I'm a little late getting to the party on this one, but here we go....I would like some help with the mypin controller. I want to run this on proportional, in other words, the voltage output varies with the demand. I'm using a 3-32DCV SSR. I'm not sure what the controller settings should be, but here is the current settings that seem relevant, most are controller default.

PUF 0.0

P 33

I 24

d 0.04

hys 100

ctl 001 also tried on 020

The voltage to the SSR is aways around 1V no matter on the demand. The second SV number (I assume this is the proportional % output) does change, OUT1 flashes like it's is delivering proportional. It looks like it's working but without voltage output to the the SSR.

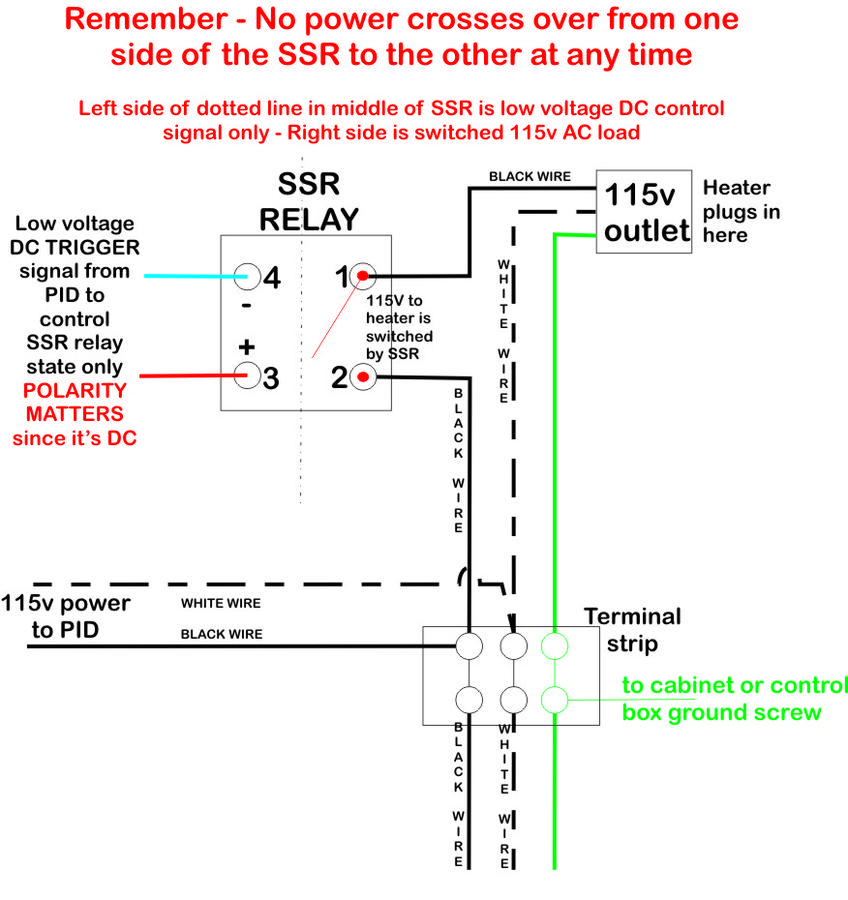

As to "proportional", the MYPIN will not vary the voltage proportionally to a SSR. An SSR sees a triggering voltage, which can be within a certain wide range, and it then flips "on" like a mechanical relay, just with no moving parts. In essence it is a digital switch controlled by a DC triggering voltage. In your post quoted above you are using a 3 to 32v DC triggered SSR so any voltage between 3 and 32 volts DC will give the same result. The SSR triggers and the load on the output side is powered (the digital switch closes completing the power circuit). 3 volts does not give any different response than 32 volts so the value of the voltage is irrelevant as long as it is in the acceptable working range of 3 to 32v DC.

A PID is a three mode controller. PID stands for proportional-integral-derivative, and the three values are normally working in concert with each other to perform the desired function. To just use a controller as proportional mode only unit defeats the whole purpose of using a PID. The output is generally either a static relay or a DC triggering voltage in 99% of the MYPIN's I've seen. There is a way to manually set the proportional value if an auto-tune fails, but again the output is a either a static relay or DC triggering voltage.

If you are wanting a variable voltage output , it has to be a certain configuration MYPIN (output type code is "D"). Variable voltage will not work in concert with a SSR either. Variable voltage output MYPIN's are not that common, but they are out there. The most common will have SSR triggering output and/or static relay output. What model do you have? (should be on the sticker - post the full model number and a photo of the sticker would be best).

![IMG_20140322_163725_684[1].jpg](/media/img_20140322_163725_684-1-jpg.298214/full?d=1507227868)