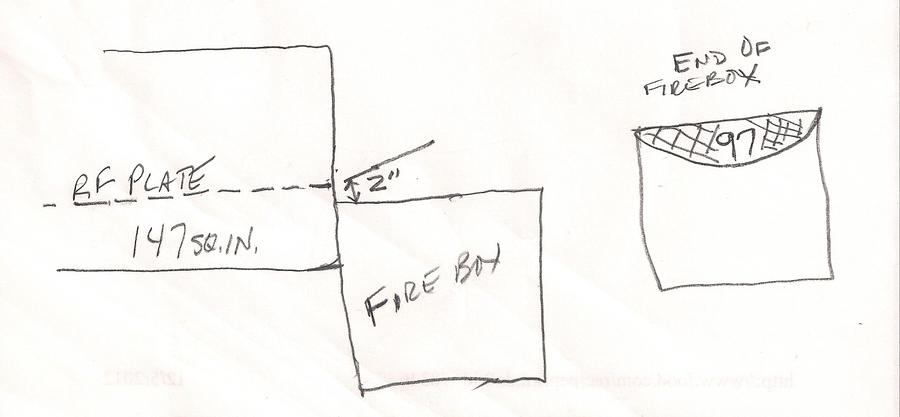

In the Arc calculator, use radius of 12.5".... Segment height (ED) 6.5".... click calculate.... comes up with a segment area 101 sq. in. ..

Very close the the 97" needed for the FB/CC opening... That would be the opening to use....

Now for the RF plate... 97 X 1.5 = 145 sq in... Using 12.5" radius and 8.5" segment height.... segment area is 147 sq in... Perfect for under the RF plate.... You can lower the RF plate if you need the room...

Then the bottom cook rack 2" above the RF plate leaves 14" clearance for the second rack...

First build

- Thread starter berry1611

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Thanks Dave, I think I might have a handle on it now. I thought the opening from the firebox to the cook chamber had to be the same size in sq. inches as the area at the end and under the RF plate. At the opening for the firebox to cooking chamber is smaller (bottle necked). I did the cal. and it was showing a 15.75" diameter for half moon and 11.10" diameter for a round (circular) opening. I found a 11.5" diameter bowel in the house and drew a circle with it as you will see in the upload photo's to follow. I then took a rope and made tit o that size 11.5", then shaped the rope into a half moon shape: it came out to be 15.75" diameter across the top. See, I was trying to make the opening from the firebox to cooker all the way out to the edge, as indicated in the red lined area in the photo. The blue lined area would be 2" above the opening and the RF plate is the blue horizontal line. The other markings can be ignored. Do I have it or am I still missing the boat.

Brian, morning..... You are correct in your drawing.... There is an easier way to get the right size opening and it will give more room for cook racks....

The tank opening is the diameter you want on the firebox... Draw a 25" diameter circle on a piece of paper, (or the dia. of the cook chamber).. Measure up 6.5" from the edge of the circle... Draw line (AB green area)... Cut it out with a scissors and place it on the firebox where you want the opening... At this point you need to decide if you are inserting the firebox into the cook chamber and using the top of the firebox for part of the RF plate (you will need to lower the opening 1 1/2 - 2" from the top of the firebox) or mounting the firebox on the end of the smoke chamber).... Now you have a cutout that fits the cook chamber perfectly... No wasted area to consume valuable room in the smoker... You can have the FB inserted into or flush with the end of the cook chamber as SQWIB suggested, (for some very good reasons)....

Once that is done, it is important to think of the remaining steps in the build.... cutting the cook chamber for the firebox or not..... The install height of the RF plate... the drain... cook rack placement... exhaust stack placement (top or end).... Door placement... Hinges... Figure the sequence these will happen so you don't get in a pickle with other steps....

Hope I understood your question correctly and didn't go off on some stupid tangent and what I wrote makes sense.... Dave

The tank opening is the diameter you want on the firebox... Draw a 25" diameter circle on a piece of paper, (or the dia. of the cook chamber).. Measure up 6.5" from the edge of the circle... Draw line (AB green area)... Cut it out with a scissors and place it on the firebox where you want the opening... At this point you need to decide if you are inserting the firebox into the cook chamber and using the top of the firebox for part of the RF plate (you will need to lower the opening 1 1/2 - 2" from the top of the firebox) or mounting the firebox on the end of the smoke chamber).... Now you have a cutout that fits the cook chamber perfectly... No wasted area to consume valuable room in the smoker... You can have the FB inserted into or flush with the end of the cook chamber as SQWIB suggested, (for some very good reasons)....

Once that is done, it is important to think of the remaining steps in the build.... cutting the cook chamber for the firebox or not..... The install height of the RF plate... the drain... cook rack placement... exhaust stack placement (top or end).... Door placement... Hinges... Figure the sequence these will happen so you don't get in a pickle with other steps....

Hope I understood your question correctly and didn't go off on some stupid tangent and what I wrote makes sense.... Dave

chinasmoke

Smoke Blower

I agree with Dave the way you have it laid out on your picture you are wasting a lot of space with in your chamber.

Here are a few pics of my opening but i used an old propane tank, that's why it's inserted into the chamber. Keep your opening low to conserve space for a second rack

Here are a few pics of my opening but i used an old propane tank, that's why it's inserted into the chamber. Keep your opening low to conserve space for a second rack

I agree with you that the opening needs to be smaller and low. The white piece of paper is roughly 24.75" diameter. The red area was squared out to 102sq in. and I thought it seemed too big of an area. The rope that is in the red area was place there to show the actual opening size: it will be moved to the lowest point. Now once inside the cook chamber under the RF plate and at the end of the RF plate that area needs to be roughly 147sq in. opening. The red and blue area represents the 147sq inches, that is 1 1/2 area Dave spoke about. The blue line would be the RF plate. Am I right or do I need to lower the RF plate (the blue line)?

I am going to butt the firebox up to the end not insert the firebox into the chamber. ON the firebox, do I need a gap from the top or can I place the top of the moon shape all the way at the top edge. Now on the smoke stack do I bring it into the cook chamber just a few inches from the bottom rack or just flush at the point it enters the chamber? The space between the racks seem to be an average of 5 to 6 inchs per other post I have read and the space between the RF plate and the bottom rack was suggested to be 4 to 6 inches, is this all correct?

Thank you all for your info and photo's and please keep them coming.

I am going to butt the firebox up to the end not insert the firebox into the chamber. ON the firebox, do I need a gap from the top or can I place the top of the moon shape all the way at the top edge. Now on the smoke stack do I bring it into the cook chamber just a few inches from the bottom rack or just flush at the point it enters the chamber? The space between the racks seem to be an average of 5 to 6 inchs per other post I have read and the space between the RF plate and the bottom rack was suggested to be 4 to 6 inches, is this all correct?

Thank you all for your info and photo's and please keep them coming.

Please excuse the crude drawings.

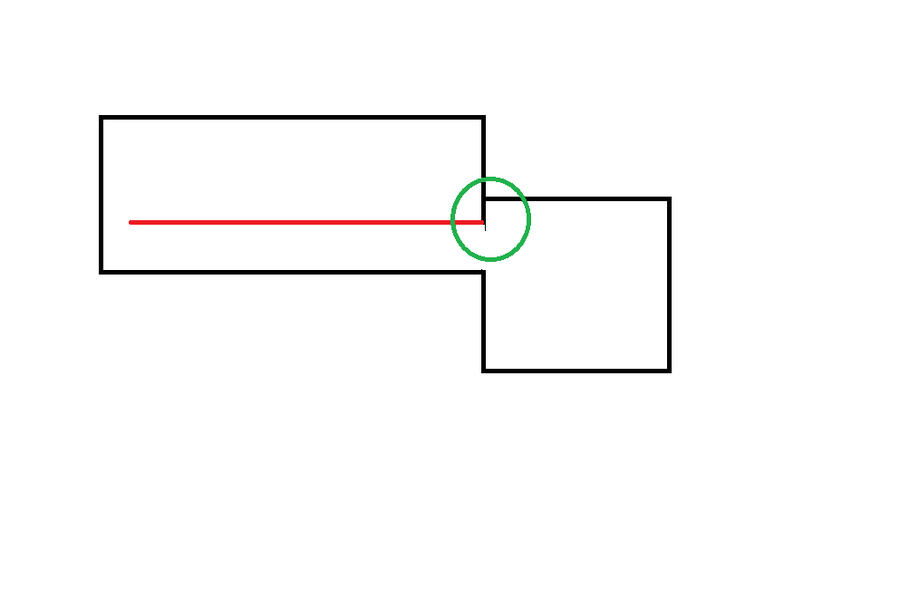

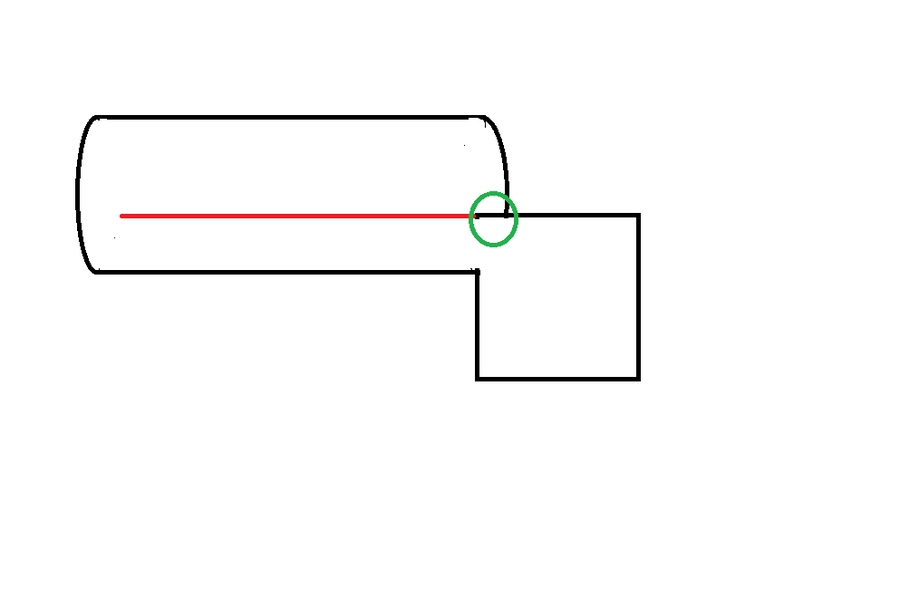

The green circle represents where you will get excessive radiant heat mine was at a 50 -75 degree difference at 300+ plus degrees, that's why I installed the 2 baffles, however I believe that the reason my pit can get fairly hot is because of this Diffused "HeatHammering effect" with the baffle plates.

I am not sure which would work the best but I would have choosen the first style if I could have, but as I said earlier I think I benefited from the heat hammering the top of the firebox(the part inside the smoke chamber) AFTER I ADDED THE DIFFUSEER/BAFFLE PLATES

Here is a test I ran with the baffles.

Once the pit is heated up I get 5 - 15 degree variance at 225-275 degrees, I can live with that,

The green circle represents where you will get excessive radiant heat mine was at a 50 -75 degree difference at 300+ plus degrees, that's why I installed the 2 baffles, however I believe that the reason my pit can get fairly hot is because of this Diffused "HeatHammering effect" with the baffle plates.

I am not sure which would work the best but I would have choosen the first style if I could have, but as I said earlier I think I benefited from the heat hammering the top of the firebox(the part inside the smoke chamber) AFTER I ADDED THE DIFFUSEER/BAFFLE PLATES

Here is a test I ran with the baffles.

Once the pit is heated up I get 5 - 15 degree variance at 225-275 degrees, I can live with that,

chinasmoke

Smoke Blower

I had the same issue with excessive heat until I installed a baffle similar to what Dave had posted earlier

I would deffinatly not install the stack way in the chamber. I did that at first and had to cut it out , way too much smoke and follow the stack length closely. I had mine a little too long and the smoker ran hot and inconsistent.

I would deffinatly not install the stack way in the chamber. I did that at first and had to cut it out , way too much smoke and follow the stack length closely. I had mine a little too long and the smoker ran hot and inconsistent.

This is an explanation for the first paragraph.... about the 97 and 147 sq in areas... DaveI agree with you that the opening needs to be smaller and low. The white piece of paper is roughly 24.75" diameter. The red area was squared out to 102sq in. and I thought it seemed too big of an area. The rope that is in the red area was place there to show the actual opening size: it will be moved to the lowest point. Now once inside the cook chamber under the RF plate and at the end of the RF plate that area needs to be roughly 147sq in. opening. The red and blue area represents the 147sq inches, that is 1 1/2 area Dave spoke about. The blue line would be the RF plate. Am I right or do I need to lower the RF plate (the blue line)?

