- Mar 16, 2015

- 252

- 81

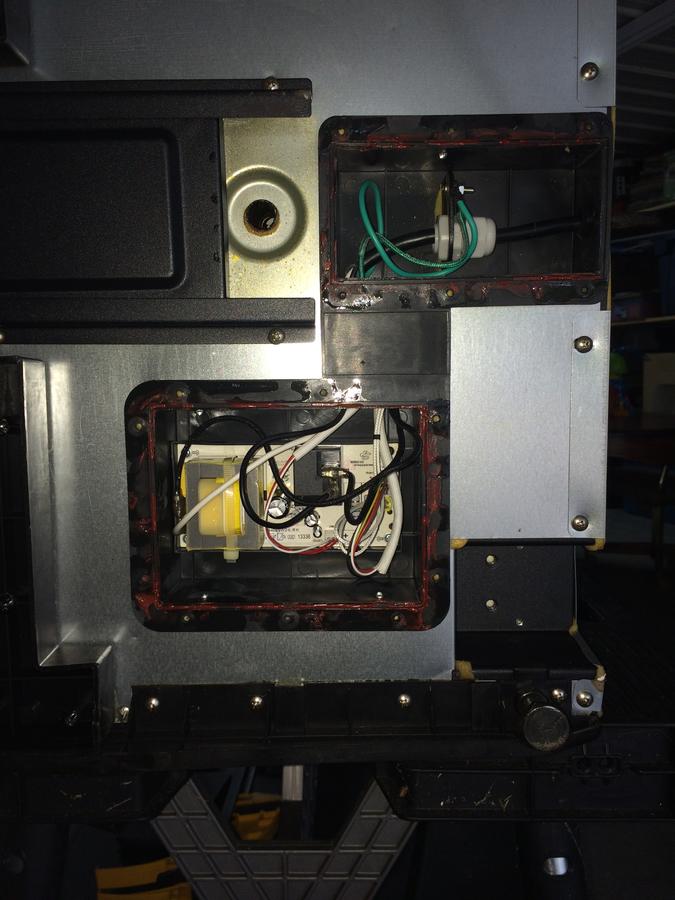

I have a 2nd generation 40" 1200W Masterbuilt smoker that I would like to connect to a Auber PID controller since I'm not happy with the wide temp swings I'm getting. I know that the PID needs to be connected per Auber instructions as shown here ()

My two questions are:

When rewiring the Masterbuilt do I keep the Masterbuilt temperature limit cutoff switch in or do I eliminate that also?

I use my Masterbuilt for low temp smoking for making smoked sausage, snack sticks, jerky and bacon. I am not concerned with the Masterbuilt chip loader producing smoke as I use a AMNPS. The PID controllers I have been looking at for the Masterbuilt are:

WS-1510ELPM (multi purpose)

WS-1510DPMS (K type thermocouple)

WS-1211GP (single sensor)

WSD-1200GPH (dual probe).

Is one better then the other for the application that I mentioned in the top of the paragraph?

Thanks in advance for any help in the matter.

My two questions are:

When rewiring the Masterbuilt do I keep the Masterbuilt temperature limit cutoff switch in or do I eliminate that also?

I use my Masterbuilt for low temp smoking for making smoked sausage, snack sticks, jerky and bacon. I am not concerned with the Masterbuilt chip loader producing smoke as I use a AMNPS. The PID controllers I have been looking at for the Masterbuilt are:

WS-1510ELPM (multi purpose)

WS-1510DPMS (K type thermocouple)

WS-1211GP (single sensor)

WSD-1200GPH (dual probe).

Is one better then the other for the application that I mentioned in the top of the paragraph?

Thanks in advance for any help in the matter.

Last edited: