fighting irish

Newbie

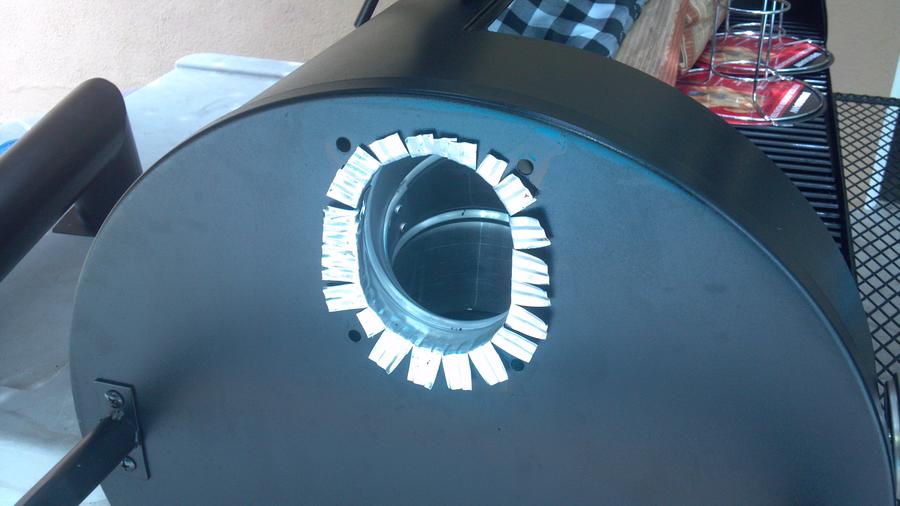

Just got my trailmaster in today and plan on putting together this weekend. Does anyone know if I can get that Rutlands silicone in Home Depot or lowes? Also I might néed some more pics on that deflector shield and bottom plates that have been mentioned. Also how do you season this grill.