I decided to make a batch of jerky based on the success I had a year or so ago making some using the recipe offered by Couger78 in this thread:

http://www.smokingmeatforums.com/t/138397/beef-jerky-ten-pounds-two-types-with-pics

That came out great, and we all had a hankerin' for another batch.

I found some reasonably priced eye of round "steaks" at the local Sam's Club and got three packages. After trimming off the fat, slicing it, and cutting out any big streaks of it in the strips, I ended up with about 10.9 lbs of ready-to-go meat.

I used the exact "pepper" recipe from Cougar78 in that thread.

I then used a FoodSaver to seal it into a very large bag with pretty much all of the air removed. I let that sit in the fridge for a bit more than 48 hours.

I then tediously hung it all using toothpicks to hold three strips each, and hanging from two of the racks for the MES-40. That was a very long process!

As I finished each rack, I put it into the smoker, set to 160° to get a head start on the drying phase. An hour after putting in the 2nd rack, I checked, and it was still pretty wet. So I gave it another hour of "pre-drying". Then I lit the AMNPS with a couple of rows of Pitmaster's Choice pellets.

I let it go for about three hours, and when I checked, only about half of the pellets had burned, and the jerky was still pretty moist. It had started raining, so I put a plastic tub over the electronics in case the rain decided to blow in under the eave of the house (so far, I'd been lucky and that part of the smoker hadn't gotten wet).

Measuring near where the air comes up out of the vent, I could see that the temperature wasn't as high there as what I'd have liked. But I re-lit the pellets and gave it a few more hours.

At that point, I checked, and the pellets were out again, but really, it had gotten plenty of smoke. However, the jerky was still too moist.

So I gave it a while longer, and it didn't seem to me that it was making much progress. Looking at how things were running, I put a separate temperature probe into some various places in the smoker and allowed things to come to equilibrium. Based on that, I figured out that the temperature wasn't as high anywhere in the smoker as the setpoint. That was actually not all that unexpected. With a lot of wet meat surface area, and with the controller's temperature probe down low in the smoker, just above the heating element, it was bound to overestimate the average temperature in the areas where the meat was located.

I also realized that at this sort of low temperature setting, there isn't much draw or draft being induced. And with low airflow, there would be poor mixing and particularly uneven temperatures.

I usually run the MES-40 with the chip hopper completely out, the top vent all the way open, and the chip burner pulled open as well. Running at the usual meat cooking/smoking temperatures around 225°, the unit draws well, the pellets in the AMNPS burn well, and things come out dandy. My MES is what I believe we were calling the new-style 1st generation MES, with the vent on the top. I don't ever use the water pan, and have things set up to force the smoke to flow where I want it to go using foil baffles in a couple of places. It works well. You can see the basic air/smoke flow regime in the top photo I posted.

But anyhow, for this low temperature operation, and realizing that what I really need for jerky is not only a smoker, but a dehydrator, I decided that some forced air was probably appropriate. :)

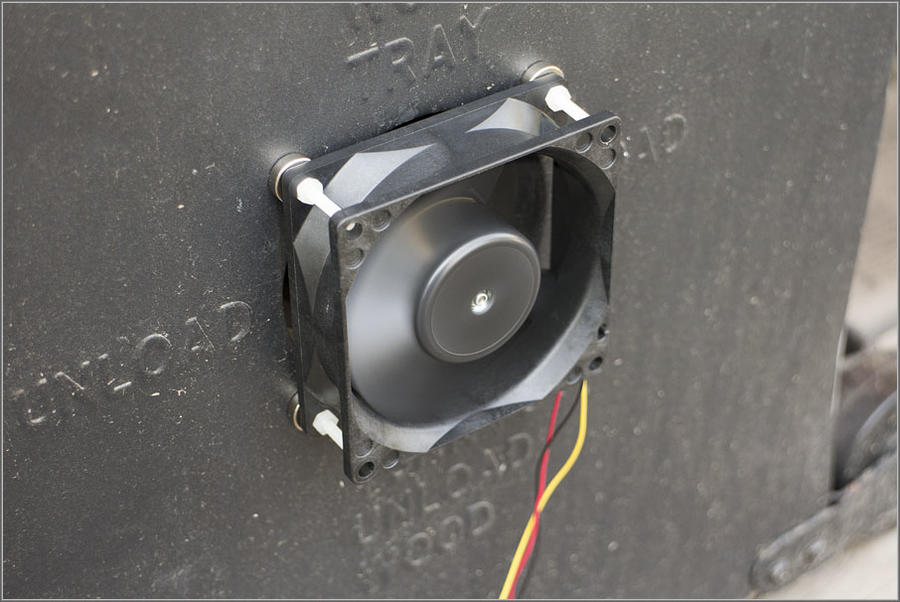

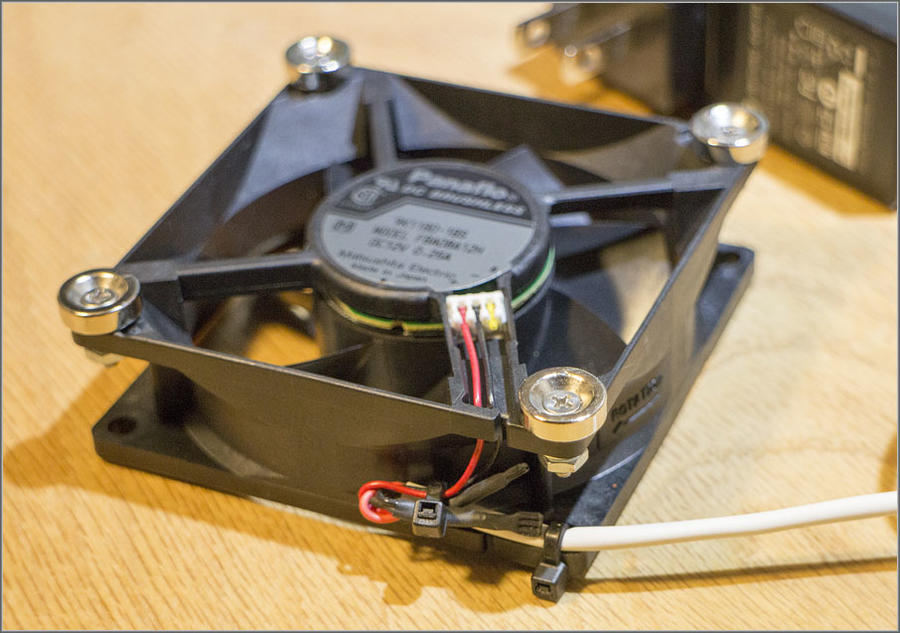

So I got a small computer fan from my stash, bolted on four small rare-earth magnets, and scrounged up a small wall-cube power supply from my junk collection, and got the wiring kludged together so I could use it right away. The magnets allowed me to just stick the fan over the air inlet/chip loader hole, and get a pretty good air flow through the smoker.

In two hours, the jerky was right where I wanted it for dryness!

Also, the temperatures everywhere in the smoker were all the same. Extremely even. And what sort of surprised me was that the heating element was switching on and off at about a 40% duty cycle. I had expected that all of that air flow might have been too much, and the heater would struggle to keep the temperature at 160°.

Since this arrangement was blowing the air right in over the heating element, and then that air has to move through my maze of foil baffles, etc., it really did give the system an amazingly uniform temperature throughout the whole area. And with that reasonable air flow, the dehydration effect was excellent.

The jerky came out great despite the difficulties I had during most of the run. And I learned a LOT.

I rewired the fan and remounted the magnets better, and I plan on using it especially for future jerky runs, but also to force better air flow at other times. The way I figure it, I can stick the fan directly over the air inlet for the dehydration phases of jerky-making, and slide it off to one side more or less to get just the desired airflow for the smoking phase of jerky-making or even during other smoking processes. It'll be a handy tool to have in the arsenal.

So this might be an idea that will work for other people and different kinds of smokers as long as you've got an air inlet that you can stick the magnetic fan over when needed.

http://www.smokingmeatforums.com/t/138397/beef-jerky-ten-pounds-two-types-with-pics

That came out great, and we all had a hankerin' for another batch.

