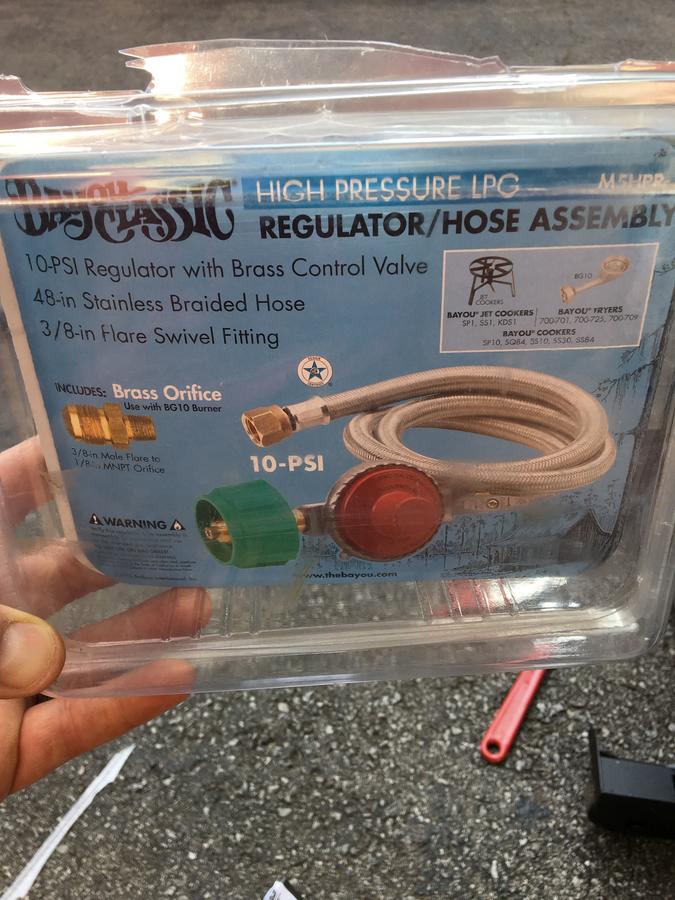

Hi guys, Kind of a double post as I just mentioned this in another thread I started so sorry about that. Anyway, I'm in the process of installing a Bayou Classic regulator with a needle valve to my Masterbuilt Dual Fuel. It comes with a replacement brass orifice that has a smaller hole than the stock one. However, the threads are a tad longer. Do I want the newer orifice installed? Or keep the original one with the bigger hole?

Last question? When removing the orifice, it seems like there's some kind of thread seal/tape like Loc-Tite. Anyone know what that would be? Thanks

Last question? When removing the orifice, it seems like there's some kind of thread seal/tape like Loc-Tite. Anyone know what that would be? Thanks