idea, I can talk to the builder or just find another welder and remove the current stack and add a 4" diameter straight stack.

Thanks for all of the help so far in helping me get this thing figured out. I think it can be a great smoker with the right adjustments.

DaveOmak - I know you're an expert. Does my problem still sound like a stack issue?

I think if you look at what folks have suggested, and contemplate what is being said, you will come to a conclusion that will make you happy.... There are many very good ideas....

Between the stack and that "valve" in the FB/CC opening.... you have a lot of friction slowing what could be good air flow....

If the builder knew what he was doing when he built the smoker, you wouldn't have any issues.....

There....... I'm on the fence......

Between the stack and that "valve" in the FB/CC opening.... you have a lot of friction slowing what could be good air flow....

If the builder knew what he was doing when he built the smoker, you wouldn't have any issues.....

There....... I'm on the fence......

ribwizzard

Master of the Pit

look at the area of your intake opening vs the area of the exhaust, not even calculating the restriction the elbow causes. Then we all know that air expands when heated. Its like that thing is breathing through a straw.But I think my main problem was that I couldn't keep the fire going. The sticks wouldn't stay burning unless I kept the firebox door open.

Good way to test it, is to leave the cook chamber door open and see if the fire doesnt burn better. If not, then you know its the reverse flow plate openings.

Good idea on burning with the CC door open.

Again, thanks for everyone's help and suggestions. Getting input from this forum is invaluable.

Makes sense that a 3" diameter stack with a 90 degree bend would restrict air flow for a pit that is 36"x20" with a 20"x20" firebox. I'm going to be busy for the next few weekends, but will eventually tinker around with trail and error. And may have a welder put on a new 4" diameter stack. I do understand that the builder obviously didn't understand proper pit dimensions when building the unit, but I think with the right mods to get smooth air flow it will be a great pit for the $$$. I paid $600 for it, so if I can keep it under $800 total including any future mods I'll be happy.

I'll report back in a few weeks.

Again, thanks for everyone's help and suggestions. Getting input from this forum is invaluable.

Makes sense that a 3" diameter stack with a 90 degree bend would restrict air flow for a pit that is 36"x20" with a 20"x20" firebox. I'm going to be busy for the next few weekends, but will eventually tinker around with trail and error. And may have a welder put on a new 4" diameter stack. I do understand that the builder obviously didn't understand proper pit dimensions when building the unit, but I think with the right mods to get smooth air flow it will be a great pit for the $$$. I paid $600 for it, so if I can keep it under $800 total including any future mods I'll be happy.

I'll report back in a few weeks.

Well I smoked some Scarbelly wings tonight, and my temps were pretty consistent around 280*. I did end up removing the FB/CC 'damper' on the smoker, and that really seemed to help get heat into the CC. But I wanted to get to 300* and struggled a little. Maybe next step is to modify the stack. But I'm glad to have made progress already. It was great to get a cook in tonight without having to fight to even get to 225*

By removing the FB/CC damper I had much better heat flow, so clearly it is an air flow issue.

More to come down the road when I can get around to modifying the stack!

By removing the FB/CC damper I had much better heat flow, so clearly it is an air flow issue.

More to come down the road when I can get around to modifying the stack!

I am taking my pit to a local welder tomorrow evening to have the stack modified (or rather replaced). Based on the recommendations from many of you, I have created a design that I think should work for my smoker - pictures below.

Input would be greatly appreciated before I go to the welder, so I can make any last minute adjustments that are needed.

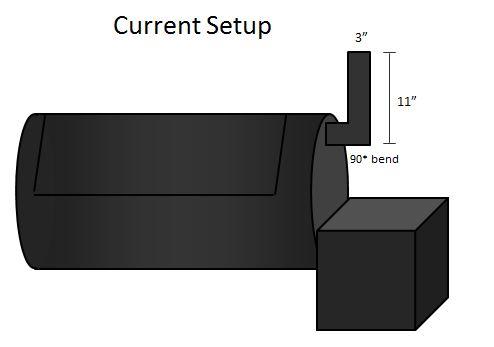

Current setup:

