Hi - just finished prototyping my new curing chamber controlled by Raspberry Pi and using Google Sheets as GUI. I plan on a full build writeup soon.

Question - the humidity fluctuates by around 15% but the average is still close to my desired setpoint. Is this an issue?

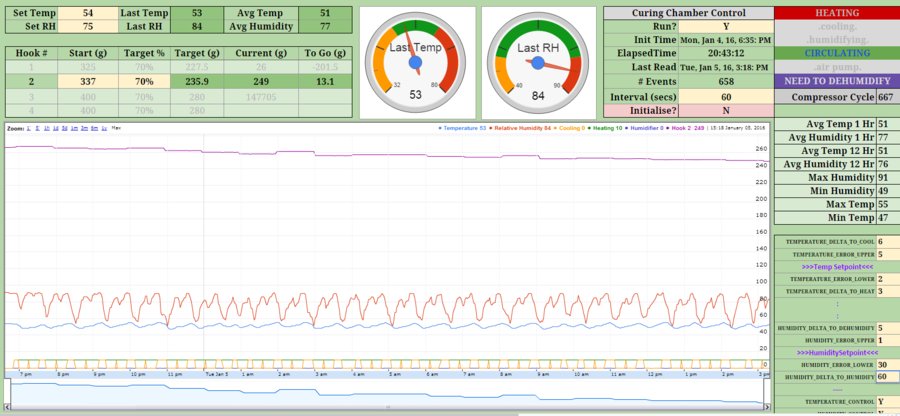

The red line in the below is the RH (excuse the messy prototype GUI!).

Question - the humidity fluctuates by around 15% but the average is still close to my desired setpoint. Is this an issue?

The red line in the below is the RH (excuse the messy prototype GUI!).