The way I have mine calculated the cut out on the CC Tank for the FB will be 1 3/16 taller than it normally would be for the double wall top on the FB. When looking into the CC at the FB the RF Plate will step down the to the ceiling height in the FB. So you will actually see the step with your eyes when looking in if that makes sense.

**New Member = First Reverse Flow Smoker Build from 60 Gallon Compressor Tank**

- Thread starter mad dart

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

inkjunkie

Master of the Pit

- Nov 25, 2014

- 2,020

- 50

Sorry or having such a hard time understanding this. So if I understand you correctly the insulation is sandwiched between 2 layes of steel, a firebox within a firebox type of thing? If this is true does the bottome of the box get insulated as well? What about the door? If one were to include a slide out ash tray in the FB does this change anything?Usually, you build the firebox, weld it to the CC, then insulate the outside of the FB. Some guys tack roofing nails or similar spikes to hold the insulation in place before welding on the outer skin. You can use a strip mounted at a 45 on the corners and weld the skin to that or I've seen guys weld square tubing on the edge to also do the same thing. You can use cardboard to make a template before you cut the skin metal. The outer skin does not have to be as thick since it isn't exposed to the caustic fire environment. If Gary comes along, he did one recently and should have a link to his thread. I suck at digging through the archives.....

If the insuation is going to be sandwiched between two layers can the firebox be contructed out of thinner steel? Local metal yard quoted me $266 if I remember right for a 4x10 sheet of .250", if I will be building a double walled FB quessing I will need a bit more than this, once it i all figured out. I have only found one shop in town that sells "recycled" steel, and there inventory is really hit or miss...

lendecatural

Smoking Fanatic

There is no need to insulate the bottom of the firebox and the door isn't much of an issue either. The heat wants to go up, so the top is the biggie, and the sides are easy since you are putting the vents in the door. Cool air comes in the door so it won't be getting as hot. You can get away with thinner metal for the outer skin. Thats why I was saying you could mount the firebox like a normal smoker then fit insulation up using thinner metal. The upper firebox skin would have a dish cutout to match to dome of the CC.

Build the inner box that will be exposed to fire out of 1/4" and you can skin the outside with 1/8" and tack it in place or weld it solid. You just have to be careful not to warp it, stitch weld around before you weld it up. It won't get as hot so you could use RTV on the seams if you want.

Does that help?

Build the inner box that will be exposed to fire out of 1/4" and you can skin the outside with 1/8" and tack it in place or weld it solid. You just have to be careful not to warp it, stitch weld around before you weld it up. It won't get as hot so you could use RTV on the seams if you want.

Does that help?

FYI - I got 3 quotes for all of the plate steel I will need. This is California so you back east guys might throw a fit! Lol

All pieces pre cut ready for pick up are right at $300.00, Double wall firebox out of 3/16 material. The bottom is not getting double walled. I will probably still do the door double walled. I like the feel of closing a Safe Door! Lol

RF Plate is out of 1/4" material.

3 pc - 23 1/4 x 19 3/4 x 3/16"-----$22.50/ea

2 pc - 23 3/4 x 19 3/4 x 3/16"-----$22.50/ea

3 pc - 23 3/4 x 23 3/4 x 3/16"-----$27.00/ea

2 pc - 21 7/8 x 19 3/4 x 3/16"-----$21.00/ea

1 pc - 21 7/8 x 20 1/2 x 3/16"-----$22.50/ea

1 pc - 17 x 38 x 1/4-----$45.00/ea

Total = $303.00

I will be ordering it on Monday.

All pieces pre cut ready for pick up are right at $300.00, Double wall firebox out of 3/16 material. The bottom is not getting double walled. I will probably still do the door double walled. I like the feel of closing a Safe Door! Lol

RF Plate is out of 1/4" material.

3 pc - 23 1/4 x 19 3/4 x 3/16"-----$22.50/ea

2 pc - 23 3/4 x 19 3/4 x 3/16"-----$22.50/ea

3 pc - 23 3/4 x 23 3/4 x 3/16"-----$27.00/ea

2 pc - 21 7/8 x 19 3/4 x 3/16"-----$21.00/ea

1 pc - 21 7/8 x 20 1/2 x 3/16"-----$22.50/ea

1 pc - 17 x 38 x 1/4-----$45.00/ea

Total = $303.00

I will be ordering it on Monday.

Last edited:

lendecatural

Smoking Fanatic

That really isn't that bad considering it is precut. Measure three times, it would suck to get it back and you didn't include the wall thicknesses when you were laying everything out. Been there done that, not fun...

That really isn't that bad considering it is precut. Measure three times, it would suck to get it back and you didn't include the wall thicknesses when you were laying everything out. Been there done that, not fun...

Only 3 times? Lol, I did it at least 10! I'll do it a couple more times before Monday for sure.

Spent a couple hours on the project tonight. Cut off all the brackets, legs and laid out the CC Door.

When laying out the door, I at first was going to go 90*, but after looking at it , I ended up moving the hinge line 4" back from 90* so the door would be bigger. It just didn't look right.

So I cut all the way across the hinge side, all corners and stitch cut it out all the way around leaving about 1" between the cuts then sanded off the powder coat where the door seal will go. I need to get some Flat stock tomorrow so I can get the hinges set & cut out the rest of the door and finish off the flat stock all the way around for the door seal.

This weekend I should be able to put a pretty big dent in it.

When laying out the door, I at first was going to go 90*, but after looking at it , I ended up moving the hinge line 4" back from 90* so the door would be bigger. It just didn't look right.

So I cut all the way across the hinge side, all corners and stitch cut it out all the way around leaving about 1" between the cuts then sanded off the powder coat where the door seal will go. I need to get some Flat stock tomorrow so I can get the hinges set & cut out the rest of the door and finish off the flat stock all the way around for the door seal.

This weekend I should be able to put a pretty big dent in it.

Last edited:

darkshadow

Fire Starter

Nice and dusty so Zip disk for the cuts?

I only notice because that is one white

And clean shop!

I only notice because that is one white

And clean shop!

lendecatural

Smoking Fanatic

inkjunkie

Master of the Pit

- Nov 25, 2014

- 2,020

- 50

The way Louis works I am shocked it is not done yet.....come one now Louis, why are you butt dragging so bad??

Have given up, for now, on trying to understand how to insulate the firebox. I am hoping that Louis post some detailed pictures as he goes....hint hint....

Have given up, for now, on trying to understand how to insulate the firebox. I am hoping that Louis post some detailed pictures as he goes....hint hint....

Lol... My shop is a full blown mess... The bay I am working in is the cleanest part of it. If I posted full pictures of it you would understand!

I grabbed that horse and then quickly grabbed the VP Fuel drum & threw the tank up on them. The tank is level as all get out on the first whack. No adjustment needed... Pretty funny.

I didn't have time to break away today but for sure before Friday I will have most all of the materials, including the Firebox plate.

The plan is to go ape shit on it starting Saturday morning unless something else comes up......

I will take detailed pictures of all stages and post them up. I keep a pretty good diary of everything that I do

on my other project on different forums. This will be no different.

I grabbed that horse and then quickly grabbed the VP Fuel drum & threw the tank up on them. The tank is level as all get out on the first whack. No adjustment needed... Pretty funny.

I didn't have time to break away today but for sure before Friday I will have most all of the materials, including the Firebox plate.

The plan is to go ape shit on it starting Saturday morning unless something else comes up......

I will take detailed pictures of all stages and post them up. I keep a pretty good diary of everything that I do

on my other project on different forums. This will be no different.

Last edited:

Just ordered the FB material and YES my measurements were wrong! I fixed the order and paid. Pieces will be ready for pickup after 1pm today.

While I am there I will be picking up some of the other material that I will need.

While I am there I will be picking up some of the other material that I will need.

I picked up the pre cut FB today along with just about all the material I will need to finish it off except some wheels of some sort and the expanded metal. I didn't have room in my excursion for it so I will head back by Friday to pick up a sheet.

I am using 1 x 1 x 3/16 angle for the Cook Shelfs and slide outs. 1 1/2" x 1/8" flat stock for the door seals. 5/8 Round Stock for the FB Grate & 2" x 2" x 16 ga for the legs and lower rack.

I picked up 4 chipping hammers from Harbor Freight that will get used for door locks & upper vent control on the FB.

The insulation is quite a bit more than I will ever use. Could make 20 insulated FB's with what is in that bag.

I am using 1 x 1 x 3/16 angle for the Cook Shelfs and slide outs. 1 1/2" x 1/8" flat stock for the door seals. 5/8 Round Stock for the FB Grate & 2" x 2" x 16 ga for the legs and lower rack.

I picked up 4 chipping hammers from Harbor Freight that will get used for door locks & upper vent control on the FB.

The insulation is quite a bit more than I will ever use. Could make 20 insulated FB's with what is in that bag.

inkjunkie

Master of the Pit

- Nov 25, 2014

- 2,020

- 50

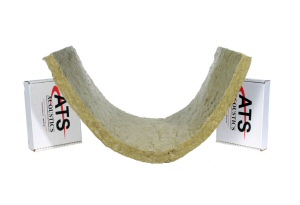

It is in aisle 24 at the local HDHere is what we use :

[h1]Roxul Acoustical Fire Batts, Mineral Wool, 2-inch (6PK)[/h1]

Point to an image below to see a larger version.

- Price and Order

- Item Description

Price: $36.00

- Jan 6, 2011

- 26,255

- 4,705

Cool That is what you need to insulate a smoker, The house insulation is not good for that. House insulation when compressed looses it's R value and tou probably dont want 6" of insulation. When we finished you could hold you hand on the side, door and back.

Last edited:

It is the same stuff. Rated to 2150* + , It is just thicker than your material is all.

I won't be compressing anything. It will be cut to size.

I won't be compressing anything. It will be cut to size.

I got the door cut in, the door seal installed and the hinges set and everything welded off.

The hinges were pretty easy to set. They took me about 15 min total time. I used 2 straight edges, bam done! The door seal welds will stay exposed but I will grind down and smooth out the 4 welds that joined the seal at the corners together.

I will probably make up and finish off the CC grates, CC Door Handle & Latches along with cutting out the FB Opening and set the Plenum before I move onto the FB.

The hinges were pretty easy to set. They took me about 15 min total time. I used 2 straight edges, bam done! The door seal welds will stay exposed but I will grind down and smooth out the 4 welds that joined the seal at the corners together.

I will probably make up and finish off the CC grates, CC Door Handle & Latches along with cutting out the FB Opening and set the Plenum before I move onto the FB.

Last edited:

Nice work on that smoker! Looks bad ass!

Cool That is what you need to insulate a smoker, The house insulation is not good for that. House insulation when compressed looses it's R value and tou probably dont want 6" of insulation. When we finished you could hold you hand on the side, door and back.

Did you make those wheels or buy them somewhere?

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 215

- Views

- 11K

- Replies

- 3

- Views

- 900

- Replies

- 10

- Views

- 472

- Replies

- 3

- Views

- 1K

- Replies

- 35

- Views

- 1K

Hot Threads

-

Chorizo or Sausage? Help a newbie!

- Started by I-am-Chorizo

- Replies: 53

- Sausage

-

Getting to the bottom of what happens to cure in smoked sausage

- Started by hog warden

- Replies: 25

- Food Safety

-

Ready For The Farmers Mkt

- Started by BGKYSmoker

- Replies: 24

- General Discussion