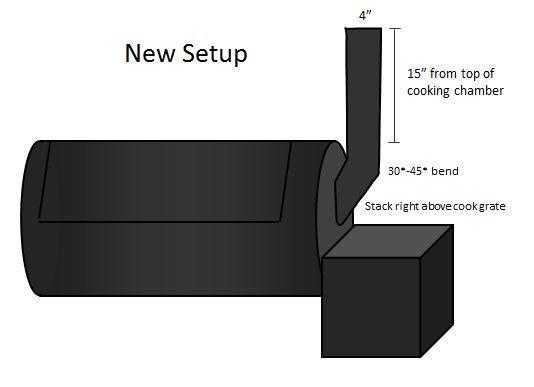

My thoughts are putting a 4" stack on and coming in at around a 30*-45* angle. I think this should create a LOT more airflow vs. a 90* angle.

The stack would be 15" height from the top of the cooking chamber, so it will actually be a longer stack if you include length all the way to the entrance.

My main thought is to get the stack opening right above grate level (much lower than current stack) so the heat is drawn across the grate rather than diagonally across the total cooking chamber to the top right corner where the current stack is. I am having trouble with consistent temp where the RF opening is hotter than the FB side, and I think that lowering the stack entrance would help this. Thoughts?

Input would be greatly appreciated before I go to the welder, so I can make any last minute adjustments that are needed.

Current setup:

My thoughts are putting a 4" stack on and coming in at around a 30*-45* angle. I think this should create a LOT more airflow vs. a 90* angle.

The stack would be 15" height from the top of the cooking chamber, so it will actually be a longer stack if you include length all the way to the entrance.

My main thought is to get the stack opening right above grate level (much lower than current stack) so the heat is drawn across the grate rather than diagonally across the total cooking chamber to the top right corner where the current stack is. I am having trouble with consistent temp where the RF opening is hotter than the FB side, and I think that lowering the stack entrance would help this. Thoughts?

radioguy

Master of the Pit

Anything you can do to lessen that bend will help. Moving the outlet down will allow heat (rises) to stay in CC. Have you considered adding another air intake higher up on the FB? What's the calculator say about smokestack?

RG

RG

RG,

Gary and I were messing around with Feldons calculations through PM this morning, and Feldons suggests a 4"x15" stack. I'll request a 16" given the slight bend, and that would be 16" height from top of CC. When I entered my pit dimensions, I sized the firebox to 100%... And to your point, the idea is to get rid of as much bend as I can.

I also plan to have the stack entrance halfway between the grate level and top of CC.

I have considered adding some additional intake openings on the pit, but will make the decision once I get the stack modified and have a chance to check everything out. Process of elimination and trial and error. My thoughts are that I could *maybe* benefit from having openings both under the grate as well as further up the FB. But we'll see if those are necessary. Those are at least something I can do myself later on without having to weld.

Thanks guys.

Gary and I were messing around with Feldons calculations through PM this morning, and Feldons suggests a 4"x15" stack. I'll request a 16" given the slight bend, and that would be 16" height from top of CC. When I entered my pit dimensions, I sized the firebox to 100%... And to your point, the idea is to get rid of as much bend as I can.

I also plan to have the stack entrance halfway between the grate level and top of CC.

I have considered adding some additional intake openings on the pit, but will make the decision once I get the stack modified and have a chance to check everything out. Process of elimination and trial and error. My thoughts are that I could *maybe* benefit from having openings both under the grate as well as further up the FB. But we'll see if those are necessary. Those are at least something I can do myself later on without having to weld.

Thanks guys.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 10

- Views

- 498

- Replies

- 221

- Views

- 12K

- Replies

- 3

- Views

- 1K

- Replies

- 2

- Views

- 578

- Replies

- 4

- Views

- 1K

- Replies

- 3

- Views

- 954

- Replies

- 14

- Views

- 1K

Hot Threads

-

Our Second piece of Heaven, Little piece on the Atlantic Ocean

- Started by DRKsmoking

- Replies: 55

- General Discussion

-

How Do I Get Rid of These Armadillos?!!

- Started by seenred

- Replies: 39

- Blowing Smoke Around the Smoker.

-

Non fat dried milk

- Started by hog warden

- Replies: 37

- Sausage

-

Getting to the bottom of what happens to cure in smoked sausage

- Started by hog warden

- Replies: 31

- Food Safety

-

Featured A couple thick strips please!