- Mar 20, 2016

- 7

- 10

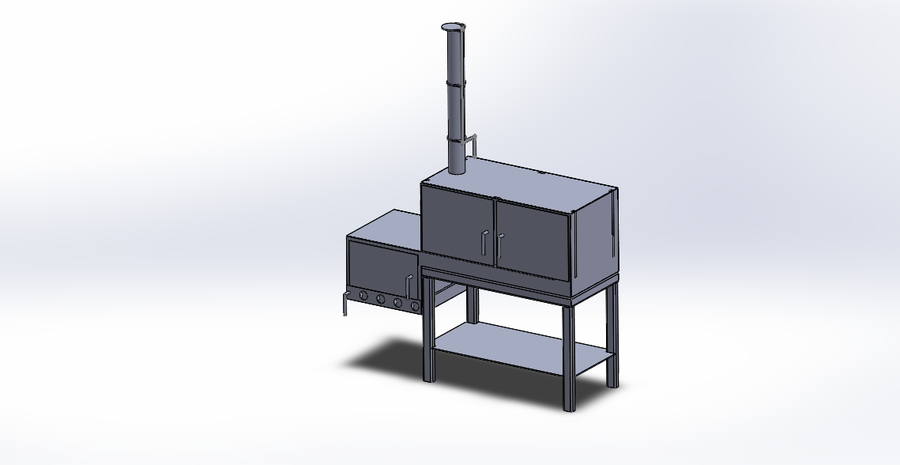

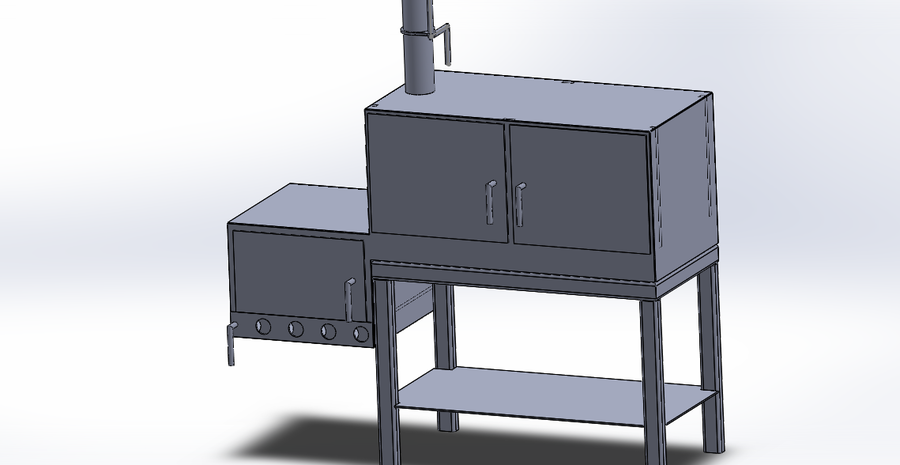

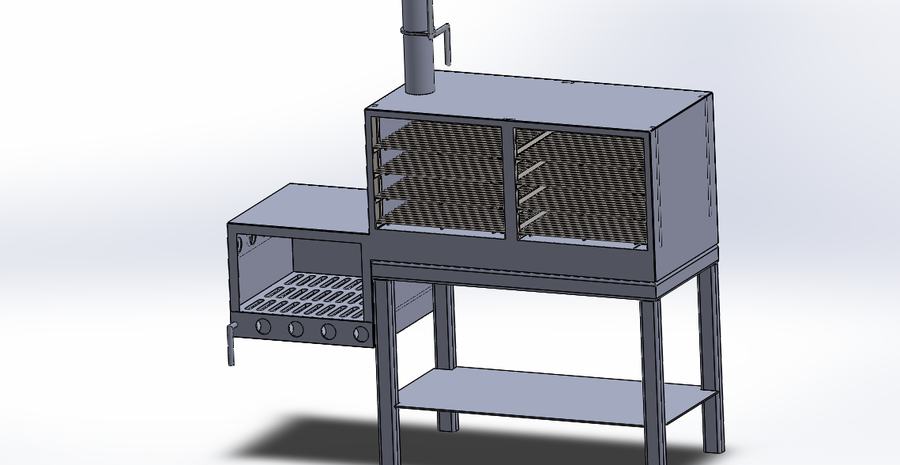

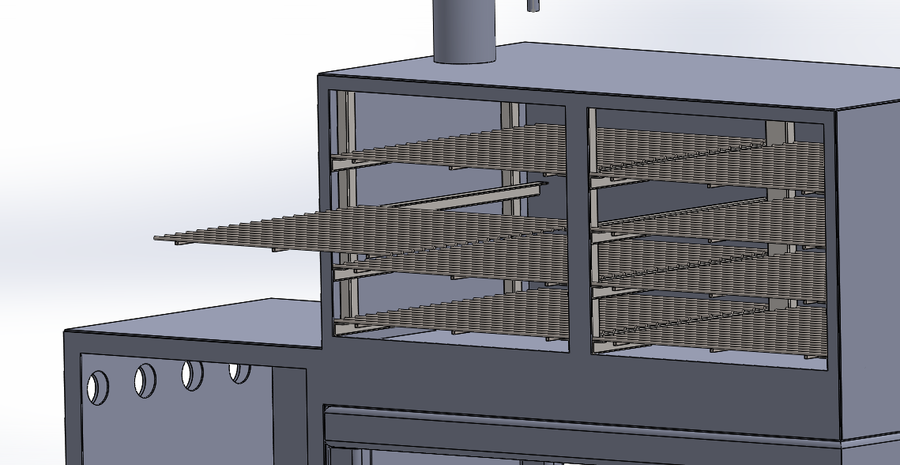

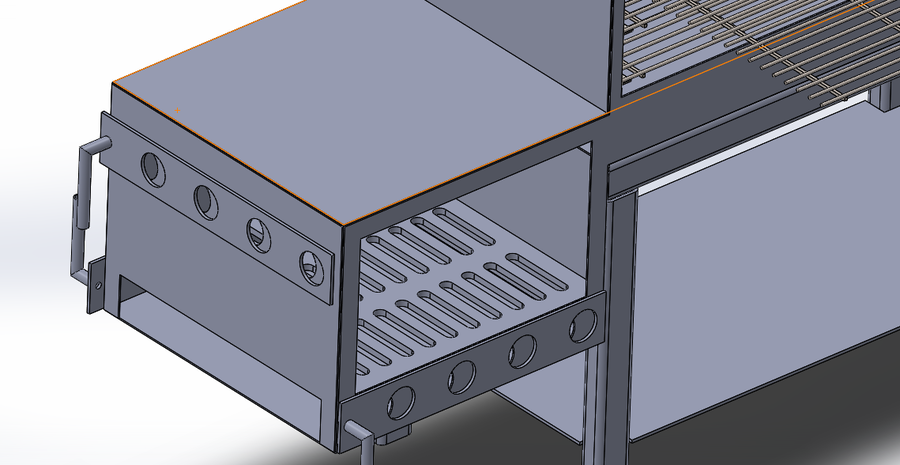

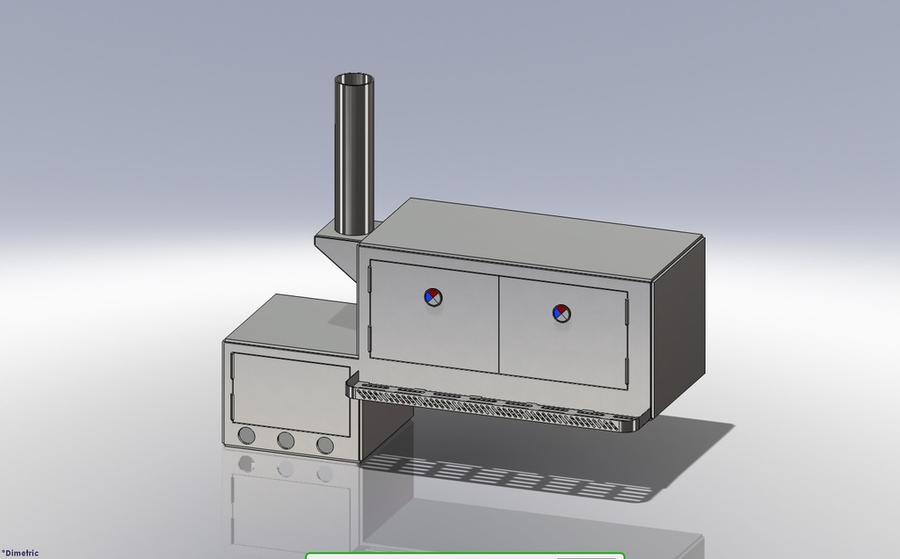

I am about to start building a reverse flow, I started the drawings last night. Please critique away.

All calculations here:

http://feldoncentral.com/bbqcalcula...27&fi=0,0,2.5,31.10,6.34&fc=10.28,14.53,82.94

All calculations here:

http://feldoncentral.com/bbqcalcula...27&fi=0,0,2.5,31.10,6.34&fc=10.28,14.53,82.94