I am going to butt the firebox up to the end not insert the firebox into the chamber. Good choice

ON the firebox, do I need a gap from the top or can I place the top of the moon shape all the way at the top edge.

Place the moon shape all the way to the top of the end of the firebox...

Now on the smoke stack do I bring it into the cook chamber just a few inches from the bottom rack or just flush at the point it enters the chamber? Lower the stack near the bottom rack....

The space between the racks seems to be an average of 5 to 6 inchs per other post I have read... Spacing is subjective... What are you going to cook.... Turkeys need more than 6".... Butts could use 7"... That is if the lower rack slides out.... If it doesn't, more room is needed... Does the top rack slide out also.... So many variables to think of.... Are there 2 top racks so turkeys, butts and ABT's can be cooked at the same time...

and the space between the RF plate and the bottom rack was suggested to be 4 to 6 inches, is this all correct? All you need is air/smoke/heat flow ... Some folks smokers first rack is 3" above the RF plate.... The builder/owner has to decide when it comes to the hair splitting....

Thank you all for your info and photo's and please keep them coming.

Last edited:

Ok, it is lined up now in my head. Thanks Dave, ChinaSmoke and SQWIB. I hope to cut the metal for the firebox this coming week. I will post pics throughout the build. Thanks again guys.

Brian, evening.... Cool.... Glad it all came together.... Now that you are "in tune" I'll add one more idea..... My thoughts are to have the RF plate removable... Line it up and set it in place.... tack weld 2 places in the middle... if you ever want to change the design, add a drain, add a plate under it, by the fire box, to reduce the heat at the FB end.... If you put a drain in the RF plate, stub in a pipe that slips into the drain line that goes to the valve... I always plan for unknown stuff.... anal about that type of thing.. If I can think of more stuff to help you get confused, I will surely contact you.... HAHAHAHA .. Dave

Last edited:

jabbo

Meat Mopper

Correct me is I am wrong, but wouldn't making the RF plate a water pan with about 2-3 inches of water even out the temps much better than those baffles? Not to mention a ton easier to install. If it doesn't work, you could always add the baffle later. I would go for the easiest and least costly method first. The water may boil out but adding more water isn't difficult. The water will remain 212 degrees until it is gone so no excess heat should get through it. It also helps keep the meat moist and has been shown to aid the smoke getting into the meat. Where am I going wrong here?

chinasmoke

Smoke Blower

RF plate acts as even radiant heat and steam once the drippings hit the plate. Imo thats the advantage or rf vs. side. by adding water it will probably cool the chamber down and making it inefficient. There is only one real hot spot just in that corner

Hello Dave, I am confused on the drain. I am plainning on installing a drain in the RF plate now. The confusion is, ("stub in a pipe that slips into the drain line that goes to the valve") I can not picture that, so here we go again. You are going to have to draw a picture of this one.

I was going to do my drain something like this the install my RF plates.I also thought about putting a drain in the bottom of the cook chamber for any liquid that might get in that area from cleaning.

I was going to do my drain something like this the install my RF plates.I also thought about putting a drain in the bottom of the cook chamber for any liquid that might get in that area from cleaning.

jabbo

Meat Mopper

China, I have thought the same thing about water cooling the CC, but have since learned that once the water heats up, the air temp continues to rise to the desired temp. While the RF plate is a good shield from the radiant heat, the water is better and has the additional advantage of dispersing the heat over throughout it's entire volume. No matter how hot the plate gets, the water will not rise above 212 degrees. Since the water will span the entire length of the grate, it will completely shield the meat from radiant heat, thereby, only allowing the convection heat to enter the CC via the end of the plate with the smoke. The science is sound, by only doubts are if the heat rounding the plate with the smoke is the sufficient. Sorry, I didn't mean to high jack the thread.

Brian, morning.... This has been an idea floating around in the gray matter area for awhile.... Hasn't been put into practice that I know of...

The drawback appears to be the RF drain has to be open all the time.... Water, for steam, will have to be put in a baking pan of sorts... I don't think that would be a major deal.... Seems this "steaming meat in a smoker" idea has exploded into some ritual.... I don't do it...

A well designed RF smoker will control the temp perfectly... Temp swings from opening the door are normal and expected... Thermal mass will help with reducing swings in temp... The RF plate does not need to be perfectly air tight... The area at the end of the plate will be the preferred air flow path.... I think a removable plate would be the cat's ###... The RF plate "V shape" could be done at the shop in a press brake... 2-3 degree bend "V" would be enough to get the grease moving to the center toward the drain..

Click on pic to enlarge

The drawback appears to be the RF drain has to be open all the time.... Water, for steam, will have to be put in a baking pan of sorts... I don't think that would be a major deal.... Seems this "steaming meat in a smoker" idea has exploded into some ritual.... I don't do it...

A well designed RF smoker will control the temp perfectly... Temp swings from opening the door are normal and expected... Thermal mass will help with reducing swings in temp... The RF plate does not need to be perfectly air tight... The area at the end of the plate will be the preferred air flow path.... I think a removable plate would be the cat's ###... The RF plate "V shape" could be done at the shop in a press brake... 2-3 degree bend "V" would be enough to get the grease moving to the center toward the drain..

Click on pic to enlarge

Brian, morning.... This has been an idea floating around in the gray matter area for awhile.... Hasn't been put into practice that I know of...

The drawback appears to be the RF drain has to be open all the time.... Water, for steam, will have to be put in a baking pan of sorts... I don't think that would be a major deal.... Seems this "steaming meat in a smoker" idea has exploded into some ritual.... I don't do it...

A well designed RF smoker will control the temp perfectly... Temp swings from opening the door are normal and expected... Thermal mass will help with reducing swings in temp... The RF plate does not need to be perfectly air tight... The area at the end of the plate will be the preferred air flow path.... I think a removable plate would be the cat's ###... The RF plate "V shape" could be done at the shop in a press brake... 2-3 degree bend "V" would be enough to get the grease moving to the center toward the drain..

Click on pic to enlarge

I like where your going with this........

You could almost use the "hot spot" above the fire box for the water pan if needed.....I am not a huge fan of the water smokers.....

Ok, now my gray matter is starting to move. You are saying to place your pipe and valve solid but with the removable RF plate make it out of one peace of metal and wield a stub pipe that would insert into the main pipe and valve. Yes, I could not do that with the design that I posted. I have no desire of putting water on the RF plate to steam while smoking. Your idea could be done, by wielding the pipe at the RF plate that extends through the bottom of the cook chamber, (all one piece). Just wield a flange on the pipe at the area where the drain pipe makes contact with the inside bottom just before it exits the bottom of the smoker. Then thread the pipe below the outside; screw on a nut then screw on your valve. If plate needs to be removed undo valve, nut, tack wields and maneuver plate out. If pipe needs to be longer add extension on lower outside portion and then valve.

If doing a removable RF plate that is a good thought you had Dave. That would be a pain to cut and have to re-wield that drain pipe.

If doing a removable RF plate that is a good thought you had Dave. That would be a pain to cut and have to re-wield that drain pipe.

jabbo

Meat Mopper

Dave, that is a great idea. I believe someone on this forum has already done it. I remember seeing it somewhere and thinking it was simply brilliant. I don't know why it is not common place. I don't remember whose build it was but I am pretty sure it was in this forum.

Berry, I think you have just about all of your bases covered. I can't wait to see how you put it all together. these things are pretty much the same but everyone does it differently. I really enjoy that aspect of this forum. I'm looking forward to your twist on things.

Berry, I think you have just about all of your bases covered. I can't wait to see how you put it all together. these things are pretty much the same but everyone does it differently. I really enjoy that aspect of this forum. I'm looking forward to your twist on things.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 35

- Views

- 1K

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 373

- Replies

- 33

- Views

- 1K

- Replies

- 5

- Views

- 2K

- Replies

- 230

- Views

- 12K

Hot Threads

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 65

- Blowing Smoke Around the Smoker.

-

Questions for RecTeq owners

- Started by schlotz

- Replies: 64

- Blowing Smoke Around the Smoker.

-

Lost my dad yesterday

- Started by normanaj

- Replies: 40

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 35

- Sausage

-

Took a stroll this afternoon

- Started by Buckeyedude

- Replies: 33

- Field and Stream