I found some reasonably priced eye of round "steaks" at the local Sam's Club and got three packages. After trimming off the fat, slicing it, and cutting out any big streaks of it in the strips, I ended up with about 10.9 lbs of ready-to-go meat.

I used the exact "pepper" recipe from Cougar78 in that thread.

I then used a FoodSaver to seal it into a very large bag with pretty much all of the air removed. I let that sit in the fridge for a bit more than 48 hours.

I then tediously hung it all using toothpicks to hold three strips each, and hanging from two of the racks for the MES-40. That was a very long process!

As I finished each rack, I put it into the smoker, set to 160° to get a head start on the drying phase. An hour after putting in the 2nd rack, I checked, and it was still pretty wet. So I gave it another hour of "pre-drying". Then I lit the AMNPS with a couple of rows of Pitmaster's Choice pellets.

I let it go for about three hours, and when I checked, only about half of the pellets had burned, and the jerky was still pretty moist. It had started raining, so I put a plastic tub over the electronics in case the rain decided to blow in under the eave of the house (so far, I'd been lucky and that part of the smoker hadn't gotten wet).

Measuring near where the air comes up out of the vent, I could see that the temperature wasn't as high there as what I'd have liked. But I re-lit the pellets and gave it a few more hours.

At that point, I checked, and the pellets were out again, but really, it had gotten plenty of smoke. However, the jerky was still too moist.

So I gave it a while longer, and it didn't seem to me that it was making much progress. Looking at how things were running, I put a separate temperature probe into some various places in the smoker and allowed things to come to equilibrium. Based on that, I figured out that the temperature wasn't as high anywhere in the smoker as the setpoint. That was actually not all that unexpected. With a lot of wet meat surface area, and with the controller's temperature probe down low in the smoker, just above the heating element, it was bound to overestimate the average temperature in the areas where the meat was located.

I also realized that at this sort of low temperature setting, there isn't much draw or draft being induced. And with low airflow, there would be poor mixing and particularly uneven temperatures.

I usually run the MES-40 with the chip hopper completely out, the top vent all the way open, and the chip burner pulled open as well. Running at the usual meat cooking/smoking temperatures around 225°, the unit draws well, the pellets in the AMNPS burn well, and things come out dandy. My MES is what I believe we were calling the new-style 1st generation MES, with the vent on the top. I don't ever use the water pan, and have things set up to force the smoke to flow where I want it to go using foil baffles in a couple of places. It works well. You can see the basic air/smoke flow regime in the top photo I posted.

But anyhow, for this low temperature operation, and realizing that what I really need for jerky is not only a smoker, but a dehydrator, I decided that some forced air was probably appropriate. :)

So I got a small computer fan from my stash, bolted on four small rare-earth magnets, and scrounged up a small wall-cube power supply from my junk collection, and got the wiring kludged together so I could use it right away. The magnets allowed me to just stick the fan over the air inlet/chip loader hole, and get a pretty good air flow through the smoker.

In two hours, the jerky was right where I wanted it for dryness!

Also, the temperatures everywhere in the smoker were all the same. Extremely even. And what sort of surprised me was that the heating element was switching on and off at about a 40% duty cycle. I had expected that all of that air flow might have been too much, and the heater would struggle to keep the temperature at 160°.

Since this arrangement was blowing the air right in over the heating element, and then that air has to move through my maze of foil baffles, etc., it really did give the system an amazingly uniform temperature throughout the whole area. And with that reasonable air flow, the dehydration effect was excellent.

The jerky came out great despite the difficulties I had during most of the run. And I learned a LOT.

I rewired the fan and remounted the magnets better, and I plan on using it especially for future jerky runs, but also to force better air flow at other times. The way I figure it, I can stick the fan directly over the air inlet for the dehydration phases of jerky-making, and slide it off to one side more or less to get just the desired airflow for the smoking phase of jerky-making or even during other smoking processes. It'll be a handy tool to have in the arsenal.

So this might be an idea that will work for other people and different kinds of smokers as long as you've got an air inlet that you can stick the magnetic fan over when needed.

Last edited: