- Dec 19, 2010

- 76

- 15

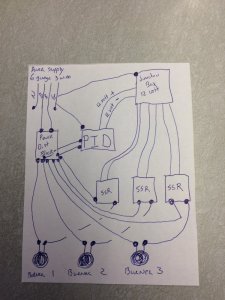

I have a bit of an issue. Some background first. I've build 2 Pid smokers and am now working on the 3rd for my cousin. One was 120v 1500 watts and the other was 240v at 4600 watts. They run great no problems at all. He went big so here is what I did, 1 pid, a disturbution block, 3 25amp SSR(one for each burner), 3 2600 watt burners, used 10 gauge high temp oven wire inside the box all the way to the relays and block. The problem- He lined his smoker box with stainless, when I touch the metal I can feel a current like its energized when the pid is putting power to the burners. I've checked all my wiring and none are bare or cut. He does have the burners mounted to an angle that is mounted to the stainless, but I don't see any issues with it( mine are mounted the same) the wires are all coming through 1- 1" hole and are bundled along the angle till they reach each burner. Is them bundled the problem? Should I have a ground run to the inside of the box? Any help or suggestion would be appreciated