I'm about to build a smoker and had a couple questions. Also if you have any tips/tricks, please share them. I will post pics of progress as I go.

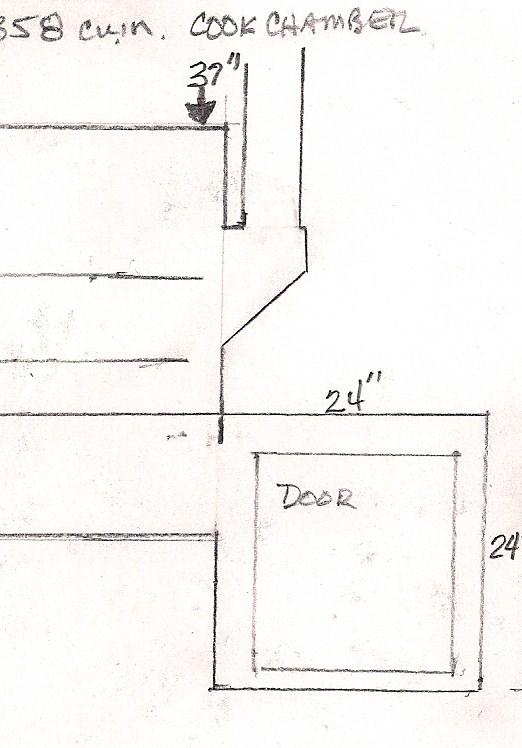

It will be 24" x .300 wall pipe, 4 ft cooking chamber and 2 ft fire box. Single door on the chamber with 2 slide out racks. Fire box will also have a slide out rack for burgers or steaks when needed, and will have a warming area on top of the fire box.

How big does the hole need to be between the firebox and cooking chamber?

Also, when I weld the firebox to the cooking chamber, should the top of the fire box be about at the mid-line of the cooking chamber? Or should it be lower?

Thanks for any help. Im cutting the pipe and end plates today and will probably get started with the build next week.

It will be 24" x .300 wall pipe, 4 ft cooking chamber and 2 ft fire box. Single door on the chamber with 2 slide out racks. Fire box will also have a slide out rack for burgers or steaks when needed, and will have a warming area on top of the fire box.

How big does the hole need to be between the firebox and cooking chamber?

Also, when I weld the firebox to the cooking chamber, should the top of the fire box be about at the mid-line of the cooking chamber? Or should it be lower?

Thanks for any help. Im cutting the pipe and end plates today and will probably get started with the build next week.