- Feb 22, 2015

- 82

- 11

Update with Tips Below

Responded to an ad on Craigslist list & initially turned him down because I thought it was to small. Well he contacted me at the beginning of the week saying that his wife wanted it gone & he would give it to me for free. How could I say no?? So I picked it up on my way to an estate sale.

From what I can garner in my quick research online, it is a 1948 GM Frigidaire. I ordered an Auber PID, Brinkmann 1500 watt element. I also picked up a 3" exhaust with rain cap, some stainless steel rivets.

I'm wondering if I plan to do 1" steel intake into a AMPS ammo box, will that be enough of air intake? There isn't a damper on the exhaust, figured I would add a 2nd intake with damper if i needed more control, but figured the auber would take care of that.

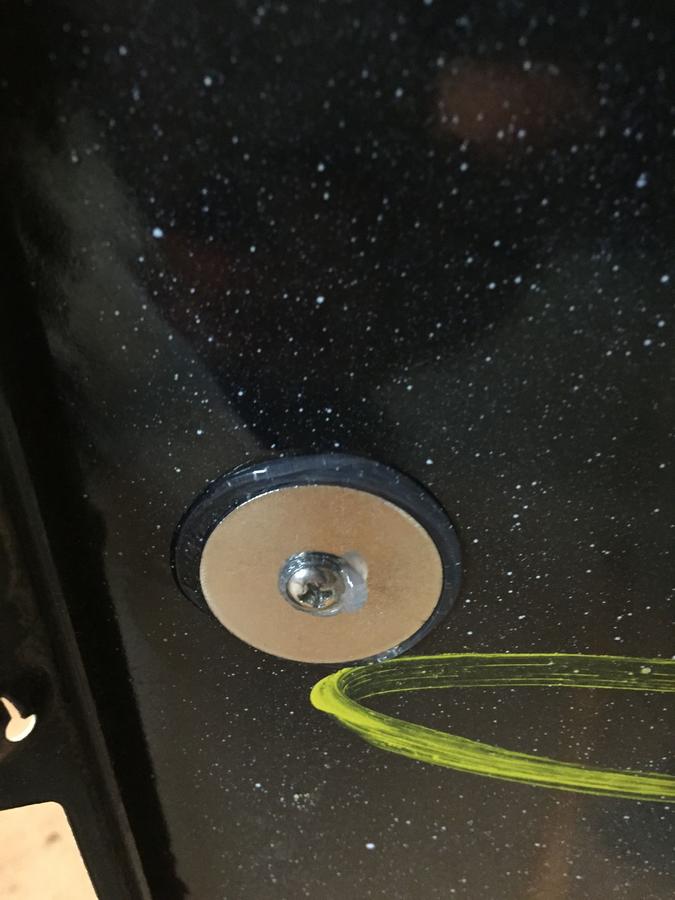

I think i lucked out on the door, it looks like its all steel except for the rubber gasket, so I plan to just take the gasket off, make sure it is all sealed and add a BBQ gasket.

Also I have the the lower part of the fridge hiding the compressor and plan to make some sort of hinge & door for it.

Thanks to everyone here for being so awesome & willing to share advice and insights.

![GALLERY]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

So it is finally finished! The Ugly Piglet made her maiden voyage. Here are just some quick thoughts or tips on if I had to do this again what I would do differently.

I will change any of these tips if I run into issues, and they are just my opinions.

1. Splurge on the Auber! Mine was the WSD-1500 model. You don't have to; especially if your budge is tight, but if you are going electric it is SOOO nice to have.

2. Rutland's 500F (or they make a higher one too) is AWESOME stuff. You can use it in -30F weather and still have it set right. Since this was my winter project, I needed that flexibility.

3. When you are cutting the holes with a hole saw, get some oil to lube the teeth and go nice and slow. If you try to force it the saw will sometimes walk and you'll have issues.

4. Intake and smoker's box; I used the AMPS and an ammo can. My intake (and only intake on the build) is only 1 1/2" diameter and it seems to be working great. If that changes I will update this tip, but I don't see why you need so many or large intakes for an electric build.

5. Used a 3" exhaust with no damper, just don't see the need in a damper, but it probably personal preference.

6. The black tarry cement that came with the gasket I thought was garbage. Didn't work right, but that maybe due to the 30 degree weather too.. Used the Rutlands silicone and it works great!

7. Was not able to use the original door latch so I bought on amazon a Uxcell Toolbox Toggle Latch. This thing is serious!! bigger than I thought and works great!

8. Get a Strip fin heater, again if budget allows. It is a little more work to wire it up, but probably would be better than the 1500 watt replacement element I have. Not that the element is bad, because it isn't; infact in 30 F weather I heated to 225 in 40 minutes… that is pretty good in my book. The Stripped fin heaters from Grainger just have a smaller foot print and I think would've been easier to install.

9. Have fun! Be patient and read read read

Responded to an ad on Craigslist list & initially turned him down because I thought it was to small. Well he contacted me at the beginning of the week saying that his wife wanted it gone & he would give it to me for free. How could I say no?? So I picked it up on my way to an estate sale.

From what I can garner in my quick research online, it is a 1948 GM Frigidaire. I ordered an Auber PID, Brinkmann 1500 watt element. I also picked up a 3" exhaust with rain cap, some stainless steel rivets.

I'm wondering if I plan to do 1" steel intake into a AMPS ammo box, will that be enough of air intake? There isn't a damper on the exhaust, figured I would add a 2nd intake with damper if i needed more control, but figured the auber would take care of that.

I think i lucked out on the door, it looks like its all steel except for the rubber gasket, so I plan to just take the gasket off, make sure it is all sealed and add a BBQ gasket.

Also I have the the lower part of the fridge hiding the compressor and plan to make some sort of hinge & door for it.

Thanks to everyone here for being so awesome & willing to share advice and insights.

So it is finally finished! The Ugly Piglet made her maiden voyage. Here are just some quick thoughts or tips on if I had to do this again what I would do differently.

I will change any of these tips if I run into issues, and they are just my opinions.

1. Splurge on the Auber! Mine was the WSD-1500 model. You don't have to; especially if your budge is tight, but if you are going electric it is SOOO nice to have.

2. Rutland's 500F (or they make a higher one too) is AWESOME stuff. You can use it in -30F weather and still have it set right. Since this was my winter project, I needed that flexibility.

3. When you are cutting the holes with a hole saw, get some oil to lube the teeth and go nice and slow. If you try to force it the saw will sometimes walk and you'll have issues.

4. Intake and smoker's box; I used the AMPS and an ammo can. My intake (and only intake on the build) is only 1 1/2" diameter and it seems to be working great. If that changes I will update this tip, but I don't see why you need so many or large intakes for an electric build.

5. Used a 3" exhaust with no damper, just don't see the need in a damper, but it probably personal preference.

6. The black tarry cement that came with the gasket I thought was garbage. Didn't work right, but that maybe due to the 30 degree weather too.. Used the Rutlands silicone and it works great!

7. Was not able to use the original door latch so I bought on amazon a Uxcell Toolbox Toggle Latch. This thing is serious!! bigger than I thought and works great!

8. Get a Strip fin heater, again if budget allows. It is a little more work to wire it up, but probably would be better than the 1500 watt replacement element I have. Not that the element is bad, because it isn't; infact in 30 F weather I heated to 225 in 40 minutes… that is pretty good in my book. The Stripped fin heaters from Grainger just have a smaller foot print and I think would've been easier to install.

9. Have fun! Be patient and read read read

Last edited: